“Block-house” decoration inside the house: design ideas and installation methods

The block house is a modern finishing material made from wood. Finishing with such material not only gives the room an aesthetic appearance, but also allows you to create a favorable microclimate. This article will tell you about the peculiarities of finishing the block-house of the space inside the house, ideas of design and methods of installation.

Special features

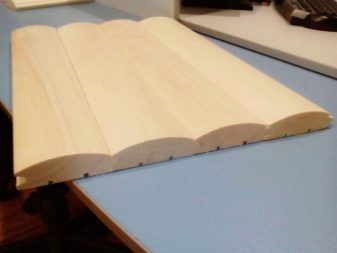

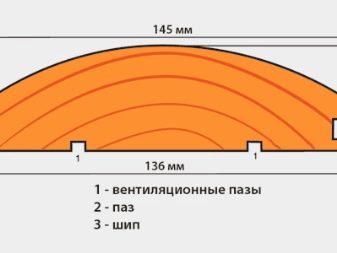

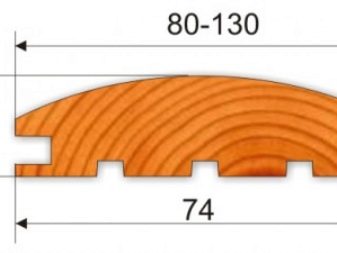

Block house is a kind of wall paneling. On the one hand, the surface of the panels has a convex shape, which visually resembles a log house or a rounded beam. For mounting on the material there are special spikes and grooves.

Block house is used for interior and exterior. It is possible to veneer a small area with a building material, since the thickness of the panels is not very large.

Products have a number of advantages.

- Safety for human health. Since the panels are made of natural wood, the block house is a fully eco-friendly material.

- Panels do not create a large load on the walls due to the fact that they have a small mass.

- The material provides a good level of sound insulation.

- The coating has thermal insulation properties. Of course, the panels do not provide absolute heat retention, but they minimize the influence of cold surfaces on the microclimate.

- The material is easily attached to the surface of walls and ceilings. The work does not cause difficulties even for beginners.

- A block house made of precious woods fills the room with a pleasant aroma, which creates a special mood and favorably affects the health of the household.

- Wood panels do not have to be used to finish the whole room. The block house is perfectly combined with other materials, they can decorate only one wall or its part.

Varieties of material

In the modern construction market, you can find many varieties of block-house, which differ in some parameters and characteristics.The main classification involves the allocation of several types of material, depending on its quality.

- "Extra". The panels "Extra-class" have no significant defects, are of excellent quality and high cost.

- Category "A". Panels of this category are of good quality. A small presence of healthy knots, resin pockets and traces of pests (wormholes) of a width of not more than three millimeters is allowed.

- Category "B". Material may have more significant surface defects. However, flaws should not spoil the operational and decorative characteristics of the panels.

- Category "C". Products of this class are low cost and the worst quality. The material has an unpresentable appearance and needs additional processing. Panels of this class can trim the walls of the outbuildings.

The performance of the block house is influenced by the wood species from which the material was made.

- Pine. On such a surface there are usually traces of knots that create an interesting pattern. Material can be used for both internal,and for exterior decoration of houses.

- Siberian fir. This material stands out among other coniferous trees the smallest weight. Fir contains little resin, so this wood is susceptible to rotting and requires additional treatment with antiseptic.

- Spruce. This material has a beautiful texture. Unlike pine, spruce has a lighter shade.

- Cedar. This wood has a pleasant aroma and a good effect on the indoor microclimate.

- Larch. This material is highly durable. Larch contains a large amount of resin, which protects the material from rotting.

- Alder. This type of wood is considered one of the most durable and moisture resistant. The performance characteristics of alder panels only improve over time.

- Linden. This coating is practically not exposed to high temperatures. Most often, a linden block house is used for cladding bath rooms.

- Birch tree. Wood has a uniform structure and is easy to process with paints and varnishes. With the help of birch panels you can create an imitation of almost any expensive wood.

- Aspen. Such panels are not subject to rotting, they are well tolerated by moisture and have high strength.

Wood panels can have different lengths, widths and thicknesses. Standard material thicknesses are 20, 30 and 36 millimeters. The width can vary from 90 to 190 millimeters. Intermediate values of the width of the produced material are usually 120, 140 and 160 millimeters. The length of the panels is usually two or six meters.

How to choose?

The choice of a suitable block house depends on several parameters at once.

When buying material should consider the following factors:

- floor space;

- interior design style;

- purpose of the room;

- type of surface to be trimmed.

For small apartments or rooms of a small area it is better to use panels with a minimum thickness. Such material does not "take away" a lot of space. For large rooms, you can use wide panels, which will allow you to create an imitation of rounded timber.

The block house looks good in such interior styles as country, rustic, Provence, Chebbi-chic. The panels are perfectly combined with other materials, for example with decorative plaster, natural stone or paint and varnish coatings. A block house can be finished only part of the wall, creating an interesting interior solution.

The panels are quite easily mounted on a variety of bases. Most often, the material is used for cladding brick, concrete, wood or metal surfaces.

The purpose of the room in which the cladding is planned to be carried out influences the choice of the type of wood from which the panels are made. In rooms with high humidity, moisture-resistant tree species will be the best option.

When choosing a block house is also important to pay attention to its quality. On the surface of the material should not be damaged or significant defects.

How to sheathe: step by step instructions

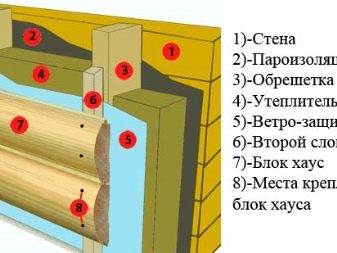

Wall cladding blockhouse can be easily done by hand. Installation work does not require thorough stripping and leveling the base, since the panels are mounted on the batten. Before proceeding with the main work, it is recommended that the inside and inside of the block house be treated with an antiseptic composition and dried at room temperature.

Surface preparation

To protect the base from the adverse effects of external factors and microorganisms, it is necessary to clean it of impurities and treat it with antiseptic impregnation.If there are significant irregularities on the surface, then the wall must be leveled with plaster or putty.

The main preparatory stage before paneling the block house is the installation of the frame. For crates used timber, whose thickness can be from three to four centimeters. Rails vertically attached to the surface with a gap of 50-65 centimeters with dowels and screws.

First you need to attach the slats in opposite corners of the room. When installing a timber in the corners of the first fixed its upper part. The correct position of the bottom is determined by the building level.

Between the rails installed, the rope is tensioned, then the rest of the structure is fastened, starting from the middle of the wall.

It is more convenient to attach the timber, starting from the top. After complete installation of the structure, you can proceed to facing works.

Installation

It is recommended to start fixing the block house panels from the bottom of the wall, moving to the ceiling. Between the first panel and the floor, you must leave a small gap (no more than a centimeter) to form good ventilation. The material is attached to the frame with screws.

Screws are screwed into the groove with a screwdriver at an angle of 30-45 degrees. As an alternative fastener, you can use special clears. The advantage of this mount is that it will be hidden behind the panels.

Each next panel is placed with a spike in the groove of the previous plank and fitted to a better fixation with a joiner's hammer. If wall cladding is carried out in a room with high humidity, it is recommended to leave a gap of a couple of millimeters between the panels. This will avoid block-block deformation.

It is not necessary to fix the material close to the ceiling, it is recommended to leave a small gap (five millimeters). The joints of the slats are masked by decorative corners.

Finishing work

After all the straps are securely attached to the crate, it is recommended to level the surface with a grinder. To improve the performance characteristics of the wood must also be treated with antiseptic and fire-impregnated.

The gaps that were formed during installation between the slats and the floor, as well as the slats and the ceiling, must be closed with plinths.To give a more aesthetic look to the covering, the block house can be treated with paint, varnish or stain.

For painting the surface it is better to use water-dispersion formulations in order to preserve the natural structure of wood. The technology of applying paintwork composition does not differ from similar processing of any other wooden structures.

To protect and decorate the panels, you can use a natural wax coating. The surface covered with wax is not so demanding to care. It is enough from time to time to remove dust from it using a dry cloth or a vacuum cleaner.

Room Design Examples

Wood looks great in the interior of the kitchen. Light panels fill the atmosphere with warmth and comfort.

The block house of moisture-resistant wood can be used in rooms with high levels of humidity. Wooden panels painted white look great in a Provence-style bathroom.

Wood panels are often used for finishing attic floors. The material does not create a large load on the walls, improves the level of heat and sound insulation.

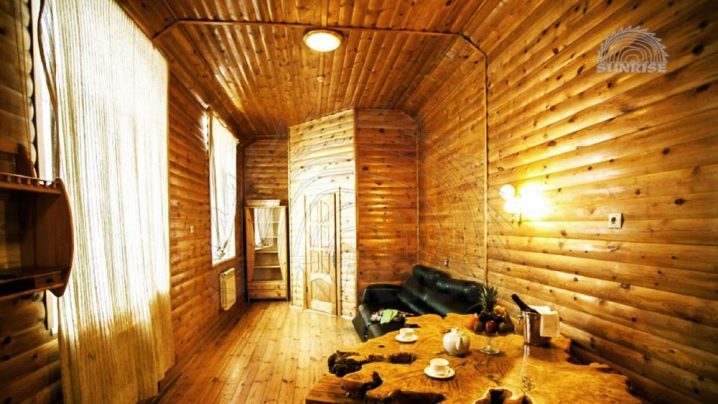

The block house is used for finishing not only walls, but also ceilings.Wide panels with bright natural texture create an imitation of a country house from a log house.

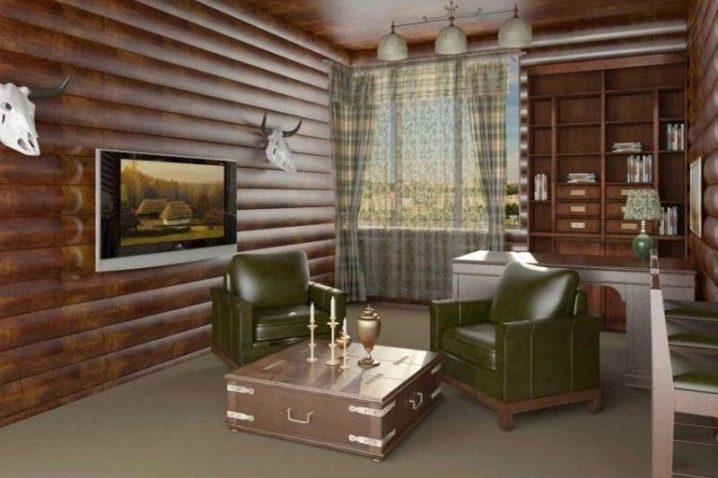

Wood cover can not only create a homely atmosphere. The block house of dark tones perfectly emphasizes the strict interior of the study.

The decoration of the bedroom with wooden panels looks restrained and calm, which contributes to rest and relaxation.

How to decorate the rest room with a block house, see the following video.