Prefab houses and CIP panels: which designs are better?

The main question that arises before anyone who decided to build their own house is what it will be. First of all, the house should be cozy and warm. Recently there has been a clear increase in demand for frame houses and built of CIP panels. These are two radically different construction technologies. It is necessary to carefully examine all the nuances of each of them before proceeding to the construction of the house of your dreams.

Erection technology

Frame structure

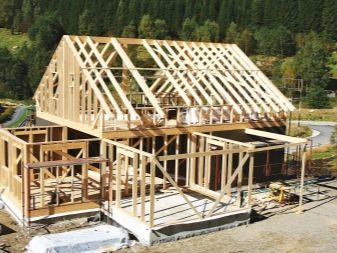

There is another name for such a house - frame-frame. This construction technology was developed in Canada and already belongs to the category of classic. The first step in the construction of the foundation is poured. Most often in this technology the column base is used, as it is ideally suited for the frame house.As soon as the foundation is ready, the construction of the framework of the future dwelling begins.

At the base of the frame is used timber of different thickness depending on the places of the intended load. After the construction of the frame should install it on the foundation, plating material selected for construction and insulation.

Building of sandwich panels

SIP panel (sandwich panel) is two oriented strand boards, between which there is a layer of insulation (foam plastic, expanded polystyrene). The house of SIP panels is built on the basis of a frame-shield (frame-panel) technology. A classic example of the construction of the house of CIP panels can serve as the assembly of the designer. It is literally assembled from panels by connecting them together according to the thorn-groove principle. The foundation in such buildings is predominantly tape.

If we look at it in comparison, the main difference between houses from CIP panels is cheaper and this is their main advantage. If you compare the reviews, you can see that this material is much more positive.

Materials used in construction

The construction of any building begins with the pouring of the foundation.This is the basis of the house, so the material for it should be of the highest quality and durable. Traditionally, the foundation requires the following materials:

- foundation blocks;

- rubble or gravel;

- cement;

- construction fittings;

- knitting wire;

- sand.

If the area where it is planned to carry out construction is marshy or the groundwater is at a level above the average, then the foundation for the frame house should be laid on piles. In rare cases, when the soil at the site of work is particularly unstable, a reinforced concrete slab is placed at the base of the foundation. If desired, in the basement of the house you can arrange the ground floor. In this case, additional materials will be required. Such as waterproofing, for example.

The frame may be wooden, metal or reinforced concrete. For wooden frame used:

- board;

- solid timber;

- glued laminated timber;

- wooden I-beam (wood + OSB + wood).

The metal frame is constructed from a metal profile. Here the profile itself may be different:

- galvanized;

- colored.

The strength of the frame is also affected by the thickness of the profile used.

Reinforced concrete (monolithic) frame is the most durable, but also the most time consuming and costly. For its construction are necessary:

- iron fittings;

- concrete.

For the erection of walls with frame-frame technology, additional laying of thermal insulation, windscreen, wall paneling of fibreboard-canvas and exterior siding is required.

When building a house of CIP panels, the need for such a number of building materials disappears. SIP-panel is manufactured at the factory. Already in the panel itself is laid and a heat insulator, and trim. The maximum of material that is needed for building a house of CIP panels falls on the foundation casting.

Construction speed

If we talk about the timing of the construction of frame houses and houses from CIP panels, then the latter win. The construction of the frame and its subsequent trimming is a rather lengthy process, it takes from 5 weeks and longer against the minimum two-week erection of the structure from CIP panels. The construction speed is often affected by the foundation, which can be created for a house from CIP panels in just a couple of days.

If the construction of a frame house can not do without all sorts of fit,trimming and leveling timber, then any structure of CIP panels can literally be ordered at the factory according to the required size. After the panels are ready, simply bring them to the construction site and assemble. With all the necessary machinery and equipment, this is a fairly quick process.

Cost of

Price is an important argument that can outweigh the scales in the direction of construction, and in favor of abandoning it. The pricing of the house is directly dependent on the materials from which it will be built.

The structure of the metal profile will definitely cost more. The difference with a wooden frame can be up to 30%. Plus to the price of the frame house is an additional use of materials for a covering of the house, heaters and a siding.

In addition to the cost of materials, the total cost of building a frame house must include the cost of services of various kinds of specialists, without which it can hardly be dispensed with. The construction of durable housing frame-frame technology requires compliance with many technical nuances that ordinary builders may be unfamiliar with.

The frame house requires a fairly expensive secondary finishing. This is a thermal film, supermembrane, panel materials. The construction of CIP panels practically does not require any additional materials, except for those that are already laid in the basis of the panels themselves. Accordingly, this makes the price of such houses more attractive.

However, the money that can be saved on the purchase of materials, will go to pay for hired builders. It is impossible to build a building from SIP panels without the help of equipment and a brigade of workers.

Another moment affecting pricing is the transportation of CIP panels. In the case of a frame house, all work is carried out directly on the site of construction. CIP panels must be delivered from their place of production to the construction site. Given the considerable weight and the number of panels, special equipment is needed for transportation, the cost of which services need to be added to the total cost of construction.

Strength

Speaking about this indicator, you need to rely on two factors: the service life and the ability of the future building to withstand mechanical loads. In the frame house all the main burden falls on the floor beams.Until the tree itself decays, the entire foundation of the building will have sufficient strength and durability. Here the main role is played by the choice of wood for the frame.

The disadvantage is that all the basic fastenings fall on nails, screws and wood screws. This greatly reduces the rigidity of the frame.

SIP-panels, even if they are installed without any frame, are firmly coupled with each other by grooves. The panels themselves, when tested by a truck passing through the panels, demonstrate excellent strength.

The approximate strand board, which is the basis of any CIP panel, is not in itself capable of enduring the slightest mechanical damage. However, when reinforcing two plates with an “interlayer” of a special material, the panel is able to withstand a vertical load of 10 tons per meter. With a horizontal load, it is on the order of a ton per 1 square meter.

The service life of a frame house is 25 years, after which it may be necessary to replace the main struts of the frame. Again, with the right choice of high-quality wood and compliance with the technology of the system, such a structure can be in operation much longer.According to official standards, the service life of a frame house is 75 years.

The service life of CIP panels depends on the material of manufacture. Thus, panels using polystyrene will last 40 years, and magnesite plates can extend this period to 100 years.

Design features

Design and layout of the frame house can be any. Another important point: it can be rebuilt at any time. To do this, you only need to remove the casing to replace some parts in it. The frame in this case will remain intact.

What can be said about the house of CIP panels, which can not be rebuilt without not dismantling it to the ground. Then it will no longer be about redevelopment, but about the full-fledged construction of new housing. In addition, due to the fact that all the panels for the future house are made in advance, there are not so many options for planning houses from CIP panels.

Environmental friendliness

For those who are concerned about the environmental friendliness of their homes, the option of a frame house is preferred. SIP-panels contain a chemical component in the form of a "layer" between the plates. From the type of filler panels, their health hazards may vary.Houses made of CIP panels do not stand up to any environmental competition with buildings made of pure wood.

In the event of a fire, the chemical component of the panels will make itself felt in the form of combustion products that are dangerous to human life and health.

Heat and sound insulation

Houses from CIP panels are often called “thermos” because of their features in terms of heat storage. They have an amazing ability to keep warm inside, but they practically do not let the air through. Such a house requires the installation of a good ventilation system.

Any frame house can be made almost perfect in terms of heat storage. It is enough to spend time and money on additional high-quality lining of it with insulating material.

Both the frame house, and the house from the VULTURE panels do not differ in good sound insulation. This is a common problem for buildings of this type.

Ensure a sufficient level of noise insulation is possible only with the help of good plating with special materials.

To learn how to build a house correctly from CIP panels, see the following video.