Concrete foundation for the house: types and features of manufacturing

The foundation is the most important part of any building, whether it be a residential high-rise or a large plant, on which the safety of the whole building depends. There are many materials from which support structures of various types are built. Such factors as structure designation, terrain relief, soil composition, weather conditions and much more can affect the choice of the correct foundation. One of the most reliable and durable materials for the construction of such a support is concrete.

Description

The concrete foundation is a self-hardening mixture of a binder, which is cement, gypsum hydrosilicate and other materials.Additionally, it consists of gravel and sand in the required proportions, as well as water, which allows you to turn the dry mixture into a thick solution to fill the space between the fine particles with the binder. Compared to other bases, a concrete foundation has such advantages as:

- uniform shrinkage, eliminating cracks and deformation of the entire structure;

- concrete (and especially reinforced concrete) has the longest service life compared to other materials;

- availability and cheapness of material and works;

- The unique properties of the material, which can be changed directly in the process of work, make it possible to realize even complex architectural ideas.

How does it work?

As with any design or structure, the design of the concrete foundation must be based on certain building codes (SNiP 3.02.01-87). They determine exactly how and in what proportions various mixtures are prepared and how to stack them.

- Sand. For high-quality concrete, grains of sand should be 1-3 mm in size and not contain a large amount of impurities of silt or clay. The permissible percentage of particles in the sand is not more than 5%.

- Gravel. The size of the stones should not exceed 8 cm, they also should not contain a large amount of impurities. Instead of gravel, you can use crushed stone that meets the same requirements.

- Cement. There are several types of cement that can be used to prepare a concrete mix - it is pozzolan cement, slag Portland cement, portland cement. The latter is most often used in the construction of the foundation and is the most appropriate. In addition, each type of cement has a marking (300, 400, 500), which shows the compressive strength in kg / cm².

The grade of cement should always be 1.5–2 times higher than the grade of concrete, which is necessary for different structures depending on their weight. So, M300 and M350 concrete will be suitable for a private two-story house, M250 for wooden cottages, and M200 concrete for garage doors or high fence.

The ideal proportion for making concrete is the ratio of cement, sand and gravel in a ratio of 1: 3: 5. Water is added in such quantity in what it is necessary for receiving this or that brand of concrete and is specified in various regulatory documents.

What happens?

Although the main foundation material is concrete, by its structural features, it is divided into several types.

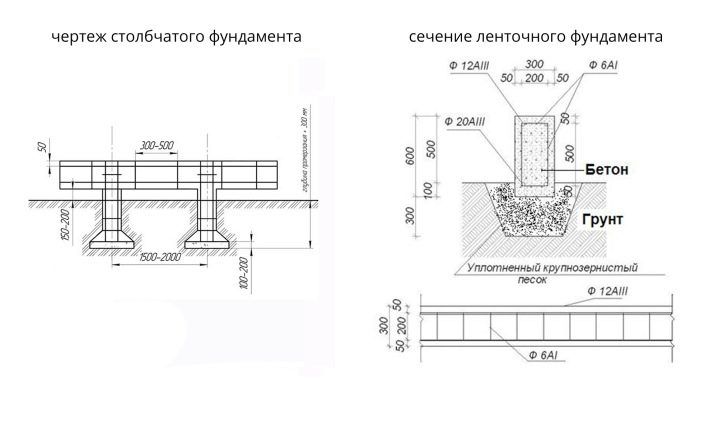

- Pillar foundation is a concrete straight or screw piles, which are placed in the ground with the help of specially designed for this technique. The biggest drawback of this type is the impossibility of the device basement in the building, as well as the need for additional insulation.

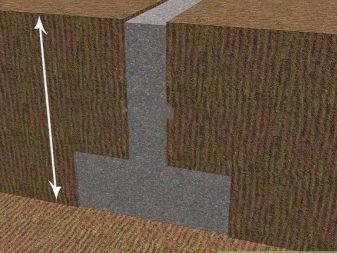

- Strip foundation - This is a continuous line of frozen concrete, located under all external and internal bearing walls. With high-quality heat and waterproofing such a foundation allows you to arrange a basement in the building. It is a strip foundation that is most often constructed with your own hands, since it does not require expensive equipment and high skills.

In addition, the foundation of concrete is divided into the following types:

- butobetonny - the solution layer is covered with a durable rubble stone;

- foam concrete - this foundation is assembled on site from imported foam blocks;

- reinforced concrete (monolithic) - welded reinforcement structure is placed in dug recesses and is poured on top with concrete solution.

How to do?

It is not necessary to buy ready-made concrete or pay for the services of a concrete mixing machine, the solution is easy to prepare at home. The main thing is to follow the resulting calculations and proportions as precisely as possible, to try to keep the process clean. Since the ribbon concrete foundation is being built practically under all country houses, one should dwell on the process of its construction in more detail.

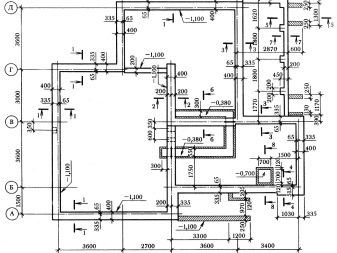

Blueprints

Before proceeding with the calculations, it is necessary to collect all the permits from the local authorities so that no further misunderstandings arise. After receiving all the papers, it is necessary to draw up a general plan of the foundation, the quality of the whole work depends on the accuracy and detail of which. The drawing itself should be created on the basis of calculations of the following indicators:

- type of soil on the site - its composition, density, moisture content, etc. are taken into account;

- degree of load increased during operation (objects and people who will be inside the finished structure, as well as changing weather conditions and precipitation);

- weight of the structure itself. The average weight of various structures of a house can be obtained from various reference books and standards, and their volume and area can be obtained by multiplying the length, height and width of one structural element.

Manufacturing process

Any construction begins with site preparation — all rubbish and grass are removed, the top layer of sod is removed. According to the drawn up drawings with the help of stakes and a rope, the location of the foundation is outlined, and a trench is dug along the indicated boundaries, if the basement is not planned, or a foundation pit, if the basement is assumed. The trench is digging under the inner carriers and all the outer walls of the future house.

After digging the trench, you can proceed to the construction of the formwork when it is needed. It can be built either from any remnants of the boards, or it can be purchased ready-made collapsible or non-demountable in a specialized store.

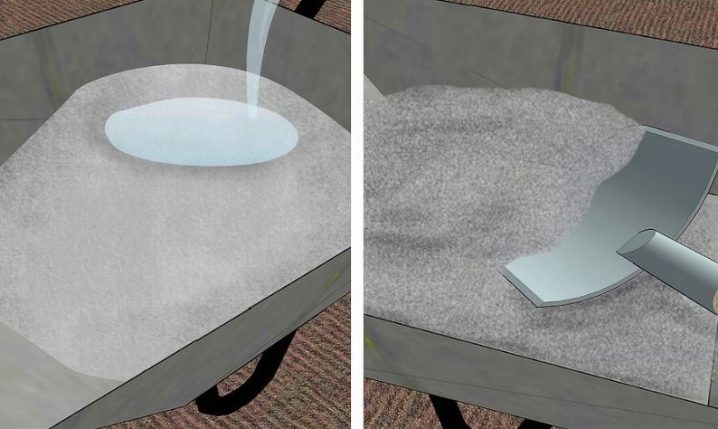

Waterproofing is applied or laid on the surface of the installed formwork, which protects the foundation from the effects of sedimentary and groundwater. It is best to combine both roll and abrasive waterproofing.

A special frame is made of reinforcing bars and placed inside the formwork on brick fragments.It is possible to fasten a steel pipe with others either by simple welding or by “connecting” to each other. The first option is less reliable, as welding reduces the strength of the entire structure. After installing the fittings, you can pour a well-mixed cement mortar. P

When preparing the solution with your own hands, it is impossible to do with the forces of one person, since it is necessary to immediately prepare a large amount of the mixture. It is best to use a special mixer or buy ready-made mix.

Flooded, but unconsolidated solution should be removed from air bubbles trapped inside, using a regular stick to “poke through” the mixture, tapping the formwork outside, or using a special construction vibrator.

After all the work done, it remains only to follow the freezing of the laid foundation. Concrete should be consistently and evenly harden. In hot weather, its surface is moistened with a small amount of water to prevent the surface from cracking, and in the rain the solution is covered with a film in order to prevent excess moisture. Properly frozen mixture quickly gains strength and becomes very reliable.

Any foundation must stand at least a month before the construction of the house itself, as it settles and can be deformed.

On top of the finished foundation after its shrinkage, it is already possible to make installation of load-bearing walls and special concrete posts, on which logs can be fixed under the wooden floor of the first floor and further finished.

Additional processing

To protect the finished foundation from the effects of various aggressive media and the effects of low temperatures during the period of winter frosts, it needs additional reinforcement with various solutions.

For the corrosion protection of the reinforcement layer, it is necessary not only to carry out all construction work correctly: pour reinforcement with concrete completely, eliminate air pockets, but also treat the metal with special mineral substances. Such substances cover the reinforcement with a layer of oxide and erect an additional barrier to moisture.

In order to prevent the condensate accumulating on the surface of concrete tapes from penetrating the pores of the concrete and destroying its structure, the foundation can be covered from above with special bitumen mastic. It allows you to make a smooth layer on which droplets of moisture flow down like a wax surface.Since bitumen mastic is a fairly modern material, the old method of isolating porous concrete from moisture penetration was the foundation coating, which was used to refine engine oil, which made it possible to achieve similar results.

In order to avoid the formation of mold and mildew on the concrete, it is enough to purchase a special solution in the store, which is applied to the solidified foundation, as well as warm the foundation.

Useful tips

Experts recommend to follow a few simple rules when creating a concrete foundation.

- Under the high-rise and heavy structures, it is best to build either a tiled foundation or concrete strip. The tape itself should always be several centimeters thicker than the wall so as not to collapse under its weight. In order to reduce the cost of labor and money, you can build two types of basement, alternating tape and columnar base.

- It is best to fill the entire foundation at a time, however, if necessary, you can do it in parts. The main thing is that the break in work does not exceed several days. Before pouring the next section, it is necessary to re-clean it from debris and dust.

- In order to check the sand for the amount of impurities and contamination, a rather empty transparent tank and ordinary water. The sand is poured into the container, water is poured and everything is well stirred. If there is a strong turbidity, the impurities in the sand exceed the permissible rate and the quality of the finished concrete will leave much to be desired. Sand in this case must be selected from another supplier.

- The technology of installation of a concrete foundation tape type is quite simple, but is associated with large labor costs. It’s possible to build it yourself, but you need to be prepared for the length of the process and the inevitability of minor errors. Nevertheless, with the observance of the basic rules of work, the resulting construction will be quite strong and durable.

For more information on how to make concrete foundation yourself, see the following video.