We build a house of claydite blocks

When building a house, it is important to choose a quality material that would have not only strength, but also impeccable performance characteristics. To date, keramzite-concrete blocks are very popular with developers. They allow you to quickly cost a building, are affordable and provide rooms with excellent thermal insulation.

Special features

Expanded clay blocks are a versatile building material, which is made from sand, cement and crushed expanded clay. The strength of the blocks depends on the fraction of haydite included in their composition. The larger it is, the less quality the product turns out, since it loses the properties of thermal conductivity and resistance to external influences.

Clay blocks are produced according to the standards of GOST 613399 and are divided into the following groups:

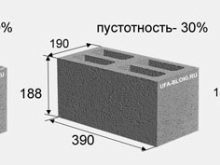

- for the construction of supporting structures that have dimensions of 188 × 190 × 390 mm;

- for the construction of partitions, whose dimensions are 188 × 90 × 390 mm.

In addition, the material may be with the presence of voids, full-bodied, facial and ordinary. Facial blocks, as a rule, are used for structures that do not require additional lining, and ordinary ones need to be decorated with finishing. Hollow products are chosen in cases where it is necessary to reduce the weight of the structure.

Unlike corpulent hollow ones, there are special openings that increase the insulating properties of the material, but the second option has low strength and does not withstand the load. The main feature of such blocks is that they often have inaccurate dimensions, but such deviations are permissible in construction, if the length, height and width of the value diverges from 10 to 20 mm.

Before building a house of claydite-concrete blocks, it is important to choose the right density of the material, because not only the reliability of the whole structure will depend on it, but also acoustic, heat-saving indicators.Typically, the density of blocks ranges from 500 to 1800 kg / m3, and their weight, respectively, can vary from 10 to 23 kg.

Performing construction work with this product is practically no different from building a house of bricks. In order to obtain a warm and stable structure, the thickness of the walls is made at 0.65 m and a waterproofing layer is necessarily applied.

In some cases, reinforcement is also laid around the perimeter of the house, which increases the strength of the structure. For single-storey buildings, lighter blocks with heat insulation are used, and for multi-storey buildings, products with a density of up to 1200 kg / m3 are preferred. An equally important point for houses made of expanded clay blocks is the choice of a reliable foundation, which is deepened by 1.2 meters to protect against uneven precipitation of the soil and the appearance of cracks in the walls.

Advantages and disadvantages

Expanded clay, which is part of the blocks, is a lightweight material that is produced from ecological raw materials without the addition of harmful components, so it is often used for the construction of houses.

The main advantages of the product can also be attributed.

- Low hygroscopicity. Despite the fact that cement is considered to be the main component of expanded clay concrete, the blocks have high resistance to moisture.

- Frost resistance This indicator may be different.Depending on the type of unit, the number of freezing and thawing cycles is from 15 to 200.

- High strength and density. Constructions of expanded clay, as a rule, operate up to 65 years.

- Fireproof.

- Resistance to decay processes, the effects of rodents and insects.

- Low thermal conductivity. Houses from such blocks turn out warm.

- Good vapor permeability. The material "breathes", therefore, provides the structure with an optimal microclimate.

- Ease of construction. All work on the construction of structures can be performed independently, without the help of experts.

- Small weight of the product. Due to this shrinkage is not observed.

- Reasonable price and solution savings. For laying blocks, it is required two times less concrete mix than in the construction of brick buildings.

As for the shortcomings, they are few.

- Construction of structures is carried out on a solid foundation. That the basis was reliable, it is impossible to save on it.

- During the laying of blocks, cold bridges (seams) may form. They need to be embedded and additionally insulated walls.

Projects

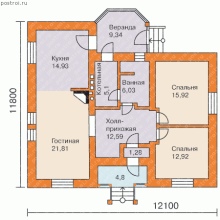

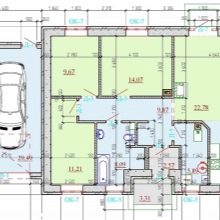

The construction of the house begins with the drafting of the project, for this you first need to think about the layout of the premises and prepare the relevant documentation.First of all, they pay attention to the architectural part and determine the number of floors of the building, draw drawings and sketches of the facade arrangement. Then draws up the foundation scheme, floors and masonry blocks. At this stage, it is also necessary to include in the drawings the conduct of such communications as sewerage, water supply, electrical wiring and gas supply. The design is completed by the calculation of the estimate, which takes into account the cost of all building materials.

One-story houses are considered the most economical, so their projects are very popular. Thanks to the competent planning of the claydite-concrete blocks, you can create a comfortable, cozy and affordable housing. To build such a building does not require special construction equipment, and the cost of the material will be small.

As a rule, single-storey buildings have a total area of up to 81.5 m2, it is quite enough to rationally plan a living space of 60 m2. Typically, such projects include a kitchen-studio, a spacious living room and three bedrooms. This versatile option is well suited for comfortable living of a large family.

One-story houses can also be additionally equipped with a small thermae and a terrace. Inside, wall finishing is recommended to be made of wood or drywall, and for exterior cladding it is best to use plaster. It looks attractive and does not require large expenditures. If financial opportunities allow, then you can opt for a two-story cottage project. Due to the large area, it will be possible to uniquely equip the space, applying modern variants of stylistics. The layout in this case may consist of several bedrooms, a spacious living room, kitchen, bathroom and nursery. In addition, in such a house is easy to allocate space for the library, office and billiard room. The "highlight" of housing will also be a chic pool.

Wooden beams can be used as a material for the floors, but it is best to give preference to reinforced concrete floors, as they are much stronger. As for the base, then for a multi-storey structure, a finely recessed strip foundation is considered the ideal choice; it is inexpensive and reliable in operation.

Interior decoration can be done for every taste, and externally the house is well lined with plaster or sheathed with siding.

Choosing a foundation

Recently, most developers are building houses of expanded clay concrete blocks, as they are characterized by low cost and reliability. In order to improve the performance characteristics of such buildings, it is important to choose the foundation correctly and lay it in a high-quality manner, since the slightest mistake can lead to the draft of the house, as a result, deformation and cracks will appear on the walls.

The base of lightweight aggregate structures must meet the following requirements:

- have high bearing capacity;

- have water resistance;

- provide low heat loss to the building.

Today most often use the following types of the base.

- Ribbon. The choice of the monolithic base is well suited for projects of houses with basement. This type of foundation is laid on flat areas with dense ground. The base must be equipped with heat and waterproofing. In some cases, a precast strip foundation is also made, its structure is similar to monolithic, and the blocks are laid directly on the cement.

- Pile with grillage.It can be installed on plots with any type of soil, as bored piles with a deep grillage are used. Such a foundation is durable, economical and reliable. The only thing that pile foundations are not recommended for the construction of buildings from light blocks.

- Slab. There are no restrictions on the type of soil and weight of the structure. This foundation is reliable, but is expensive and not suitable for building sites with difficult terrain.

- Columnar. It is a combination of columns of brick, stone or concrete. It is usually laid for lightweight structures placed on heaving soils. There are no minuses at the base, as it combines an affordable price and high quality.

Building

It is easy to build a house of expanded clay with your own hands, the main thing is adhere to certain rules in construction work, which include the following steps:

- foundation construction;

- masonry walls of claydite;

- arrangement of the roof;

- warming;

- facing.

Step-by-step instructions will help the beginning masters in this. First of all, the foundation is laid, its technology depends on the composition and structure of the soil,as well as the level of groundwater. After a detailed analysis of the soil, a more suitable type of foundation is selected.

Most often poured tape base. For this, the surface of the working platform is prepared, small vegetation is removed and the uprooting of shrubs or trees is carried out. Then the base is marked with a rope and pegs.

In order for the building to stand on a solid foundation, a trench is being dug, whose depth should exceed the level of soil freezing. The bottom and walls of the trench are carefully leveled and prepared for installation formwork of plywood boards or edged boards. After that, a mixture of sand and rubble is filled up, its thickness is evenly distributed and rammed. It is also necessary to assemble a reinforcing frame; for this, the rods are fastened together by means of knitting wire or welding.

Next is preparing a concrete mix. Solution consumption per 1 m3 is determined depending on the volume of work. The finished composition is poured into a trench so that air bubbles do not appear. The surface is well leveled and covered with plastic wrap to preserve moisture.When the hardening process is completed, the formwork is removed, now you need to put waterproofing and insulation.

The next step will be laying the blocks and forming the box at home. Experts recommend attaching the material to a special adhesive composition. In order to properly perform the laying of the first row, work begins from the corner zone, exercising horizontal control from the inside using a level.

The next row is slightly offset by 1/2 or 1/3 of the thickness of the block. Every 3-4 rows should be reinforced reinforcing mesh.

When the walls are ready, you can proceed to the arrangement of the roof. Before that, a suitable material is selected to cover it. It must be strong, resistant to the influence of the external environment and durable. In addition to the roofing material, a wooden bar with a section of 150 × 150 mm, an edged board, dowel and hardware for fastening will also be required. First of all the crate is prepared, rafters are nailed to it, the material is put. Then we make the house warming. So that the comfort microclimate is constantly maintained in the premises, heat insulation is put both outside and inside the building. For these purposes, mineral wool, foam plastic or cladding panels are best suited.Exterior cladding is carried out depending on personal preferences, the main thing is that the house harmoniously fit into the landscape design of the site.

The cheapest and simplest way is considered to be covering the facade with polystyrene foam blocks, they are made up to 50 cm thick and therefore can warm the building well. The blocks are placed on a special solution and secured with dowels. After that, they install a reinforced mesh and put polymer cement. In this case, finishing can be either a facing tile or decorative plaster.

Excellent proven innovative "ventilated" facades. Such installation work is difficult and expensive. First of all, a vapor barrier in the form of aluminum foil is applied to the base of the walls, then the guides are mounted and mineral wool is fixed to them. External cladding is usually carried out with aluminum panels or siding.

Recommendations

Before you start self-construction of a claydite-concrete house, it is important not only to draw up a project correctly, but also to study the feedback from the owners of such housing.The clay block is an environmentally friendly material, but sometimes during operation it may reveal hidden problems. Therefore, the best blocks to purchase from well-proven manufacturers, providing quality certificates for products. You will receive a guarantee that the material is not dangerous to human health.

During construction it is worth considering the following recommendations of experts.

- After the foundation shrinks, its surface may become curved. To eliminate this, it is necessary to perform a leveling solution, controlling the level of flatness.

- To increase the life of the house will help high-quality waterproofing. Therefore, after the concrete hardens, several layers of roofing material are laid on the foundation, and the mastic is placed between them.

- The clay block (like the foam block) is first laid from the corner, forming the first row. Then they lay the next rows, checking the flatness of the walls.

- If double walls are erected, then two rows of blocks are laid out simultaneously, making a bundle between them from sand-cement mortar.

- When building a two-story building, the walls of the first floor must be reinforced with reinforcing belts.Due to this, the weight loads are evenly distributed to the blocks both from the side of the walls of the second floor and the floors themselves. Such a belt is made of reinforced concrete blocks or bricks. Reinforcement belt must be further warmed.

In the next video you will find a masonry wall of claydite-concrete blocks.