Selection and construction technology of the foundation for a wooden house

Houses made of wood these days are gaining popularity again. This is not surprising, given the availability and environmental friendliness of this material, as well as its technical characteristics. But even such a house needs a foundation. We will tell you what is better to choose the foundation for a wooden house and how to build it.

How to choose a base?

Most people understand the foundation as a concrete concrete platform on which a house stands. In fact, the foundation has a more complex structure and a lot of species.The durability of the building, as well as the safety of people living in it, will depend on the proper selection of the structure.

If the foundation is chosen and built incorrectly, the house will constantly be damp and rather quickly a mold will appear on the walls, which will cause the smell of rot.

In order to choose a base, the following factors should be taken into account:

- A placewhere the building will be built. After the construction site has been selected, it is necessary to carry out exploratory drilling. This is necessary in order to accurately determine the composition and characteristics of the soil in the place where the supporting base for the house of wood will be installed. It is very undesirable to carry out the installation of such buildings near the ravines and natural reservoirs - in such places the soils are extremely unstable. It is also necessary to take into account the need and the possibility of laying electrical networks, sewage and water pipes.

- Dimensions the buildings. The size of the house will greatly affect the performance of the load, which will fall on the foundation. And not only the height of the building, but also the number of floors will matter.The perimeter of the house, on the contrary, is not so important due to the fact that an increase in the perimeter is directly proportional to the support surface.

- Another important factor is absence or presence of a basement floor or basement.

- Relief surface in the place where the installation will be carried out at home. In the case of the same strip foundation, it will be necessary to carry out very serious and expensive preparatory work, if the construction is carried out on a slope.

- Ground properties Location on. The quality and composition of the soil is easily determined by how the water will go after the previous rain. If the soil contains a high percentage of clay, then it will slowly pass water, and if the water comes to the surface, then the earth begins to become covered with a crust of high density. If sand prevails in the soil, it will pass water very quickly. Loams pass water even faster, but they dry up extremely slowly. If peat prevails in the soil, it will dry for a long time and plants will grow poorly on it.

The depth of the groundwater level as well as the freezing point of the ground will be important.

All this suggests that each type of soil will have a different bearing capacity and density. And on some the house will stand on the foundation well and firmly, while on others the foundation may begin to crawl, which will lead to its destruction and deformation of the building.

What concrete is needed?

Choosing the right place for construction and the type of foundation is only half the battle. The foundation must be made of high-quality concreteand, which will be really durable and will perfectly resist physical and natural impact.

- Concrete category M100 would be an excellent option at the initial stages of construction. For example, if it comes to pouring footings. The foundation of this type of concrete is suitable for the construction of fences, small houses made of wood, small garages, as well as some agricultural buildings.

- If we talk about the brand of concrete M150 then it will be a good solution for a small-sized and mass foundation of a tape type, as well as preparatory concrete work. From such concrete it is possible to build a foundation for a small house on one floor, made of cinder block, gas or foam concrete.Also, this foundation can be used for agricultural buildings and garages.

- Brand of concrete M200 it is used quite often in the construction of residential buildings on one and two floors, where floors are of the light type. Considered brand of concrete refers to the structural in its characteristics of strength and is used in the manufacture of products from reinforced concrete.

- If we talk about categories of concrete M250 and M300, then these options will be an excellent solution for foundations that are planned to be made for large residential houses. M300 generally can be used to fill the foundation, which can easily withstand the mass of a five-story house. M300 is considered the most durable type of concrete that can be used to create monolithic floors.

- There is a brand of concrete M400but it is used exclusively for the construction of multi-storey buildings, the height of which is limited to 20 floors.

So if you need to build a wooden house, then it will be enough marks M200 and M300. The projects usually indicate the desired grade of concrete for the foundation and other technical characteristics of the required mortar.

Usually the most important indicators for concrete are:

- water tightness;

- resistance to low temperatures;

- mobility.

Calculation of the optimal type

Now it is necessary to tell what types of support grounds exist in order to calculate which foundation will be better for a particular case.

In total there are four main types of foundations:

- piles;

- slab;

- columnar;

- tape

- floating

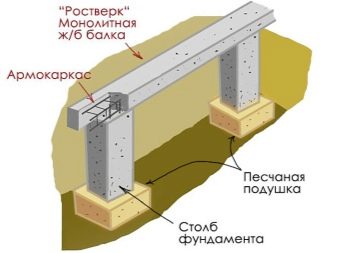

If we talk about pile foundations, then for a wooden house, where there will be no basement or ground floor, the pile construction will be the most suitable option for the foundation. Here the order of marking and the option of placing the piles will be the same as in the case of the columnar foundation.

It should be noted that the pile foundation will be the best solution if the soil is weak and there is a serious slope on the site. Also an important factor in which it would be best to choose exactly this type of foundation will be the presence of ground water near the support base.

Belt options are considered the most popular for the construction of foundations, as they are very easy to build, do not require special knowledge and are excellent for places where the soils are stable and have at least medium strength.

Slab foundations will be in demand where soils are extremely unreliable, have high mobility and are generally considered unsuitable for construction. They represent one large monolithic slab. This type of support base can save the house from subsidence when the ground moves.

Floating foundations are suitable for places where the site for construction is located on a marshy or hemispheric area. In such places, you can only use this type of foundation to somehow cover all the existing shortcomings. After all, these types of soil are completely unsuitable for construction. And the floating foundation will be here as it should be, by the way, as it moves on weak soils. Any other type of concrete base in this situation will simply crack.

Options: device and construction

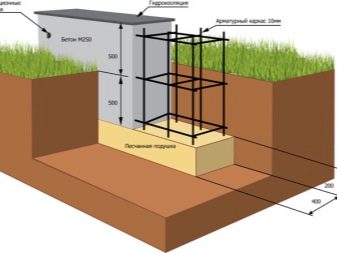

The tape type of the base is made according to the following technology.

- At first it is necessary to carry out a marking, using a cord and pegs. Moreover, it is made so that the corner of the tape was in the place where the stretched cords intersect. When this is done, the plants should be removed from the working platform, followed by a layer of earth.

- Now, in accordance with the markings, it is necessary to dig trenches to the depth specified in the project, taking into account the indicator of the freezing point of the soil. The width of such trenches should exceed the size of the foundation by half a meter in order to work comfortably.

- Now you need to pour a special drainage layer on the bottom. Make it easy using mid-sized crushed stone and sand.

- Now you need to shed all the water and tamp. This layer should protect the base from the effects of any ground motion.

- The next stage is the installation of formwork. It should be made of dense material, so that if necessary it can be used again. For example, if the roof is made of metal, then planed board can be used for the formwork. After removing the board can be used for crates. If the roof will be made of shingles, you can use plywood. And in order to protect it from the effects of concrete, before carrying out the reinforcement of the formwork wall can be covered with a film of polyethylene.

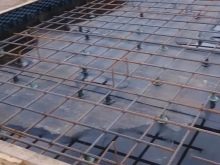

- Reinforcement is carried out by bars of steel, the diameter of which is 7 millimeters. The grid in this case can have either 4 or 6 rods.But then everything will depend on the size of the foundation. The greatest distance that can be between the bars is 40 centimeters.

The strip foundation will be completely ready in 28 days. If the weather is hot, it is better to cover it with a film and from time to time to water it. If the concrete dries too quickly, it may cause cracking. After this period, the base will be ready for use.

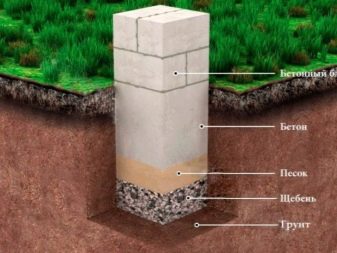

The manufacture of a columnar foundation type involves the following steps:

- First you need to prepare the site. This is done simply - it is necessary to remove all the plants and the soil layer.

- Mark up the foundation. This can be done with the help of a peg, which must be placed in the places where the pillars will be mounted. The distance between their axes should not be more than two meters. They must be placed at each intersection or junction of the base around the perimeter of the marking, as well as under the internal partitions.

- We drill wells for pillars. The depth of the pillar should be greater than the level of freezing of the ground at the place of installation of the foundation by about forty centimeters.

- At the bottom of the pit is a cushion of gravel and sand.First, we pour a sand layer with a thickness of about 15 centimeters, after which we syphem the middle-gravel gravel and we tamp down both layers. For reliability, you can shed all this water.

- Now we make reinforcement with reinforcement from steel with a diameter of from six to eight millimeters. The frame of this grid is boiled on the surface, and then lowered vertically into the hole. Both 4-rod and 6-rod reinforcement can be used. But then everything will depend on the size of the pillar.

- Now we mount the formwork we need height. For a house made of wood, the projection of the pillars above the ground should be no more than half a meter. All the upper sections of the formwork must be placed clearly horizontally and at the same height along the elongated cord. Ogolovki pillars can be made of brick masonry.

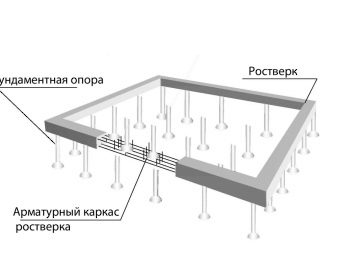

- When the pillars are ready, the base of the house, the grillage, is put on them.

The main part of the pile structure will be metal screw piles. They are inserted into the ground so that the upper ends can be aligned with the tensioned cord. Installation of grillage is carried out on the posts. It is usually made from the following materials:

- timber;

- metal profile - channel or beam;

- cast concrete grillage.

The advantages of such structures will be the absence of the need to carry out earthworks and quick installation of the foundation. If we talk about the shortcomings, then they can not make a basement.

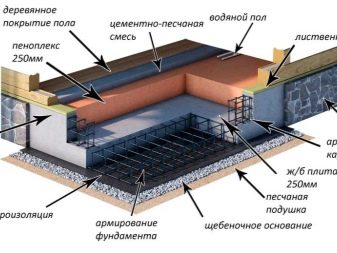

Slab foundations are made according to the following technology:

- the site is marked with the removal of plants and soil layer;

- soil tamping with the use of a vibration plate, which will allow to precipitate a depth of up to 50 centimeters;

- now the bottom of the pit must be compacted;

- a geofabric is placed on the bottom, and in such a way as to overlap the walls;

- we install a drainage layer from gravel and sand, we level it and we stamp;

- now we are doing drainage bedding and we are installing the formwork;

- we lay the insulation layer of foam polystyrene plates, wrap everything in geofabric;

- waterproofing is now done with mastic from bitumen, but before that it is necessary to treat the surface with a primer in accordance with the recommendations on a pack of bituminous resin;

- install reinforcing mesh of steel bars with a diameter of 8 millimeters, the distance between them should not exceed 40 centimeters, and the thickness of the plate should also be at the level of 40 centimeters;

- now we do concrete pouring. It is necessary to do it in the continuous mode in one run. It is best to use the services of a concrete pump and concrete workers, and then you will need to use vibrators for concrete.

You can make a floating foundation using the following algorithm:

- first, a trench is being dug around the perimeter of the proposed construction;

- now a cushion of crushed stone of 20 cm thickness is placed at the bottom of the dug trench;

- on top of it is put lightly moistened sand, which must be well tamped;

- it is necessary to water this sand for two or three days, then ram it with a special shield;

- we install formwork and rebar;

- we pour concrete into the formwork - it should only be done by pouring high-quality concrete - the same as in the construction of a conventional foundation;

- Cover the base with a polyethylene film and leave for one week.

Make any of the above foundations is quite simple.

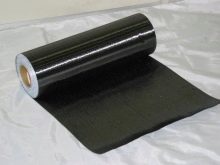

Waterproofing and laying the first crown

The next step is to create a horizontal waterproofing. For its formation is applied mastic based on bitumen and roofing material.First you need to level the working surface, then apply an even layer of mastic, which should then be covered with roofing material. If there is a need, then the edges of the material must be simply cut.

Through this procedure, you can protect the walls of the house from moisture that will come from the soil. In addition, if the building shrinks, the walls will not crack due to the waterproofing layer made.

If we talk about the waterproofing materials themselves, then you can use any kind of injection and roll.

If construction comes from scratch, you can first treat the horizontal surface with Penetron, which will create a waterproofing barrier.

On top of the waterproofing layer, brickwork is set with a height of 5 rows of bricks. From the outside, this clutch is solid and holes are left for ventilation. From the inside, they perform in the necessary places the excavations for the lag of the subfloor. It should be remembered that the lags must be at the same distance from each other. The distance should not be less than 60 centimeters.

Now you should set the logs.To do this, the ends of the already prepared bars are first covered with an antiseptic, and then turned into roofing felt. But the ends of the lag should be left open. Lay the logs on the foundation so that their ends are in the grooves made in the brickwork. The slots are filled with foam.

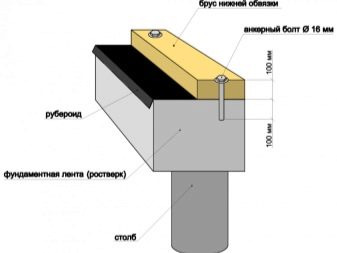

The lower crown of a wooden house deteriorates faster than anyone. For this reason, the design should be as suitable for repair. In order to make the installation of timber on a concrete plane, there are two technologies:

- In the first case, a rod is inserted into the monolith of the grillage, tape or slab at the stage of concreting. When the first timber is installed, holes are drilled in it and it is put on the protruding dowels.

- The second method is a stud. Its essence is that when casting, the stud is immured into the foundation. Its height should ensure the passage through the bar and the placement of the nut with a wide washer on top of it. After tightening, the remaining end is cut with a grinder.

The fastening is done on the pillars with the help of threaded rods or dowels, and on the screw piles they can be fastened using self-tapping screws or additional plates can be attached.

Strapping is a necessary element of the log house. It represents the lower crown of the house, which serves to strengthen the base, in which there is no sense to gash floor logs. But the walls of wood, even if it is glued laminated timber, is difficult to attach to the foundation. To perform such a task, a thicker timber is taken as the first crown. First you need to have on hand fasteners. It is necessary to check the flatness of the surface of the foundation. If necessary, the unevenness must be removed. Now the beamed crown must be put on the roofing felt and make the coupling in the paw.

In the bars, which we will lay on the bottom row, we drill holes. Their size will be larger than the diameter of the anchor studs that were previously placed and concreted at the top of the foundation. After that, drilled bars should be put on anchors. Now they put under the wide washers that are fastened with nuts. We determine the exact location of the corners using the level. After that, you can mount the vertical guides for the construction of the frame.

Old building: features of the base

Houses made of wood and today are the main buildings in many localities.Old buildings were made using cheap materials, and therefore today their owners have to think about how to build a foundation for a relatively new or old house.

Causes of destruction

If we talk about the causes of the destruction of the foundation of such houses, there are several:

- the soil type was incorrectly defined and the wrong foundation type was installed;

- unsuitable materials were used during construction;

- impact of natural and anthropogenic factors;

- the wooden house was rebuilt and rooms were added.

Of course, this is not a complete list, but it gives an idea of the reasons that may necessitate the creation of a new foundation or pour concrete in order to avoid the destruction of the old.

Condition analysis

In order to change the base or repair it, it is necessary to analyze its condition. For this you need:

- Dig a ditch half a meter wide;

- identify the base material and see all the problems.

And then you can make a decision.

Repair or replacement: stages

Step by step instructions that will allow you to change the foundation:

- dismantling the corners of the foundation and preparing the ground;

- the creation of a reinforcing frame that will improve the bearing capacity of the structure;

- installation of formwork;

- pouring concrete;

- waiting until the concrete hardens and the design strength of the corners is reached;

- replacement of the remaining sections.

For a complete replacement, the foundation is divided into segments of 2 meters in size. Dismantling the plots is done through one to ensure stability.

If it is necessary to carry out repairs, then here is the procedure:

- dig a trench around the base;

- we drive parts of the reinforcement into the old base so as not to destroy its remnants;

- remove problem areas of the foundation;

- We fill the trench with a thin concrete mixture, but this is done gradually so that the solution can get into the soil and the old foundation.

Expert Tips

- Be sure to carry out the preparatory work and carefully determine the type of soil on the site where the construction will be done. Choose the right type of primer for your home to avoid future problems. Also, do not neglect the use of good concrete, as in the future, savings in this matter will result you sideways.

- It should also be at the design stage to clearly know what kind of house you need and what it should be.Otherwise, if you want to change something after filling the foundation, such a construction is unlikely to last for a long time.

- Another point to be said is that in no case do not violate the technology of building the foundation. Everything that needs to be done should be done according to the instructions. Otherwise, there is not only the risk of deformation of the house, but also a risk to the lives of its tenants.

For information on how to install a pile foundation for a wooden house, see the following video.