Foundation plate reinforcement: calculation and installation technology

The construction of any building involves the formation of the foundation, which will take the entire load on themselves. Its durability and strength depend on this part of the house. There are several types of bases, among which special attention should be paid to monolithic slabs. They are used on persistent soils, where there are no significant fluctuations in the level. An important element of this design is the fittings, allowing to increase the strength of the monolith.

Special features

Monolithic slabs are constructions of high-quality concrete. The material is highly durable. The disadvantage of the base plate is its low plasticity.Concrete structures quickly crack under high loads, which can lead to the formation of cracks and subsidence of the foundation.

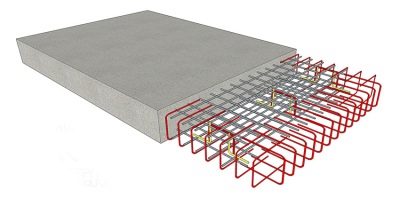

The solution to this problem is the reinforcement of the slab with the help of various types of steel wire. Technically, this process involves the formation of a metal frame within the foundation itself.

All such operations are carried out on the basis of special SNiP, which describes the basic technology of reinforcement.

The presence of steel frames allows you to increase the plasticity of the plate, since high loads are already perceived as metal. Reinforcement allows you to solve several important problems:

- The strength of the material increases, which can already perceive high mechanical loads.

- The risk of shrinkage of the structure is reduced, and the likelihood of cracks occurring on relatively unstable soils is minimized.

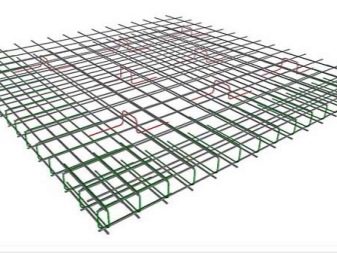

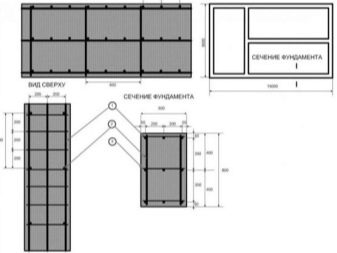

It should be noted that all the technical characteristics of such processes are regulated by special standards. These documents indicate the parameters of monolithic structures and the basic rules for their installation.Reinforcing element for such plates is a metal mesh, which is formed by hand. Depending on the thickness of the monolith, the reinforcement may be arranged in one or two rows with a certain distance between the layers.

It is important to correctly calculate all these specifications in order to obtain a reliable frame.

Scheme

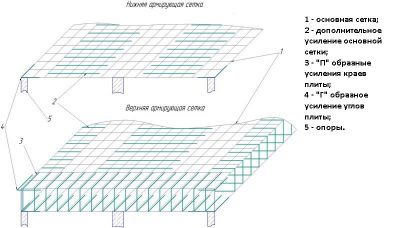

Reinforcement plates is not a difficult process. But there are several important rules that must be followed in this procedure. Thus, the installation of reinforcement can be done in one or several layers. It is desirable to use single-layer structures for slab foundations with a thickness of up to 15 cm. If this value is greater, then it is recommended to use a multi-row arrangement of valves.

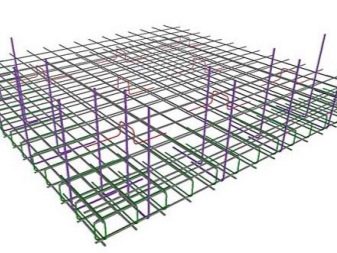

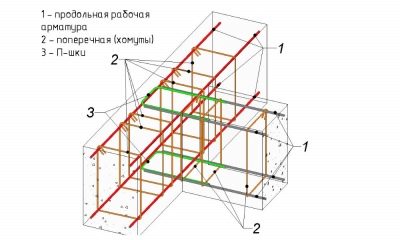

Between themselves, the reinforcing layers are connected with the help of vertical supports, which do not allow the upper row to fall.

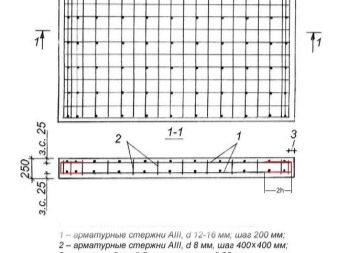

The basic width of the slab should be formed from evenly spaced cells. The step between the reinforcing wire both in the transverse and in the longitudinal direction is chosen depending on the thickness of the monolith and the load on it. For wooden houses, the wire can be knit with each other at a distance of 20–30 cm, forming square cells.The optimal step for brick buildings is a distance of 20 cm.

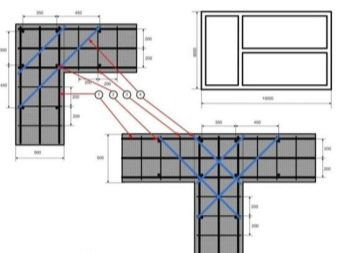

If the design is relatively light, then such a value can be increased to 40 cm. The ends of each plate, according to standard standards, should be reinforced with U-shaped reinforcement. Its length should be equal to 2 thickness of the monolithic plate itself.

This factor should be considered when designing structures and selecting reinforcing elements.

Supporting frames (vertical rods) are installed in increments that are similar to the parameters of the location of the reinforcement in the grid. But sometimes this value can double. But they use it for foundations that will not succumb to very heavy loads.

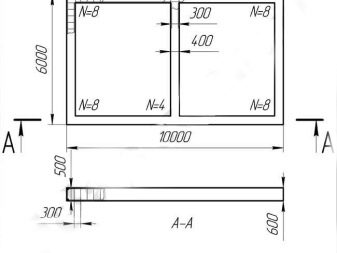

Punching zones are formed using a grid with reduced pitch. These segments represent the part of the slab on which the building frame (bearing walls) will later be located. If the main zone was laid using squares with a side of 20 cm, then in this place the step should be approximately 10 cm in both directions.

When arranging the zone of conjugation of the foundation and monolithic walls, so-called outlets should be formed. They are vertical pins of reinforcement, which with the help of knitting are connected to the main reinforcing frame. This form allows you to significantly increase the strength and provide high-quality connection of the support with vertical elements. The fittings during assembly of the outlets should be folded in the shape of a letter G. In this case, the horizontal part should have a length equal to 2 heights of the foundation.

Another feature of the formation of reinforcing cages is the technology of connecting the wire. This can be done in several basic ways:

- Welding. Long process which is possible only for steel fittings. It is used for small monolithic slabs with a relatively minimal amount of work. An alternative option is the use of ready-made welded structures made in production. This allows you to significantly speed up the process of forming the frame. The disadvantage of this connection is that the output is a rigid structure.

- Mating The reinforcement is connected with the help of thin steel wire (diameter 2–3 mm). The twisting is performed with special devices, allowing a little to speed up the process.This method is quite time-consuming and lengthy. But at the same time, the reinforcement is not rigidly connected with each other, which allows it to adapt to certain fluctuations or loads.

The technology of reinforcement of the foundation can be described by the following sequential actions:

- Preparation of the base. Monolithic slabs are located on a kind of pillow, which is formed from rubble and sand. It is important to get a solid and even base. Sometimes, before pouring concrete into the soil, special waterproofing materials are laid to prevent the penetration of moisture to the concrete from the ground.

- The formation of the lower reinforcing layer. Armature consistently placed initially in the longitudinal and then in the transverse direction. Bind it with wire, forming square cells. So that the metal does not protrude from the concrete after it is poured, you need to slightly raise the resulting structure. To do this, under it enclose small supports (chairs) made of metal, the height of which is selected depending on the height of the monolithic plate (2-3 cm). It is desirable that these elements were made of metal.Thus, directly under the grid, a space is formed, which is filled with concrete and closes the metal.

- Arrangement of vertical supports. They are made of the same fittings as the mesh itself. The wire is bent in such a way as to obtain a frame on which the top row can lean.

- Formation of the upper layer. The grid is constructed in the same way as it was done for the bottom row. It also uses the same cell size. Attach the design to the vertical supports one of the known methods.

- Fill When the reinforcing frame is ready, it is poured with concrete. A protective layer is also formed above and laterally above the mesh. It is important that the metal does not show through the material after the foundation solidifies.

How to calculate?

One of the important elements is the calculation of technical characteristics of reinforcement bars. In most cases, the grid step is 20 cm. Therefore, special attention should be paid to the calculation of other parameters. The procedure begins with determining the diameter of the reinforcement. This process consists of such sequential steps:

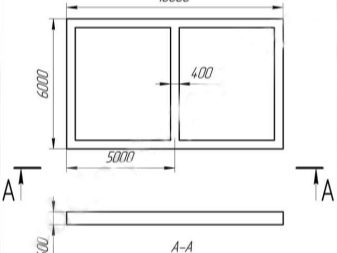

- The first step is to determine the cross section of the foundation. It is calculated for each side of the plate.To do this, you need to multiply the thickness of the future foundation by the length. For example, for a 6 x 6 x 0.2 m plate, this figure will be 6 x 0.2 = 1.2 m2.

- After that, you need to calculate the minimum area of reinforcement, which should be used for a specific series. It is 0.3 percent of the cross section (0.3 x 1.2 = 0.0036 m2 or 36 cm2). This factor should be used when calculating each side. To calculate a similar value for a single row, simply divide the resulting area in half (18 cm2).

- Knowing the total area, you can count the number of rebars that should be used for one row. Please note that this applies only to the cross section and does not take into account the amount of wire that is laid in the longitudinal direction. To find out the number of rods, you should calculate the area of one. Then the total area divided by the value obtained. For 18 cm2, 16 elements with a diameter of 12 mm or 12 elements with a diameter of 14 mm are used. You can find out these parameters in special tables.

To simplify such calculation procedures, a drawing should be drawn up. Another step is to count the amount of reinforcement to be purchased for the foundation. To calculate it is quite simple in just a few steps:

- First you need to know the length of each row. This is calculated in both directions if the foundation has a rectangular shape. Please note that the length must be 2–3 cm less on each side in order for the foundation to close the metal.

- When you know the length, you can calculate the number of rods in one row. To do this, divide the resulting value into a lattice step and round up the resulting number.

- To find out the total footage, you should carry out the operations described earlier for each row and add the result together.

Tips

The formation of a monolithic foundation can be carried out in various ways. To get a quality design, you should follow these simple tips:

- Armature should be placed in the thickness of the concrete to prevent the rapid development of metal corrosion. Therefore, experts recommend to “heat” the wire on each side of the plate to a depth of 2–5 cm, depending on the thickness of the plate.

- Only reinforcement of class A400 should be used to reinforce foundations. Its surface is covered with a special herringbone, which increases the bond with the concrete after solidification.Do not use products of lower class, as they are not able to provide the desired strength of the structure.

- When connecting the wire should be laid with an overlap of about 25 cm. This will create a more rigid and reliable frame.

The reinforced monolithic foundation is the perfect foundation for many types of buildings. When completing its construction, follow standard recommendations and you will get a durable and reliable construction.

In more detail about the reinforcement of the base plate will tell the following video.