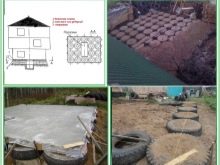

Technology for the construction of the foundation of tires

Any developer cares about minimizing construction costs. This issue is relevant in the construction of country houses and other buildings. Since one of the most important items of expenditure is the construction of the foundation, many use the opportunity to save on materials for it. Often in this case old automobile tires are used, since they are practically free, and at the same time they have a set of qualities and properties necessary for an excellent result of work.

Special features

The first to build the foundation of old tires was the Petersburg-born Mikhail Semykin, for this reason the construction bears his name.In construction, he used unnecessary tires from trolley buses. Semykin watched the structure for about a year, but did not record even the slightest changes during this time. After that, he developed a unique technology for which a patent was subsequently obtained. A vivid example proving the reliability of the foundation of this type is the private house of Mikhail Semykin, which has 3 floors and occupies an area of 260 square meters.

This method of building a foundation has become widespread in the market due to the fact that it does not require large financial expenditures. It should be remembered that, besides the tires themselves, other construction materials will be required for the work.

If the ground is unstable, it is rather difficult to build a foundation on it. Especially complicates the situation of its deep freezing. This type of base is suitable primarily for use in cottage and country estates. It can be built as a frame house, and a bath, garage, gazebo and other buildings. The design will be stable in the season when the ground becomes mobile. In addition, for such foundations require a very small amount of concrete, which is also beneficial for the developer.

pros

All materials used in construction have their own distinctive features, advantages and disadvantages. Old tires are no exception.

- Among the advantages of professionals and consumers in the first place note significant cost minimization. This is due to the fact that it is easy to find worn tires, a huge number of them are located in car-care centers and car service stations. As a result, the material can be purchased almost free of charge, spending mainly on the delivery of tires to the construction site.

- Foundation, built on the basis of old rubber tires, has a long service life, since the materials do not lose their qualities with time and remain elastic. On this basis, it is quite possible to build a house of wood, it can withstand quite serious loads. In addition, the foundation will be provided with reliable waterproofing, regardless of whether the soil moisture rises or not. The impact of water in such buildings is not terrible, respectively, the microclimate inside the building will be quite favorable.

- If the building is located in areas with high seismic activity, soil vibrations will be compensated by material damping. In addition, such bases are resistant to temperature fluctuations. And also it should be noted that the foundation of automobile tires can be made independently, and this will lead to a decrease in the financial costs of the developer.

Minuses

The main disadvantage of automobile tires is that they are able to decompose under the influence of high temperatures and at the same time emit harmful substances into the atmosphere. This disadvantage is compensated by the fact that the tires are located below the ground level or not high above it, therefore direct sunlight and overheating of the material are practically excluded. Not too aesthetic appearance can be closed with cladding materials of different types. The only thing that cannot be bypassed is that the base will not withstand heavy brick and block structures.

Kinds

Tire foundations can be divided into three main types:

- slab;

- tape

- columnar (point)

Attitude to a particular type depends on the method of laying tires. Slab is used if the load needs to be distributed over as large an area as possible when the soil is weak and swampy.

Belt implies wider tires, responsible for load distribution, it can be used in the construction of household premises and houses made of lightweight materials. In the case of a columnar foundation, the base is pillars. In this case, it takes a longer time to process the installation, but consumers note the durability and reliability of the design.

How to do?

The first step is to prepare a draft and an approximate estimate. But you also need to calculate the load, and determine the type of soil. The drawing should be initially made on paper, and during the execution of work it is strictly necessary to follow it.

For laying the foundation of old automobile tires, besides the wheel products themselves, other tools and materials are required:

- shovel to dig a pit;

- rake for leveling the surface;

- gravel and gravel to fill the voids between the tires;

- cement mortar and sand for it;

- fittings;

- building level;

- broken bricks to fill tires from the inside;

- roofing material from which the leveling layer and waterproofing will be made.

The technology of installation of different types of foundation has its differences.

Slab

Before erecting any of the foundations, you must first clear the area and remove the garbage. Removal of the plant layer should be carried out at a depth of about half a meter, after which the platform must be leveled. Further, fragments of brick or rubble are filled up, again leveling and compaction.

It is better to use tires from the wheels of heavy trucks or other major vehicles. Large size tires must be packed in rows and very tightly, and then filled with roofing felt, carrying the function of a waterproofing agent and holding the gasket. Further inside the fragments of brick, earth and sand are poured. The packing must be laid as tightly as possible; the damping properties of the tires and the level of load on the structure depend on it. In cases where the base must be made as rigid as possible, it must be poured with concrete.

Next, you should fill the voids between the tires with prepared materials, with the exception of sand, which can give a drawdown. After that, formwork is installed, which should be wide enough to cover the outer edges and protect them from the negative effects of sunlight.When this work is done, the base is covered with roofing felt to improve the waterproofing properties.

Next is the reinforcement structure. Use welding in the preparation of the frame is not required. After that, it is time to pour the foundation with concrete. This process should be approached most responsibly, because for the most part the final performance of the building depends on it.

When concreting, first of all, you need to clean the formwork and the work site itself, remove debris and oil stains. After that, beacons are installed, which will determine the level of the concrete surface. The concrete mixture itself must be plastic so that it can easily fill all voids without using additional tools. Concrete can be condensed using special mechanisms or manually, as long as the process is carried out qualitatively.

The base itself should be as smooth as possible, this is verified using the construction level. The maximum deviation in this case is 10 millimeters per meter. After this, the construction is left for a period of about a week so that the concrete will gain strength.The formwork is removed one day after the mixture is laid. The finished foundation looks like a monolithic slab; structures of the structure are installed on it. The lower parts of the structures must be fixed to the anchors.

Tape

The technology of installation of the tape base, despite the similarity with the slab, has its own characteristics. First of all, it is necessary to determine where the axes of the bearing walls and partitions will be located. At a distance of at least a meter from the axles, pegs are set. This is an important condition, as it helps to properly distribute the load.

Further it is necessary to dig a trench in accordance with the location of the axes. Its width should exceed the width of the tires, and the depth should be less than the ability to freeze through the soil. Tires are stacked in at least two rows and filled with prepared materials /

Corner tires, as well as those located at the intersection with the bearing partition, should be fixed with metal rods installed in the ground. After this reinforcement is made.

Columnar

When installing a columnar foundation, before starting work, a thick layer of soil is removed.After that, you need to dig a pit of the required size. It is filled with rubble, which is thoroughly compacted.

The marking is applied using pegs on which tires are mounted. It should be borne in mind that the surface must be perfectly aligned. Next, the tires are filled with rubble and broken bricks, after which they should be poured with concrete. It is necessary to wait a few days, and only after that proceed to further work on the laying of the timber.

Tips and tricks

According to consumer reviews, the foundation of old car tires is an excellent option for suburban construction, with which you can minimize costs. It often happens that you don’t have to pay for the tires themselves, and you can do the installation yourself, without attracting specialists, and, consequently, saving on their work. Therefore, this type of base is quite popular in the construction of villas, garages, sheds, baths and utility rooms.

It should be noted that the moment that the tires will serve as a support for wooden supporting structures. They are resilient and not afraid of vibrations of the base. Foundation ditching is not required.

Experts recommend paying close attention to whether the support has a horizontal level.

This violation is easier to prevent in the course of work, than to deal with it later. How exactly the support will be tiled should also be thought out in advance to give the building the most elegant and aesthetic appearance. And also it is worth using rubber, which is as thick as possible. In addition, during the work should protect the foundation from exposure to ultraviolet rays.

To learn how to make the foundation of tires for the bath, see the video below.