Self-compacting concrete

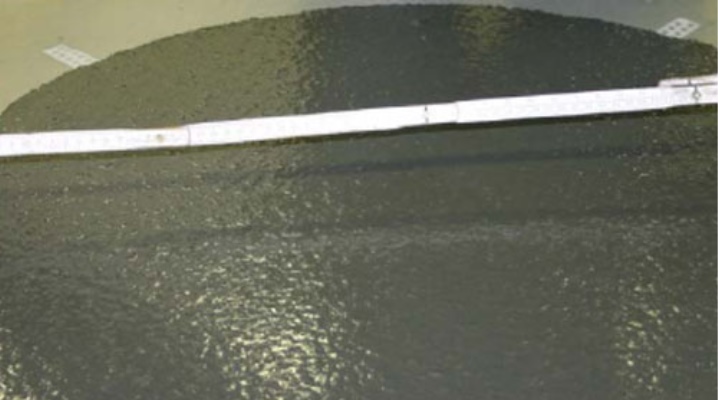

Self-compacting concrete is concrete that has the ability to fill a form even in densely reinforced structures due to compaction under the influence of its weight.

Features and Benefits

The solution for self-compacting concrete has the property of high workability (up to 70 cm), being characterized by a relatively small ratio of water and cement (0.38 ... 0.4). The material is quite durable (about 100 MPa). The risk of corrosion due to good material density is minimized. Polymer polycarboxylate is the main part of the composition and works as follows. It is absorbed by the surface of the cement grains, a negative charge is transmitted. For this reason, the grains repel each other, thus forcing the solution and mineral elements to move.The effect of plasticization may be enhanced by periodic mixing.

The advantages of concrete of this type are low noise, reduced construction time, the possibility of long-term transportation of the mixture, high-quality surfaces of products, there is no need to use a vibro-compactor. In this regard, the cost of electricity has been reduced, and thanks to the absence of noise, it became possible to locate reinforced concrete products factories in cities.

A bit of history

In the late 60s - early 70s, they began to use high-strength concretes, which were improved with additives-super-plasticizers. For example, in 1970 they were used to build oil platforms in the North Sea. The use of concrete with superplasticizers has demonstrated its advantages, but the disadvantages were revealed when working with it. If the pipeline through which the mixture is fed is longer than 200 meters, then a stratification of the mixture and non-uniformity in the final product appear.

Also, when adding most superplasticizers at high dosages, it is possible to slow down the mixture setting. And when transported in 60-90 minutes, the impact of the additive decreases, and, therefore, decreases mobility.From the foregoing, it becomes clear that the work time increases, the strength and surface quality of the product become worse.

To eliminate the drawbacks, theoretical research and practical developments were applied:

- addition of micro and ultrafine aggregate to increase strength, protect against corrosion and material cracks.

- the use of multifractional filler for high strength.

- To regulate the properties, the newest types of chemical modifiers were created.

In 1986, after summarizing the accumulated experience, Professor Okamura called his development "self-compacting concrete."

In 1996, the RILEM group was formed, consisting of experts from a dozen countries, to create an instruction manual due to their high efficiency.

In 1998, the first international conference was held to study its characteristics with the assistance of 150 scientists and engineers from different states.

In 2004, a 205-DSC committee was created, headed by Professor Schutter, to create a classification of species that is needed to establish the purpose and scope.During the operation of this committee, 25 laboratories from various countries were used.