Description of basic pile driving methods

The construction of any capital building begins with the construction of the foundation. The appearance, performance, durability and safety of the building depends on how correctly its type is chosen and the installation work is carried out. Today, more and more often, a pile foundation is used in the construction of objects for various purposes.

Special features

Driving piles rely on strong layers of soil, and therefore are characterized by high bearing capacity. Their use, moreover, prevents the deformation of dangerous layers of soil, which under other conditions is fraught with uneven subsidence of the structure.

Piling is done in the following types of soil:

- loose sandy and medium-strength soils;

- flowing and plastic sandy loam;

- tight, flowing and soft plastic clays and loams.

If the piles go no more than 200 cm beyond the soil, then this technology can also be used on clay soils of flowing consistency.

Different types of piles are used for driving. If we talk about the shape of the section, it is:

- round (solid and hollow);

- Taurus;

- square.

Depending on the material used emit piles:

- metal - suitable for the construction of large objects of brick, on the basis of a wooden frame, as well as for the construction of frame houses;

- reinforced concrete - used for monolithic industrial and multi-storey facilities, recommended for moving soils;

- wooden - suitable for private houses, cottages, small bridges, temporary buildings.

Depending on the method of manufacture - monolithic and welded.

Selection criteria and features of wooden piles are determined according to GOST 9463-88. For other products there are regulations.

Regardless of the type of pile, they must meet the following requirements:

- one element must withstand a large load;

- high crack resistance;

- resistance to high variable load, ability to function in difficult hydrogeological conditions.

For pile driving, special equipment is applied that exerts a static (constant indentation) or dynamic (shock) load on the elements. Works are preceded by geological survey and driving a test element. The last action allows you to see how accurate the theoretical assumptions about the nature of the soil, to evaluate the behavior of the pile in the soil.

After driving the test element, a break is made for 3-10 days (exact dates depend on the type of soil), during which they continue to observe.

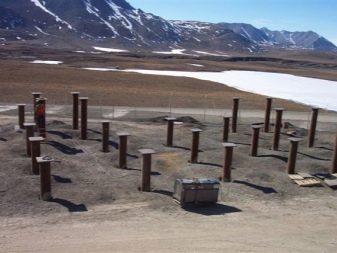

If the test blocking was successful, installation of all the supports is made, organization of the foundation, at the end of which the foundation is laid. The latter involves closing the above-ground part of the base in order to protect it from negative environmental factors. Zabirka can be done with the use of brickwork, boards, concrete solution. The resulting basement is then faced with a suitable material.

The main advantage of the pile foundation is, of course, the possibility of erecting structures of medium and large size on hazardous, prone to shattering and plasticity, soils. One item withstands a load of 1.5 tons.This, in turn, allows to reduce the number of piles, and, at the same time, reduce the estimate. The cost of the pile foundation will be lower compared to the cost of organizing a tape or monolithic analogue.

It is important that the elements sink into the soil below the level of its freezing, otherwise in winter they will be pushed out. Partly to prevent this, as well as to reduce the pressure force on the elements, allows the waterproofing layer in the form of 2 layers of roofing material.

In addition to the obvious, the method of piling has the following advantages:

- nearby buildings do not experience dynamic loads;

- the possibility of building on relief soils, soils with a significant slope;

- maintaining the overall appearance of the landscape;

- high speed of foundation construction, no need to wait for the foundation to gain strength;

- suitable for all types of buildings;

- makes almost any site suitable for construction.

Ways

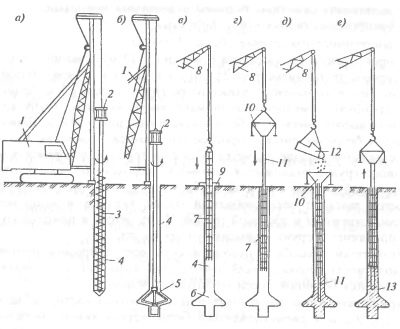

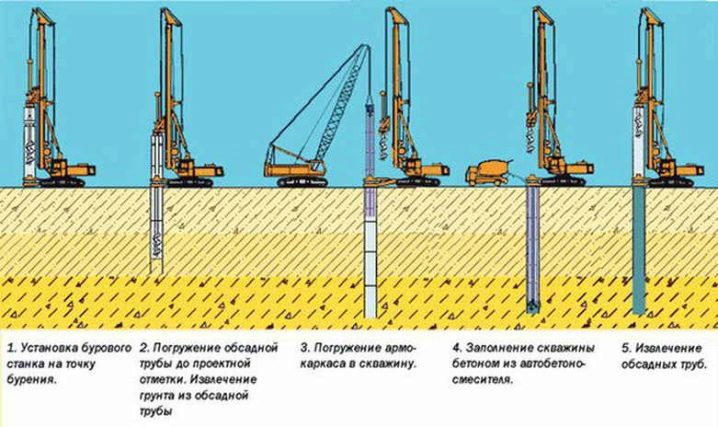

A feature of the pile driving technology is the need to pre-drill wells of the desired depth. The next step is the organization of the pile shaft. This stage can be conducted depending on the type of soil in one of three ways:

- dry - made without fixing the walls of the support;

- with the use of clay, which avoids the fall of the well;

- with the use of casing, allowing to fix the support.

In addition, the driving process itself can be done in different ways:

- by means of a blow;

- vibration method;

- by indentation;

- screwing method;

- using leader wells for support.

Sometimes several methods are applied on the same foundation. Let us consider in more detail each of them.

Pile driving involves the use of a pile installation or other special equipment (for example, an excavator) on which a hydraulic hammer is hung (either diesel or pneumatic hammer) for driving. The diesel hammer is a simple but effective hammer. It operates regardless of the availability of energy sources, has high performance, weather resistance.

This technology is considered one of the most affordable, since it is not associated with increased financial costs, it can be used on soils of any type.

The essence of the driving method is based on the impact energy.With each stroke on the tip, the element goes deeper and deeper into the ground until its point rests on a solid base.

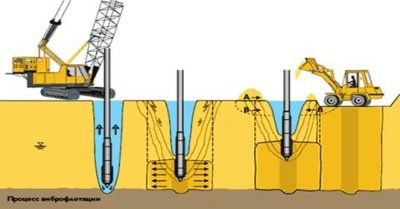

Vibration immersion involves reducing friction between the lateral surface of the supports and the walls of the well, so the method requires less stress. When vibro immersing the displaced soil should be compacted around the pile, since this is directly related to the strength of the future foundation. It is carried out with the use of submersible tools, hammers and special installations, which provide vibrations and deformation of the soil under the tips of the piles and in the area of their side walls.

Vibratory pile driver in this technique is effective on moisture saturated soils. For dry and dense soils, spring-type vibratory hammers are more suitable.

The indentation technology is one of the most silent. It is carried out due to a certain load on the piles, because of which they literally “fall through” into the ground. The load comes from the vibratory pile driver and the hydraulic jack, it is important that the piles are pressed under the influence of its own weight.

The process involves several cycles of deepening and subsequent extraction of the support,until its point stops and reaches the design depth. Suitable for most types of soils, including deep-seated dense layers. This method is not suitable for piles driven in to a depth of over 6 m. Due to the size of the equipment used, its placement requires a section of at least 500 square meters. In addition, it is quite an expensive way to organize a pile foundation.

Screwing technology involves the use of metal or reinforced concrete (RC) piles, which, in addition to the tip, have blades. The latter are necessary for immersion, screwing the supports into the ground. This method is used on flooded and fragile soils, is widely used in urban construction, because it does not create noise and vibrations, does not deform the soil layers of neighboring objects.

The method of immersion of supports is considered the most silent safe for a landscape. It is suitable for rocky soils, soils in the permafrost zone, soils with hard (up to 20%) inclusions.

The essence of the burozabivny method is that a hole is made in the ground (a leader well), the diameter of which is less than the diameter of the pile.The height of the resulting well corresponds to the height of the pile without an edge. After that, the support is driven into the well.

A variety of immersion method is a booster pump. In this case, the diameter of the well is slightly greater than the diameter of the piles, so after immersing the latter, the free space between the walls of the hole and the walls of the support is filled with cement-sand or soil mixture.

Drilling is carried out with the use of drilling rigs, equipped not with pile hammers, but with drill rotators. The latter provide a strictly vertical direction of drilling, which is a key indicator of the quality of drilling.

This method is expensive because it requires the involvement of special equipment. However, on some types of soil, as well as in conditions of dense construction, it remains almost the only one.

How to choose?

The choice of a method of pile driving is primarily determined by the characteristics of the soil. So, impact equipment is unacceptable to use in soils with solid inclusions (stone, gravel, gravel). The clogging method will not work even with a close location of a construction site with exploited objects, main pipelines. In short, where noise and vibration are prohibited.

The method of vibrodiving is optimal for water-saturated and sandy soils, but it is not available when it comes to dense and sedentary, especially rocky soils.

An important selection criterion is the consumption of piles and, accordingly, the cost of work. As a rule, for premises of regular operation, it is necessary to choose between RC and screw piles. The bearing capacity of reinforced concrete supports is higher, however, they are installed with the same pitch as the screw ones. That is, to reduce their number will not succeed.

For the construction of a large object, including a country cottage, you should choose ZhB support. Under the baths, sheds and outbuildings, temporary objects purchase of concrete piles of piles is irrational, you can purchase and screw analogues. However, the latter are not recommended for use on strongly acid soils, since the service life of the piles will be short.

But for soils with significant differences in height or on watered soils, it is better to use screw piles. Reinforced concrete (even when using compound modifications) in this case tend to fail, which is not the case with screw analogues due to their wider base.In addition, the latter can be increased to the required length - as long as the base does not rest on solid layers.

If we compare the laboriousness of the methods, then all the piles installed by the driving method require less installation time. As a rule, for this purpose it is only necessary to deliver special equipment that moves on it on a crawler track. During a shift, such installations are capable of driving up to 40 piles, that is, creating a whole foundation in most cases.

The important point is that when choosing the indentation technology it is important to assess the size of the section and the pressure used on the equipment supports.

The introduction of screw piles into the ground implies the use of electromechanical equipment or a hole, through which a gearbox is installed in the mounting hole, which ensures the screwing in of the supports. If access to the construction site is difficult or for other reasons you cannot use special equipment, manual installation of the piles is possible. The process will be long and laborious.

Tips

Regardless of the chosen technology and size, the purpose of the building, diagrams are compiled that reflect the bearing load of the supports, the depth of their depth, pitch, diameter, and so on.

If the structure provides for heavy structures, for example, stoves, fireplaces, then they need their own mini-foundation. It is not associated with the main foundation and must be built on its own calculations.

When driving a pile with your own hands, you should remember that it should be set below the level of soil freezing and pass through all weak layers. The only way to achieve the strength and reliability of the foundation of the pile type.

If it is necessary to hammer a support into an excessively dense soil to a great depth, a technology of washing away can be applied. To this end, water is supplied along the pile under pressure into the well. It serves to soften the soil and reduce friction between it and the walls of the piles.

Drive piles, as already mentioned, to solid ground, the depth of which corresponds to the design documentation. It is important to make sure that the element has reached solid layers, and has not rested, for example, in a stone. Otherwise, it is impossible to avoid the pile skew during the operation of the house, which affects the geometry of the structure as a whole.

It is better to immerse or block piles in the warm season, after the upper layers of the soil have thawed out.If it is not possible to carry out work before the frosts, then it is possible to conduct them in the normal mode, provided that the ground is frozen to a depth of no more than a meter.

If the freezing is more significant, you can use a special device - a “steam needle”. It represents the tube on which it has a hole - hot steam comes out of it. The tube is lowered into the well, contributing to the defrosting of the soil. For frozen soils, the drilling method with preliminary drilling of leader wells is also suitable.

Attempts to hammer piles into frozen ground by other means will at best lead to its loosening as the soil thaws, and at worst - to deformations.

For hammering piles of small diameter to a shallow depth, you can use a hand hammer. For larger construction use an electric or hydraulic hammer. Their cost is high, but it can be rented when it comes to private housing construction.

When using the drilling inlet method, you must first take care of the removal of the soil during drilling. Otherwise, the level of construction will rise by an average of 0.5 m.

Depth of the well is of strategic importance in leader drilling.It should be half a meter shorter than the support. Otherwise, it will not be possible to ensure that the pile is held by the primer.

About vibrodiving, indentation and pile driving, see the next video.