Foundation beams: features and their scope

The building begins with a foundation. The earth “plays”, therefore the operational capabilities of the object depend on the strength of the base. Foundation beams are widespread due to their fundamental characteristics.

What it is?

The foundation beams are a reinforced concrete structure that serves as the foundation of the building. They perform a dual function:

- are bearing elements in non-monolithic interior and exterior walls;

- separating the material of the walls from the ground, performing the function of waterproofing protection.

A potential buyer will appreciate the frost resistance and heat resistance of structures, as they make them a durable material that will serve for many years.The ability of foundation beams to withstand large pressure walls allows them to be used in the construction of basements and foundations of houses.

Purpose

The classic use of reinforced concrete beams (or randbolok) is carried out in the construction of industrial, agricultural facilities and public buildings. They serve as a support for external and internal walls of buildings. With modern technology at the design stage of the building project, it is possible to use foundation beams for the construction of residential premises. The use of randballs is an alternative to the monolithic construction of the foundation; it is a composite technology when laying the foundation of a building.

Beams are intended for:

- self-supporting block and panel type walls;

- self-supporting brick walls;

- walls with hinged panels;

- solid walls;

- walls with door and window openings.

By destination in the construction of FB are divided into four groups:

- wall mounted, they are mounted near the outer walls;

- connected, installed between the pillars that form the layout of the building;

- Ordinary beams are used to bond wall and coherent beams;

- sanitary-technical ribbed products intended for sanitary-technical needs.

Laying a stacked type foundation for the construction of large objects is the optimal area for the application of foundation beams. But it is also effective to use them as a grillage for a pile or column base of frame structures, since they make it possible to fasten the entire frame of a building.

The advantages of these reinforced concrete structures compared with the monolithic technology are:

- reduction of construction time;

- facilitation of underground communications inside the building.

Today, due to the special characteristics, the use of foundation structures plays an important role. Their cost, according to calculations, is about 2.5% of the total cost of the building.

The widespread use of prefabricated foundation construction is a simple and inexpensive method of laying compared to a strip foundation. Structures must be securely fastened. Classically used stakanny type of foundation, when the individual elements are based on the steps on the side. If the height of the step and the beams do not match, then the installation of brick or concrete columns is provided for this.

When using the column foundations it is admissible to make support from above. The bollards are called pillows. With a large base of the building, it is possible to create special niches in its upper part, into which standard beams are mounted. Models of trimmed beams are used in separate cells of buildings and attached to a temperature transverse seam.

In the construction of frame structures, the use of foundation beams is advisable for the installation of external walls. Products are stacked on the edge of the foundation, covered with a solution of concrete. In order to prevent excessive moisture, as a rule, a solution of sand and cement is applied over the reinforced concrete structures.

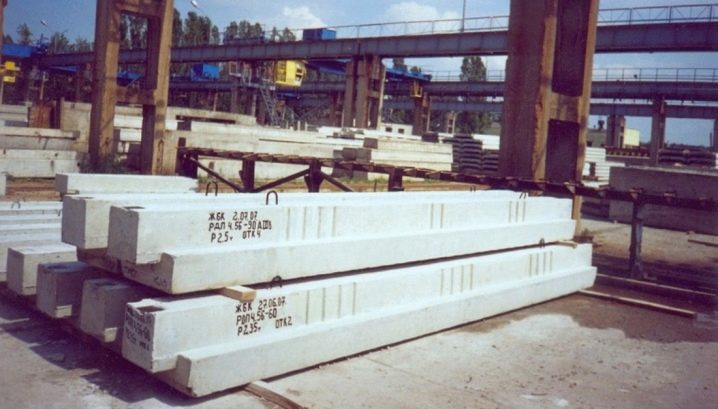

Installation of foundation structures is carried out only with the use of lifting equipment, as their weight ranges from 800 kg to 2230 kg. According to the standards of GOST, beams are made with holes provided for lifting and their installation. Thus, using slinging holes or special factory mounting hinges and special gripping devices, the beam is attached to the crane winch and placed on the designated place.Beams are mounted on poles or piles, in exceptional cases - on sand and gravel bedding.

The weight of the product does not require additional mounts with a support. However, it is recommended to observe the minimum amount of bearing, not less than 250-300 mm. For further work, as well as to prevent damage to the walls, it is desirable to provide a layer of waterproofing materials (roofing material, linokrom, waterproofing). Thus, foundation beams are a material of high quality and adequate in characteristics and price.

Regulatory requirements

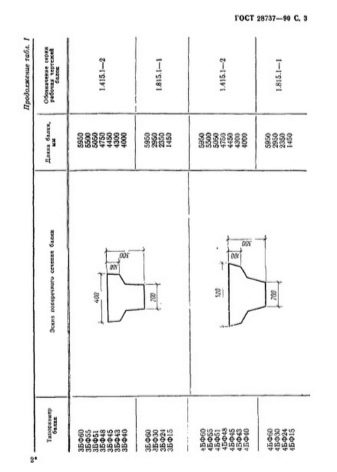

The structures are manufactured in accordance with the technical specifications of GOST 28737-90, introduced by the USSR State Building Committee in 1991. Time and practice have proven the quality of this product. According to GOST Soviet times, the manufacture of foundation structures is regulated in terms of the size of structures, their cross-sectional shapes, markings, materials, requirements and acceptance procedures, quality control methods, and storage and transportation conditions.

When ordering and purchasing foundation beams, you need to know the required design characteristics of the product.

Technical requirements: cross-sectional view, size, length and designation of a series of working drawings of beams - can be found in Table No. 1 GOST. The raw material for the manufacture of beams is heavy concrete. Product length, reinforcement type and load calculation data influence the choice of concrete grade. Usually beams are made from concrete grades M200-400. Product specifications allow you to optimally ensure the load from the walls.

Regarding the reinforcement GOST allows:

- prestressed reinforcement for structures longer than 6 m;

- for beams up to 6 m prestressed reinforcement at the request of the manufacturer.

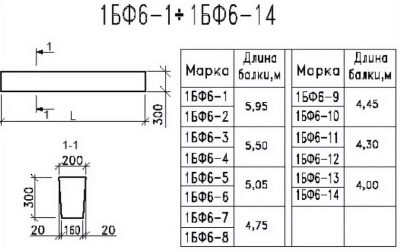

Traditionally, plants all beams are produced with pre-stressed reinforcement of steel grade A-III. Having determined the dimensions and cross-section of the product, it is necessary to indicate the marking correctly, especially on the basement variants. It consists of alphanumeric groups separated by a hyphen. Usually marking consists of 10-12 characters.

- In the first group of signs indicates the size of the beam. The first digit indicates the type of section, it can vary from 1 to 6. The letter set indicates the type of beam. The numbers after the letters indicate the length in decimeters, rounded to the nearest whole number.

- The second group of digits indicates the sequence number coming from the carrying capacity. This is followed by information on the class of prestressing reinforcement (only for stressed beams).

- The third group indicates additional characteristics. For example, in the case of increased corrosion resistance at the end of the marking, the “H” index or design features of the beams (mounting hinges or other embedded products) are placed.

An example of the symbol (mark) of the beam indicating the bearing capacity and data of the reinforcement: 2БФ60-3AIV.

An example of the symbol with the indication of additional characteristics: replacement of slinging holes with mounting loops, production of normal permeability (H) from concrete and intended for use in conditions of exposure to a slightly aggressive medium: 4БФ48-4АТVCK-На. Three types of products define a set of letters:

- solid foundation beams (FBS);

- solid foundation beams with a cutout for laying jumpers or skipping engineering structures (FBV);

- hollow core beams (FBP).

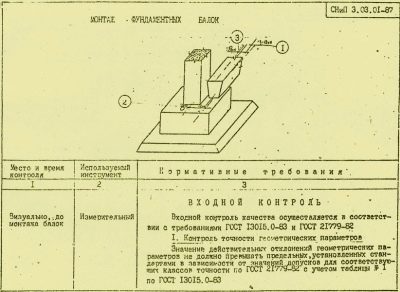

The quality control of the foundation beams requires verification:

- concrete compression class;

- release strength of concrete;

- availability and correlation of reinforcement and embedded products;

- accuracy of geometric indicators;

- the thickness of the protective layer of concrete to reinforcement;

- width of the shrinkage cracks.

In the technical passport of the purchased batch of randballs should be indicated:

- grade of concrete strength;

- release strength of concrete;

- prestressed reinforcement class;

- brand of concrete for frost resistance and water permeability.

The transportation rules for FB provide transportation in stacks. A stack height of up to 2.5 m is allowed, the distance between the stacks is no more than 40-50 cm. A prerequisite is the presence of gaskets between the beams and linings between the stacks. This is especially true for the I-model.

Kinds

The fundamental model is a long heavy concrete pile or column. Beams depending on the width of the surface of the cross section are divided into types:

- for building walls with column spacing up to 6 m (1BF-4BF);

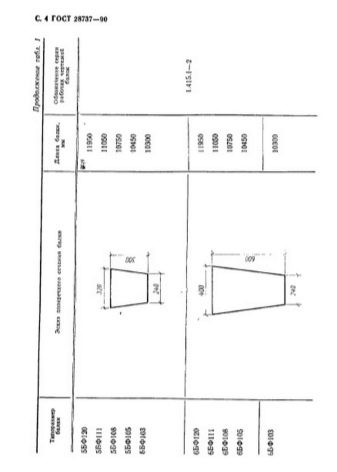

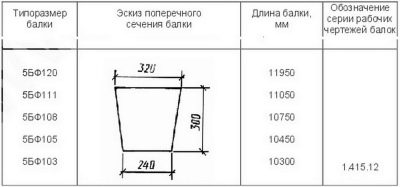

- for building walls with a pitch of 12 mm (5BF-6BF).

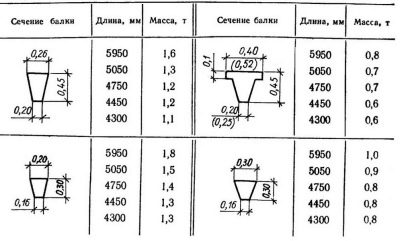

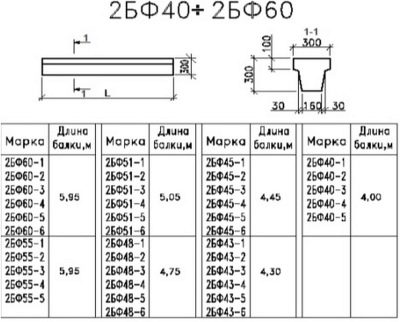

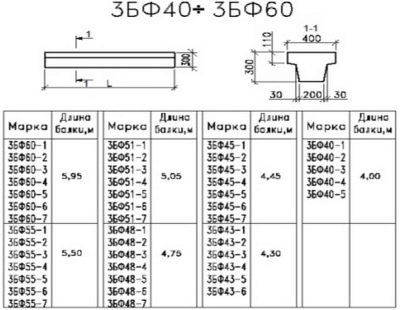

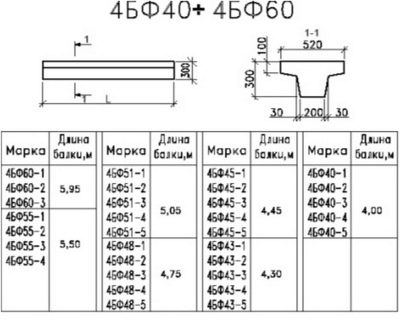

Usually the beam on top has a flat area of a certain size: from 20 to 40 cm wide. The size of the site depends on the types of wall material. The length of the product can reach 6 meters, but not less than 1 m 45 cm. In models 5 BF and 6 BF, the length is from 10.3 to 11.95 m.The height of the beams is 300 mm, except for 6BF - 600 mm. Side of the beam has a T-shaped or truncated cone shape. This form reduces the perceived load.

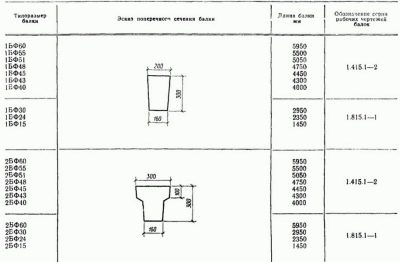

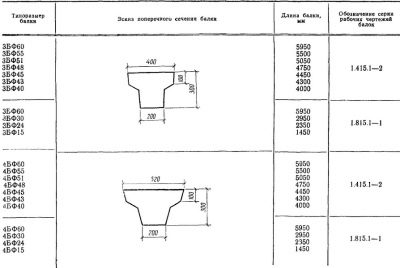

Beams differ by type of sections:

- trapezoid with the bottom edge of 160 mm and the top 200 mm (1 BF);

- T-section with base 160 mm, upper part 300 mm (2BF);

- T-section with supporting part, lower part 200 mm, upper - 40 mm (3BF);

- T-section with base 200 mm, upper part - 520 mm (4BF);

- trapezoidal with a lower edge of 240 mm, upper - 320 mm (5BF);

- trapezoidal with a lower part of 240 mm, the top - 400 mm (6BF).

Indicators allow deviations: in width up to 6 mm, in height up to 8 mm. The following types of foundation beams are used in the construction of residential and industrial buildings:

- 1FB - series 1.015.1 - 1.95;

- FB - series 1.415 - 1. vol. one;

- 1FB - 1.815.1 series - 1;

- 2BF - series 1.015.1 - 1.95;

- 2BF - series 1.815.1 - 1;

- 3BF - series 1.015.1 - 1.95;

- 3BF - series 1.815 - 1;

- 4BF - series 1.015.1-1.95;

- 4BF - series 1.815 - 1;

- 1BF - series 1.415.1 - 2.1 (without pre-stressed reinforcement);

- 2BF - series 1.415.1 - 2.1 (prestressed reinforcement);

- 3BF - series 1.415.1 - 2.1 (prestressed reinforcement);

- 4BF - series 1.415.1 -2.1 (pre-stressed reinforcement);

- BF - RS 1251 - 93 No. 14 –TO.

The length of the beam depends on the distance between the individual walls.When calculating the need to remember about the stock on the bearing from both sides. The dimensions of the section come from the calculation of the load on the beam. Many firms perform calculations for individual orders. But also experts will help you choose the brand of foundation beams, taking into account the engineering and geographical conditions on construction sites.

Modern technologies allow the use of foundation beams under walls with tape glazing, with a device along the entire length of the brick base of the beam up to 2.4 m. Traditionally, when there is a brickwork in the area of the basement and walls, foundation beams are required.

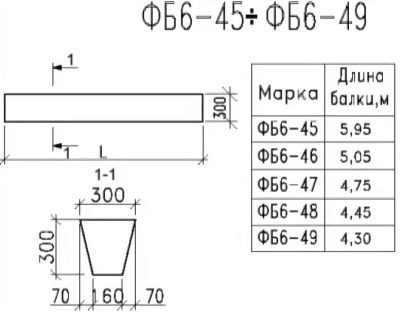

Dimensions and weight

Separate series of foundation beams have their own standard sizes. They depend on the established standards for the dimensions of beams approved by GOST 28737 - 90 to 35 m. Characteristics of beams of type 1BF:

- dimensions of the section 200x160x300 mm (upper edge, lower edge, height of the model);

- model length - 10 variants of sizes from 1.45 to 6 meters are offered.

Characteristics of type 2BF beams:

- dimensions of the section 300x160x300 mm. The thickness of the upper crossbar T-bar 10 cm;

- model length - 11 sizes from 1.45 to 6 meters are offered.

Characteristics of 3BF type beams:

- dimensions of the section 400x200x300 mm. The thickness of the upper crossbar T-bar 10 cm;

- model length - 11 sizes from 1.45 to 6 meters are offered.

Type 4BF specifications:

- dimensions of the section 520x200x300 mm. The thickness of the upper crossbar T-bar 10 cm;

- model length - 11 sizes from 1.45 to 6 meters are offered.

5BF type specifications:

- dimensions of the section 400x240x600 mm;

- model length - 5 sizes from 10.3 to 12 meters are offered.

Characteristics of type 6BF:

- dimensions of the section 400x240x600 mm;

- model length - 5 sizes from 10.3 to 12 meters are offered.

According to the norms of GOST 28737-90, deviations from the specified dimensions are allowed: no more than 12 mm in linear parameters and not more than 20 mm along the length of the beam. Millimeters of deviations are inevitable, since the process of shrinkage during drying is uncontrolled.

Tips

Since the composite technology was developed for mass construction, its use in the construction of private houses has two nuances:

- the use of models of slats manufactured according to GOST standards, it is desirable to initially take into account in the project atypical objects of individual construction;

- the large size and weight of the structures increases the cost of the construction of the building by attracting lifting equipment.

Therefore, when calculating the construction calculations, calculate these nuances. For difficulties in attracting special equipment and labor, use the construction of the grillage in a monolithic version.

- When choosing a model of beams, consider the bearing capacity of the elements, that is, the maximum load of the structural solution of the walls. The bearing capacity of the beam is determined by the author of the project of the building being constructed. This indicator can be specified at the factory or according to special tables for a specific series.

- Pay attention to the fact that the beams that perform the bearing functions should not have cracks, multiple shells, flows and chips.

For information on how to select and install foundation beams, see the following video.