The proportions of concrete for the foundation: the rules of self-mixing

The main part of any building or structure is the foundation. After all, everyone wants his building, be it a house or a garage, to serve as long as possible, coping with the tasks set. Therefore, the main task is to build a strong and high-quality foundation. The characteristics of this node are not only accurate calculation, competent tab, but also in high-quality concrete. If the concrete is done personally, then you need to know in what proportion to mix the components that strongly affect the final result.

Special features

Not quite right to call concrete - liquid.Concrete is a stone made up of components. The official name is a concrete solution. Speaking more openly about cement, it is a binder that holds all the components together, which become one after settling. The main property of concrete - a high rate of hygroscopicity. Because of this, it must be supplied shortly before the preparation of the solution.

Components

The composition of the concrete includes several components.

- Cement. It is the basis for the solution.

- Water. It is a necessary reagent.

- Sand. The thickener that makes the solution is just painful. The density of the solution also depends on its quantity.

- Aggregate. There may be fine-grained gravel, and brick dust. There are options with larger aggregates. This affects the strength of the concrete and its bearing properties (brand).

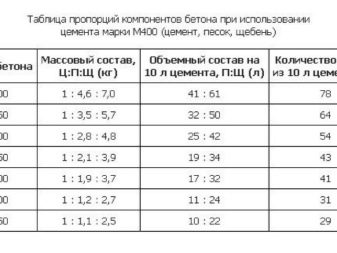

Sand mixture M 500, made by ASG, should be thoroughly mixed during mixing, so that the consistency is thick. Knead correctly will help a special table.

Kinds

The following types of cement are distinguished depending on the composition.

- Portland cement (ordinary). Intended for use under normal conditions.Perfectly tolerates the effects of both moisture and low temperatures. It is mainly used for the construction of foundations in ordinary buildings, most often in individual residential buildings.

- Slac Portland cement. Much greater moisture resistance than the previous one. The same applies to strength. It hardens much more slowly than usual. The main scope of application - areas with high humidity, with a usual climate and very rare frosts.

- Pozzolanic portland cement. WITHThe most resistant cement to moisture, but has the usual strength. Designed to fill structures that are not designed for heavy loads. Often - it's underwater structures.

- A special class of cements - fast-hardening. This is due to special chemical components that allow this solution to harden twice as fast as usual - in 14 days. Climatic conditions for this solution are not fundamental.

Almost any kind of water can be used as water, including tap water, as long as it is not rich in salts. Entering into a chemical reaction with water, dry cement is converted into the solution itself.

Sand should not include impurities of clay or other, the same allowable value of up to 5%. The grain of the sand should be around 1.2 - 2.5 mm of each grain, smaller for the future of the concrete will not work.

The best sand for the foundation is considered river sand, but washed and sifted. This is due to its constant washing with fresh water, which has a positive effect on clay and salt composition. As a filler, crushed stone is often chosen for the manual production of concrete, the grain fraction of which is within 15-20 mm.

But it is important to remember that the size of the grains should be about the same in the total mass, without a clear advantage of large rubble over small gravel. This is necessary to reduce the number of voids inside the concrete, which reduces the consumption of cement. It also should not contain clay impurities, garbage.

Concrete Marking

The concrete grade is indicated by the letter “M” and the digital value, which indicates the compressive strength of concrete, in kg / cm2. This density at the setting of concrete, which according to the SNiP is 28 days. This does not apply to quick setting cements and concrete. It is a mistake to believe that concrete is not below M100 grade; M50 concrete is used to fill small structures, often with fine-grained gravel.

The line of concrete starts from M15 and ends with M1000.Up to M200, concrete is mainly used on non-supporting structures, auxiliary or decorative. M200 or M300 are commonly used for foundations, and M350 for high-rise construction.

The minimum grade of cement is M100. The maximum cement brand is M500, but M1000 concrete. Concrete of this brand is super heavy, it is practically not used because of its high price and specific conditions.

One of the largest applications is to extinguish the fire of the fourth reactor at the Chernobyl NPP in 1986. The filler was lead ingots, which were discharged separately from the concrete. And also air-raid shelters were made of concrete of this brand, where the wall thickness reached 5-7 meters.

Since the liquidation of the Chernobyl accident, it was used in Russia and the CIS only once - during the construction of the Vostochny cosmodrome.

How to calculate?

From well-chosen components, as well as their proportions depends on how reliable and durable the construction will end up, be it a foundation or a wall. If you take the calculated ratio that is used at the factory, it may turn out not very high-quality mixture due to the fact that the components used there are peculiar and time-tested.At the factory, the formula is as follows: cement (1), sand (2), crushed stone or other aggregate (4), water (0.5).

When building with the manual manufacture of concrete is better to follow the same technology, but with minor adjustments. For M100: cement (1), sand (4), crushed stone or other aggregate (6), water (0.5).

But for a clearer understanding of the issue, we cite as an example the calculations for one cube: cement 205 kg, sand 770 kg, crushed stone 1200 kg, water - 180 l. But often there are no scales at hand, especially those that can calculate large weights, because the easiest way is to use improvised means, such as a bucket. A 10 l bucket is required, preferably with galvanization. Concrete of the M250 brand will be the best option for the base. Its proportions are: cement (1 bucket), sand (2 buckets), gravel (3.5 buckets), water (half a bucket).

Recipes

Low-rise buildings and structures (up to three floors) require a good foundation. Of course, it depends both on the territorial location and on the upcoming constructive load. Since the foundations with concrete pouring are tape-weighted, it can be assumed that this will be applied in the middle lane not in seismic areas, since the use of such foundations is prohibited in such areas.

In the case when the pressure on the centimeter of the sole of the grillage is more than 400 kg, then a concrete grade of at least M350 with proportions of cement (1), sand (1), crushed stone (2.5), water (0.5) is selected.

If the parameters of the future load are unknown, and the customer also has no idea about this, it is better to be reinsured and make heavier concrete М450 with proportions: cement (1), sand (1), crushed stone or other backfill (2), water (0.5) . Such foundations are much more expensive than their less strong counterparts at least three to four times, judging by the M200, so it is worthwhile to also carry out an economic calculation and expediency of pouring heavier concrete.

But if ay are going to use the M100, then this idea should be abandoned, if it is, of course, not a country porch or a small building.

Making concrete with your own hands

The main tool for making concrete is a concrete mixer, as well as a shovel and bucket. And also need a few buckets and car (stretcher). But if there is no concrete mixer, then it is possible to prepare a solution using available tools. For this you need some kind of wooden box, a plastic bath, although a metal one will do.In addition, two shovels, a pair of buckets. Of course, it is desirable to take a car. The rest of the tools include tamper, level, tape measure and meter, and also do not forget about the rules.

To postpone only for cement a bucket and a shovel, they should not get moisture. Although you can use the usual paint knife, making an incision on the bag and pouring cement directly into the container. For sand and rubble, we also set aside a set of shovels and buckets that should not be in contact with the cement. After preparation, you can begin to manufacture cement, carefully weighing the required amount with buckets.

After receiving the cement mortar, you must add gravel and sand, then mix thoroughly until a uniform layer appears. It is easiest to mix, making a tunnel under the solution and with vertical movements afterwards to “divide” the solution.

This allows you to knead almost all the components, lifting from the bottom what reacts badly. After that, make a “pyramid” of arbitrary angles, shapes and make a recess in the center of half the thickness of the dry mix. After that, add the required amount of water and begin to mix in exactly the same way as the dry solution.After complete mixing and dissolving of water, repeat the procedure with a “pyramid”. And so on until the entire solution is saturated with water and becomes concrete. The life of such concrete is about two hours, because immediately after preparation it is necessary to work with it.

Tips

For proper mixing, you can use the advice of professionals.

- If the solution is too thick, it can be diluted with a small amount of water so that the structure of the mixture is homogeneous. You should not be zealous with quick stirring, rather ordinary stirring.

- When working in wet weather or rain, as well as in cases where the sand is wet, the proportions of water must be reduced.

- The initial setting of concrete occurs after 12 hours. Primary hardening in 7 days from the moment of filling. After 14 days, the concrete is gaining two thirds of its strength, and after 28 days, it is ready for further work or operation. This applies to favorable weather conditions that do not affect the concrete constructively.

- Concrete work is not done indoors only in a season, that is, at a temperature above zero, since then an adequate chemical reaction occurs without delay and that is what is required.If concrete is kneaded and poured into frost, then ice particles are formed inside, which is very bad, because they take the lion's share of concrete strength, destroying it due to cavities, and repairing and restoring the foundation is a very expensive undertaking.

Of course, with the development of technology, special additives to the solution have appeared, which make it possible to exploit this very solution, making from it designs that are suitable for almost any region. In addition to frost resistance, you can add additional moisture resistance and water permeability properties. This has a positive effect on the properties of the future structure, allowing to build houses where previously only heavy and expensive concrete was used.

To learn how to mix concrete, see the following video.