“Block-house” decoration: installation details

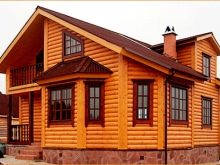

A block house is a popular finishing material used to decorate the walls and facades of various buildings. It has an attractive appearance and simple installation. It is possible to use this finishing both for external, and for internal finishing. Today we take a closer look at the subtleties of mounting such a lining.

Special features

The block house is rightfully recognized as one of the most common and popular finishing materials. The overlappings sheathed by similar coverings look as if built from natural wood.

The block house is made of wood and galvanized steel. The latter material is additionally covered with a polymer-based film. Such finishing coatings are double and single.

Both deciduous and coniferous trees are used in the production of these materials. The most durable and durable are coatings made from coniferous wood, because they contain natural resins. Such components provide natural waterproofing of the finishing material.

In addition to wood, metal versions of such finishes are also available - metal siding. Such coatings are made of galvanized steel, not subject to corrosion. These materials often imitate natural wood and look natural.

Quality block house is made on machines with special cutters. Wood processing has a direct impact on the quality of the finished product.

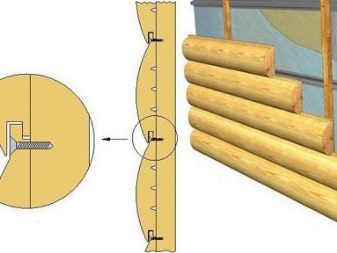

The block house is distinguished by its shape. It has a rounded anterior and flat posterior wall. On the edges of these materials there are spikes and grooves, which are necessary for joining the lamellae on the base.

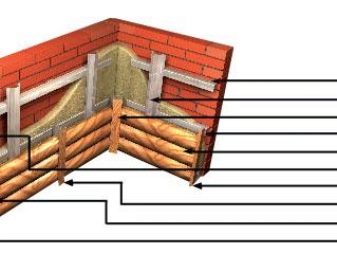

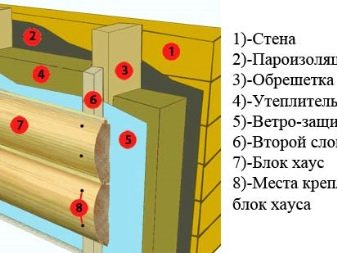

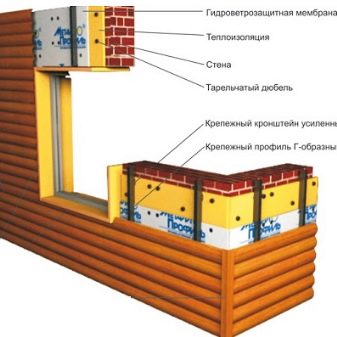

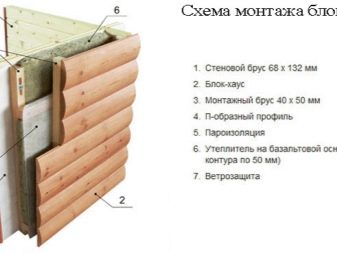

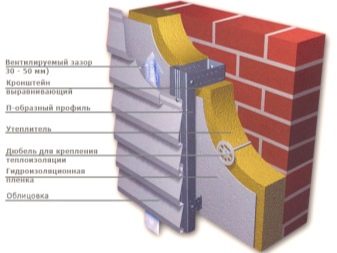

The ventilated facade, decorated with this finishing material, consists of several important components.

- In such structures should be of high quality vapor barrier. This component protects the block-house from steam and high humidity. Paroizolyatsionny layer passes through a pair in the direction of the floors, not allowing them to get to the insulation sheet.

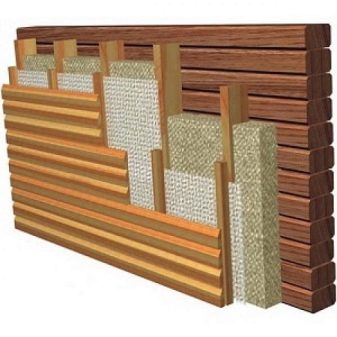

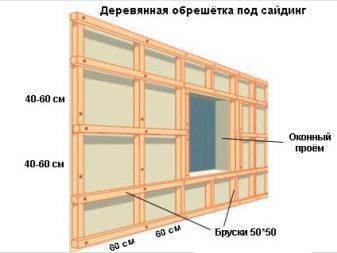

- Also, such facade systems have a crate (frame). It forms the space between the wall of the house and the block house itself. This component acts as a basis for fixing the rails. As a rule, the crate is made of a wooden bar with a cross section of 100x40 mm or 50x40 mm - this parameter depends on the material of which the heat-insulating layer consists.

- Required in this design and the insulating layer. This is most often used inexpensive foam or mineral wool. Insulation should be at least 10 cm in thickness.

- Such facade systems must be equipped with a wind barrier. It is installed on the timber frame and protects the insulating layer from moisture, which is present in the ambient air.

- In the interval between the block house and the wind-proof film, as a rule, there is a counter-lattice. It consists of bars of a small section - 20x40 cm. If you do not use this element in the arrangement of the facade, the panels of the block house made of wood can quickly rot.

- The final is the facing layer of the block house.

All listed components must be present in the facade structure. Otherwise, the block house will not last long and will rot.

Species

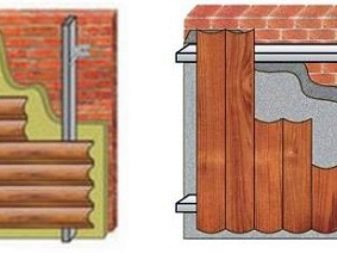

The block house can be made of metal and wood. Let us consider in more detail what characteristics these varieties of finishing materials possess.

Wood

For a start, it is worth considering what the wooden cladding of the house is good for:

- Such materials have a natural and expensive design. Buildings decorated in this way, look cozy and hospitable.

- Wooden block house is an environmentally friendly material. Its content does not contain hazardous chemical compounds. Even in high temperature conditions, such a lining will not emit harmful substances.

- The block house of wood is a wear-resistant material. It is not easy to damage or break.He is not afraid of shocks and mechanical damage.

- Quality panels are not susceptible to the formation of mold and mildew.

- The block house boasts excellent sound and waterproofing characteristics. In addition, this material will keep the heat inside the house.

- Installation of wood panels is simple and affordable. Even an inexperienced home master can cope with it.

The main disadvantage of a wooden block house is that it must be regularly treated with antiseptic agents. If we neglect such activities, then such material may rot, lose the brightness of the color and become a haven for tree parasites.

In addition, many consumers attribute the high cost to a number of drawbacks of a wooden block house.

For external cladding, a material with a thickness of 40-45 mm is used. Such coatings have enhanced thermal and sound insulation characteristics. They are able to withstand the effects of adverse external factors due to their thickness.

For the same interior use thinner slats with a thickness of 20-24 mm.Such coatings can only be used as decorative design elements. They are great for decorating the interior, because they are thin and do not take too much free space.

The block house is made of various wood species and is subdivided into several classes.

- "Extra". Such finishing materials are of the highest quality. They have a pleasant smooth surface on which there are not the slightest defects. Such a block house is expensive because it is subject to complex processing.

- "BUT". Materials of this class may have on their surface small knots, minor mechanical damage, as well as darkened areas. In some places, such a board may be uneven.

- "AT". A block house class may have cracks, knots and other noticeable defects.

- "WITH". Products of this class often have serious damage, visible cracks and knots.

For interior decoration is recommended to use a block house of class "A" or "Extra."

Metal

Now you should get acquainted with the positive characteristics of the metal block house:

- this material is not subject to deformation even under the condition of being in the mode of low and high temperatures (from -50 to +80 degrees);

- metal block house is a durable material. He can serve more than 50 years;

- this material is not afraid of sunlight and precipitation;

- the metal block house is an eco-friendly and safe material;

- it is not combustible;

- its installation is also considered quite simple;

- You do not need to take care of such finishing materials regularly, using expensive means;

- the metal block house can be laid out on the bases consisting of any materials, but most often with such material sheathed floors of the house or pediment;

- these panels are inexpensive, especially when compared with natural wood coatings.

The only and main drawback of the metal block house is its impressive weight. That is why it is possible to acquire such material only if the walls of the house are sufficiently strong and reliable. There is a lightweight alternative to this material - an aluminum block house. However, it is less durable. It can be easily rumpled and damaged.

Such finishing materials are more often used for exterior decoration. They look beautiful and natural. At first glance it is very difficult to distinguish them from natural wood.

How to choose?

Choosing a block house is not an easy task. Facing boards differ from each other not only in the materials from which they are made, but also in other characteristics.

Selecting similar materials of finishing, it is worth relying on recommendations of experts.

- For facing of a facade it is worth selecting not only thicker, but also wide panels. This parameter should be at least 15 cm. Choose coatings so that they have the same dimensions.

- It is recommended to buy longer slats. Using such materials, you can sheathe the house with the minimum number of joints. The standard length of the block house is 6 m.

- More dense and reliable are the boards from the northern regions. These features have a positive effect on the other qualities of similar materials. Find out the degree of density of the tree is possible using the arrangement of annual rings. The closer they are to each other, the more dense the raw material.

- Do not buy a block-house with various defects and damages, for example, rotten knots, cracks, dark spots or moldy plaque.

- Pay attention to the grinding - it should not have large sizes. The width of such elements should not exceed 8 mm, and the depth - 3 mm.

- The permitted moisture content of wood material is 20%. This indicator should be present in the quality certificate.

- Packing a block house should not be damaged. If they are present, then it is better to refuse to purchase the material, since it may be damaged or rotting.

Mounting points

The block house is mounted on a frame of wood or metal profile. With this method of installation from the inside there is constant ventilation, which allows to avoid penetration into the material and insulation moisture. Facade walls are constructed in two layers, so that insulation can be installed between them.

The block house needs to be attached to the bases horizontally. In this case, the spike should be directed upwards, and the groove - downwards.

The thorn-groove locking system is optimal for such finishing options.However, besides this, screws are used for fastening each bar outside. They are installed closer to the sides of the panel.

In addition to self-tapping screws, other elements are used to fasten the material:

- nails;

- Kleimer;

- galvanized brackets.

Billets for exterior trim are laid out horizontally. However, inside the building they can have a vertical location.

In the corners of the block house is recommended to fasten as follows:

- you must first secure the bar in an upright position;

- then it should be attached to the workpiece.

Using this method of fasteners, you eliminate the appearance of noticeable gaps.

On the areas of joints need to make additional zapily at an angle of 45 degrees. They are necessary to protect the finishing materials from deformation. This technique can be accessed with external and internal lining of the house.

Calculating the amount of lumber

Before proceeding to the arrangement of the facade of the house, you need to calculate how much blockhouse volume you will need.

Currently, these materials are available with various dimensional parameters:

- the width of the lamellae for finishing inside buildings is 96 mm, length - 2-6 m, thickness - from 20 mm;

- for exterior design, a board with a width of 100 to 200 mm, a length of 4-6 m and a thickness of up to 45 cm is used.

To find out how much block-house you need to buy to design your house, you need to know how many square meters in the ceiling. To do this, the width must be multiplied by the height. From the resulting value, subtract the area of the windows and doors. Now you can calculate the area of one panel and divide the total number by the obtained value. Do not forget that in these calculations you need to consider only the working width of the material (without locking elements).

For example:

- the length of the panel is 5 m, and the width is 0.1 m;

- multiply these values and get the result is the area of one panel - 0.5 sq m;

- if the total area of the wall is 10 square meters, then only 20 lamellas will be needed to finish it;

- if there are doors and window openings on the ceiling, then it is worth buying a block house with a small margin.

Step by Step Installation Guide

It is possible to decorate the overlap block-house with your own hands. Let's take a closer look at step-by-step instructions for laying such facing material.

You will need the following materials:

- special membrane for protection against wind;

- rolled insulation;

- vapor barrier film;

- primer;

- antiseptic composition;

- bars for the frame;

- Klyymery and screws for fasteners.

You also need to stock up on such tools:

- level;

- brush;

- hammer;

- Sander;

- saw;

- electric drill;

- screwdriver.

First you need to prepare the grounds:

- All wooden parts should be treated with antiseptics. It is desirable to cover the boards with fire retardant - it will protect them from fire and mold.

- To the walls of the house you need to nail a vapor barrier layer. The film should be fixed with an overlap of 10-15 cm. It is more convenient to perform such work with a construction stapler.

- Next, you need to install the crate. It should be horizontal. Assemble the bars should be using nails or screws. If we sheathe brick or panel walls, it is better to use frame dowels.

- In the open cell frame structure should be laid insulation.

- Attach to the main frame another layer of crates - vertical. To do this, the bars should be fixed with a level.It is on this basis that we will be laying the block house.

After that, you can proceed to the trim of the house with wooden or metal panels. To mount this finishing material you need, starting from the bottom corner. Mounting panels should be horizontal.

- Kleimer should be attached to the frame on the screws.

- In the mounting foot to insert the starting part. The position of the boards should be a groove down.

- The groove of the following elements must be put on the spike.

- The lining work must be continued until the wall is completely finished.

The block house can be installed inside the house. It can be laid out on the walls and on the ceiling of the room. In this case, the installation of the panels will be similar to outdoor installation.

It should only take into account the following nuances:

- for finishing indoors suitable narrow facing of small thickness;

- external and internal corners must be fixed only after the installation of the block-house is completed.

Recommendations

If for interior or exterior you have chosen a material such as a block house, then you you should read some of the recommendations from the experts:

- If you plan to put a block house on wooden floors, then first you need to properly clean the areas affected by the fungus on their surface.

- Dock materials should be especially carefully and carefully. In such processes, you must use the level to make sure that the docking is correct and smooth.

- The block house should not be installed on the floor immediately after purchase. It is possible to start repairs only after the panels have been left for several days under a shed or in a dry room.

- It is not recommended to use foam plastic for insulation, especially if you are installing a non-metal, but a wooden block-house. Such a heat insulator is incompatible with wood, as it supports combustion and does not have sufficient vapor permeability.

- During the construction process it is recommended to use clamps. Such parts create a secure fit. Conventional screws can damage the material, and a steel clip will gently fix the edge of the groove.

- A block house made of wood is not recommended for use in finishing rooms with a high level of humidity (kitchen, bathroom, toilet), otherwise the material will have to be regularly treated with protective compounds so that it does not become unusable.

- Experts recommend purchasing quality block house from proven manufacturers with a good reputation in your city. You should not look for materials for which a cube is being asked for too low a price.Such coatings are likely to belong to the lowest classes and are not distinguished by good processing.

In this video you will see the finishing of the house "Block House".