Block house with imitation timber: features and benefits

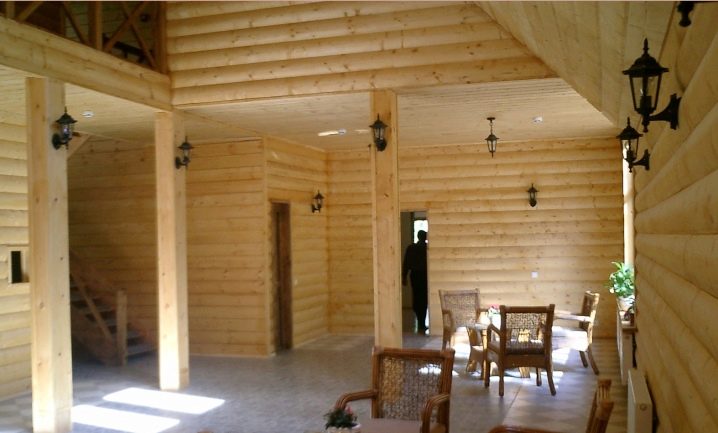

Block house is a popular type of facing board and is widely used for exterior and interior decoration of buildings. It perfectly imitates natural timber and gives the structure a natural and aesthetic appearance.

Special features

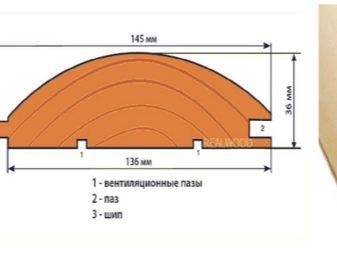

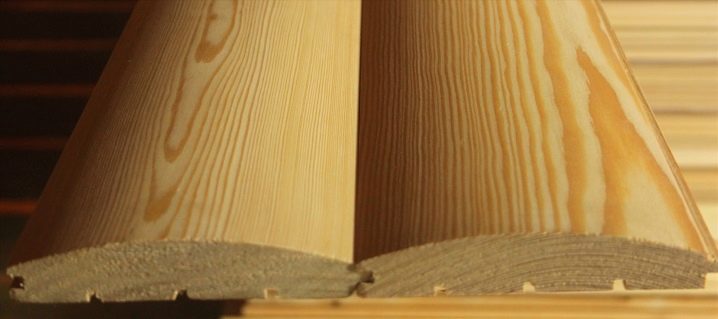

The block house is a planed wooden tongue-and-groove panel, the outer side of which exactly repeats the shape of the timber, and the inner one has an absolutely flat surface. The boards are interconnected by means of the tongue and groove system, which greatly simplifies installation and ensures a reliable connection between the panels. The material has gained great popularity among the owners of frame structures, allowing you to quickly and inexpensively elevate the building. The houses sheathed by a block house, it is very difficult to distinguish from natural, cut down from a bar. Such veneering gives the facade solidity, high cost and indicates the perfect taste of the owners.

A special feature of the manufacture of panels is the preliminary drying of wood.which is carried out in special chambers and completely eliminates the risk of longitudinal cracking of finished boards. In the process of processing, wood loses a lot of moisture, thanks to which the fins have a very low humidity, not exceeding 15%. This acts as a guarantor of the absence of mold and mildew, and excludes the appearance of a blue tint characteristic of undried wood. Dried board is not subject to the process of shrinkage and deformation, so that the panel is able to retain its original shape for a long time.

Specifications

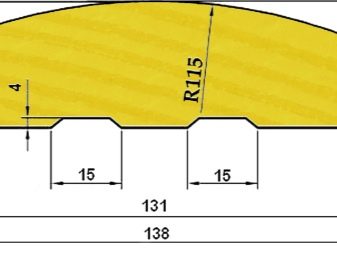

Production of block house panels is made in different dimensions. The length of the lamellae can vary within 2–6 meters, the width is 9–19.5 cm, and the thickness is 2–4 cm. Products with a width of 9–15 cm are suitable for interior decoration, and wide panels are better for exterior cladding. They make a block house from an array of hardwood and softwood. The first are represented by linden and oak, and the second by Arkhangelsk pine, cedar, Siberian larch and spruce. Softwood panels are the most valuable material.Due to the significant content of resin in wood, the waterproofing qualities of the board are significantly increased, the risk of wood damage by bacteria causing rotting is reduced, and the overall strength of the lamellae and their service life increase.

The wood of the Siberian larch is especially appreciated. The material has high hardness and moisture resistance, and therefore is the most expensive. Spruce and pine have good resin, sufficient strength and are distinguished by an optimal ratio of price and quality. Cedar boards are able to regulate the level of humidity in the room and contribute to the creation of a favorable microclimate. When buying a block house, remember that the best and most durable is northern wood.

Benefits

The popularity and high consumer demand for block house cladding panels are due to a number of positive qualities of the material.

- Versatility. The covering board can be used both for external, and for internal finishing. With the help of a block-house, you can not only elevate the façade qualitatively, but also perfectly sheathe a bathhouse, a veranda or a dwelling of a rustic and ethnic style.Wooden panels can be mounted on any type of foundation, including concrete, brick, wooden surfaces, as well as on walls of foam concrete and gas silicate.

- Absolute environmental safety and good ventilation of the facade give the material high hygienic properties. The facade maintains high vapor permeability properties, removing excess moisture through joining seams and wood, and in a room decorated with a block house, it is always easy to breathe.

- High resistance to mechanical stress. The material is well resistant to shocks and weight loads, the slats do not stratify and do not crack.

- Good maintainability. In case of damage to the board, the problem area is easily restored. To do this, it is enough to polish the defect and then varnish it.

- Low weight panels. Due to the lightness of the material, it is possible to achieve a significant reduction in the weight load on the bearing walls of the building and the foundation.

- High resistance to thermal pumps, high humidity, as well as to the conditions of high and low temperatures, allows the material to be used both in the conditions of the Far North and in the steam rooms of the Russian bath and Finnish sauna.

- The ease of installation is due to the presence of the universal tong-groove system, which allows for installation independently and in a short time.

- Excellent heat and noise insulation properties. The presence of a small space between the main wall and the lining of the block-house allows laying insulation, while providing reliable protection from cold and extraneous sounds. Reducing heat losses to a minimum will significantly save on heating the house.

- Aesthetic appearance and comfortable cost allow you to get a luxurious facade or stylish interior decoration for very little money. The material retains its original appearance for a long time, which eliminates the need for frequent repairs. It is recommended to renew wood panels with varnish at least once in 7 years.

- Good biological endurance and fire resistance of wood are due to the antiseptic and anti-foam treatment of raw materials carried out at the production stage.

disadvantages

In addition to the numerous advantages, there are some drawbacks to the material. Among them it is worth highlighting the need for periodic updating of the material with the help of varnishes, mastics, stain, and antiseptics.You should pay attention to the fact that the wood panels block house are slightly more expensive than the facing materials of artificial origin. Another disadvantage is the flammability and low moisture resistance of some types of panels. But this applies to the most budget, not the last special processing models.

Species

Block house with imitation of timber is made not only from natural wood. Vinyl and metal are often used as raw materials.

Metallic

Metal panels are made of galvanized steel. The front side of the plank is covered with a polymeric material that perfectly imitates the pattern of wood fibers. The advantage of a metal block house over a wooden one is a long service life of several decades, low cost and no need for regular updates.

At the production stage, the panels are coated with an anti-corrosion compound., preventing the destruction of metal and rust. Due to the incombustibility of the material, the overall fire safety of the building is increased. The disadvantages of a metal block house include the formation of the greenhouse effect indoors and the need to install additional fastening structures.

Plastic

Plastic panels that are made of vinyl are more suitable for interior decoration. The front side is covered with a polymer film, with a woody pattern printed on it. The advantages of this type are low cost, a huge selection of colors and textures, complete environmental safety and hygiene. The slats are lightweight, easy to install, easy to maintain and do not need regular updating. The material is not subject to rotting, not of interest to rodents and insects, eliminates the appearance of mold and fungus. The disadvantages include sensitivity to temperature differences, the need for interpanel gaps, and a less spectacular appearance when compared with wooden models.

Installation Features

Facing panels block house consists of several stages.

- It should begin with the preparation of the surface, which is to remove from the base of all the protruding elements: window sills, platbands, electrical wires, lanterns and curtain rods.

- The wall should be cleaned of dirt, putty large cracks, chips and deep depressions.

- The base must be covered with any waterproofing material, for example, pergamin.Cloths are mounted overlap and secured with aluminum tape.

- The next step should be the installation of crates. The distance between adjacent bars should correspond to the width of the insulation sheet.

- Wooden bars should be fastened with fasteners designed specifically for the material of which the wall is made. For example, on a brick or concrete base, the timber is fixed with dowels, and for a wooden surface it is enough to use screws.

- Care should be taken to ensure that the bars are installed in a strictly upright position. For mounting accuracy, you must use a building level or plumb. The bars should be framed doorways, windows, corners and transverse joints of the block-house panels.

- After the installation of the bars, you should proceed to the installation of insulation plates that are attached to the facade with the help of umbrella-shaped dowels or special glue. If mineral wool was used as insulation, then it should be covered with a moisture-proof membrane. At warming with polystyrene foam or polyfoam laying of a membrane is not obligatory.

- Further it is possible to start installation of a block house.The installation should be carried out from below, checking with the help of the level the horizontal position of the first board. The panel is attached to the crate with screws, klyymer or nails.

Install the strips should be a groove down. This will help prevent rain and snow from entering the lining, and will save wood from excessive moisture and swelling.

- When installing a block house, leave small gaps. This will prevent deformation of the cladding, which may arise from the expansion of wood as a result of abrupt changes in climatic conditions.

- The final stage should be the installation of visors, wiring, window sills, platbands and lanterns.

The internal installation of panels is carried out using the same technology, with the exception of laying insulation plates and membranes.

Tips for choosing

It is recommended to bring the material to the site in advance in order to allow the wood to adapt to the external conditions and the microclimate of the installation site. This will allow panels to gain the necessary moisture, as well as save them from further changing the shape of the panels. For exterior trim it is better to choose coniferous wood growing in the northern regions.Hardwood can be used for interior decoration. When purchasing a material, you should check the availability of certificates of conformity and other accompanying documentation, and visually inspect the panels for knots and other defects.

Block house is a great simulator of timber. It noticeably transforms any structure, giving it solidity, high cost and style.

For information on how to veneer the walls inside the house with a block house, see the following video.