Formwork for the foundation: characteristics and features of installation work

Building construction begins with the installation of the foundation, the main element of which is the formwork. In order for the structure to be strong and its construction reliably served for many years, it is important to correctly assemble the mold for casting the armored belt. It’s quite realistic to do it yourself, but it’s important to do all the calculations and stick to certain technologies.

Device and purpose

The formwork is a horizontal or vertical form, which is used to fill and screed the foundation of the house. The main components of its device are removable shields and blocks that hold together with the help of special fixings and fittings. The concrete mix is poured into the formwork after the manufacture of the reinforcement cage, where it hardens and acquires strength,then it is dismantled and the subsequent stages of construction continue. These structures are also used in the case when it is necessary to repair the basement of the building.

In the process of formwork production, it is important to ensure that it meets the following requirements:

- was stable, durable and not deformed under the influence of loads;

- had a dense structure without cracks;

- provided high quality surfaces, eliminating the appearance of curvature and sagging;

- corresponded to the technological characteristics and did not create difficulties when installing the fittings and pouring the solution;

- possessed turnover, those are subject to repeated use.

The formwork is often made of plywood, wood, steel, but recently options made from synthetic materials have also become extremely popular.

Depending on the design conditions, this design can be combined simultaneously with several materials. For example, the supporting and supporting elements are made of metal, and those that come into contact with concrete are made of plastic or waterproof plywood.

Kinds

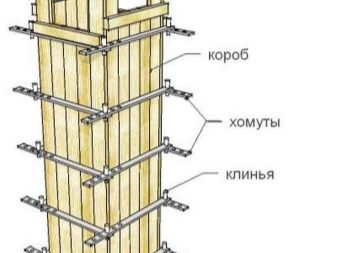

Today, there are many types of formwork, which can be divided into general construction (universal) and a special group for the construction of special structures. The most common type of formwork is dismountable-movable, it is chosen during the construction of not only the foundation, but also partitions, walls, beams and columns. For the manufacture of large-sized fragments and foundations, as a rule, preference is given to the beam view, and if you need to install buildings of great height with varying geometry, then lifting-adjustable formwork is used.

In addition, in modern construction also use the following types of structures:

- Stationary. The formwork is made of wood and it is great for laying the foundation, which has non-standard complex shapes. It is easy to assemble the details of such a device — shields of the required size are knocked out of the boards, fasteners are made and special stops or lintels are put in to reinforce.

- Perestavnoy. It is a universal type of formwork, which can be used reusable. The installation is made of steel and externally it resembles the assembly of the designer.Shields are connected to each other both across and along. The result is a prefabricated structure, twisted with the help of tubes and pins, into the cavity of which concrete is poured. After the initial setting of the mortar, the studs and shields are removed, and the tubes are easily knocked out and can be used for subsequent work. Holes formed from the tubes, smeared with cement mortar.

- Suspension. Allows you to lay the horizontal foundations, designed for landings and other floors. It is a folding formwork, its shields are attached to each other and suspended on beams, thereby limiting the movement of concrete down.

- Sliding. This design is used in the construction of high buildings with a typical cast-in-place. It can be operated repeatedly. The main feature of the device is the presence of a special mechanism due to which it independently rises up.

- Mobile. It can be both temporary and non-separable design, having a round, rectangular or square shape. It is considered an indispensable option for concreting large horizontal foundations, as it allows you to simultaneously fill the upper and side parts of the structure.After the mortar has set, the formwork is moved to another place with the help of wheel supports or rollers.

In addition to the above types, waterproofing formwork, which is often used in the construction of private houses, deserves special attention.

Due to the unique device and special characteristics, it not only provides high-quality concreting of the base, but also reliably protects it from moisture during operation. It is usually erected from wooden shields or prefabricated blocks. Depending on the formwork used disposable or repeatedly distinguish between removable and non-removable types of structures.

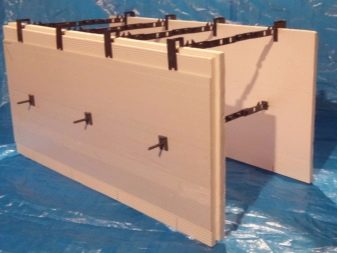

Non-removable

A distinctive feature of this device is that it is laid with the use of insulation material, so the building is warm. Fixed formwork is versatile, as it can be used in the construction of private and high-rise buildings. In addition, it allows you to pour the foundation of various shapes with mortar.

The main advantages of this formwork include:

- The speed of the construction process. Assembling the structure is easy, so it reduces installation time.

- Resistance to low temperature. Concrete work during monolithic construction can be carried out at a temperature of -10 ° C, as the flooded frame is additionally insulated.

- Reducing the cost of the foundation and the total weight of the structure. To lay the foundation there is no need to hire heavy equipment and craftsmen.

- High rates of heat and sound insulation of the building.

- Foundation strength and durability of monolithic construction.

- The ability to install hidden engineering communications. Engineering systems can be mounted directly into the frame and removed in separate places through the holes in the formwork.

- Protection of the structure against natural and biological threats. The building is not exposed to insects and rodents, is resistant to mold and does not rot.

As for the drawbacks of this type of formwork, there are few of them:

- The need for external and internal decoration. The only exceptions are designs made of cladding panels.

- Low vapor permeability of thermal insulation material. Therefore, the construction requires additional installation of high-quality ventilation.

- The building should be grounded, as iron reinforcement is placed inside the walls.

Removable

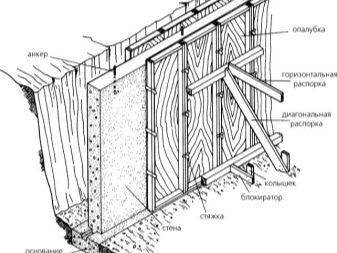

The most popular and common form of formwork in construction is considered to be removable. It is made of various materials, depending on the size of the concrete area. Usually give preference to moisture resistant shields that can be used many times. Prefabricated elements of the device are attached to each other with gaskets, bars and screeds. The result is a solid and durable construction of any length and shape, which at the end of concreting is dismantled.

Removable models differ in their purpose and can be used not only for laying the foundation, but also for casting individual reinforced concrete elements. Formworks of both factory production, and modular or inventory, made of metal are on sale. They can be used several hundred times in monolithic construction.

The positive characteristics of removable formwork include:

- repeated operation;

- accelerating the pace of construction;

- the ability to erect buildings of any shape and size, without using for this additional elements;

- easy restoration and repair;

- savings during re-use.

There are no drawbacks to the removable formwork, the only thing is that it is not recommended to purchase this type of construction for a one-time construction, as its assembly will be expensive.

Variety of materials

Formwork for the foundation can be erected from various materials, the choice of which depends on the complexity of the project and the forms of the foundation. Usually, wood, metal, reinforced concrete, rubber, reinforced cement and plastic are used for the manufacture of construction panels. The remaining elements of the device presented in the form of stiffeners, locks, fasteners and fasteners are made, as a rule, from metal or high-quality plastic.

The most common material for formwork boards are boardsif the design is small-shield, then it can be assembled from waterproof plywood. It will be cheap, but in order for the plywood sheets not to be written from contact with the mortar, they must be additionally impregnated with a special resin. Plywood formwork allows you to give the concrete surface a perfect smoothness, but it is much inferior to plastic and can only be used once.The wooden structure is collected from an array of moisture content of not more than 25%, while preference is given to coniferous species of wood.

If you plan to budget construction of small foundations, the formwork can be made of the OSB, DSP or chipboard sheets.

To create a design, it is desirable to choose plates with a minimum thickness of 18 mm. In addition, this material will be able to serve in the future as a subfloor. To do this, when laying the foundation, the boards are wrapped with a film, after disassembly, they are clean and suitable for flooring.

In that case, if you need to translate into reality the project of bulk monolithic construction, then for the installation of the foundation the best option would be metal formwork. It is made of steel sheets with a thickness of 2 mm and rolled sections. The size of the cells in the metal frame should not exceed 5 × 5 mm. The main advantage of a metal device is its ease of installation, durability and the ability to obtain a high-quality concrete surface. The disadvantage of such formwork is high cost.

In hydraulic engineering construction where the laying of large engineering foundations is required, reinforced concrete structures are used.To prevent the concrete casting from touching the shields, their surface is coated with a special lubricant and fittings are installed. This formwork makes it possible to lay a solid foundation, but its assembly is expensive.

If it is necessary to fill the base, consisting of complex geometric shapes, then use "inflatable" formwork.

It is made of dense fabric, suitable for these purposes and film. By heating the air in the shell, the material acquires the desired shape and is attached to the structure with the help of jute fabric, which serves as an armature between the solution and the device. Then pour a certain thickness of the solution. Such formwork is inexpensive and has no flaws.

No less popular with the masters and plastic construction. It has found application in laying both concrete and foam concrete foundations, which are used for the construction of monolithic buildings of various configurations and purposes. In this case, the boards can be assembled from plastic and polystyrene. Blocks of size 60 × 30 cm are attached to each other with the help of additional elements in the form of channels, angles and connecting keys.Due to the properties of the material, the formwork is made quickly, and the surface of the base is smooth, does not require finishing, the only thing that such shields can not withstand a lot of concrete weight.

In addition to the above options, formwork can also be assembled from a professional sheet and flat slate. Sheets of material in this case it is best to choose a thickness of from 15 to 20 mm and perform reinforcement with wire mesh. Such designs are characterized by high cost and lack of efficiency, but quickly assembled. At the same time, slate formwork has high moisture resistance, is not afraid of temperature changes and has excellent noise insulation. As for the minuses, slate weighs a lot and is characterized by low strength.

Foam formwork is also well suited for fixed construction types.

It performs the role of insulation and cladding, easy to manufacture, but is designed for laying the small foundations. In addition, the foam has a low coefficient of thermal conductivity, so the construction of the foundation eliminates the need for laying insulation. Since foam blocks are characterized by a cellular structure, the material is also distinguished by good waterproofing.

To make a formwork of foam, take a pair of plates, fasten them together with metal struts and the resulting shield set in a trench. In some cases, the plates can spread in the form of waves, protrusions or transverse rows. With the help of foam, you can lay the foundation of any kind: from the belt to the pile-grillage.

Payment

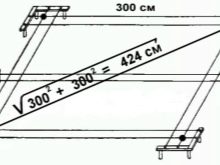

The formwork assembly process should begin with a preliminary design. Therefore, first of all, you need to correctly make a plan and a drawing of the foundation, then calculate all the sizes and decide on the thickness of the fill. Foundation markings should be applied before the formwork is made.

To calculate the consumption of wooden boards for the construction of a monolithic base, you must perform the following steps:

- measure the length of the perimeter of the future structure;

- find the desired height of the foundation, taking into account the allowances;

- calculate the thickness of the boards, according to the design value.

For example, if you need to lay a foundation with a width of 9 m and a length of 15 m with a base height of 50 cm, then 25 cm thick boards are used.

The length of the perimeter of the building is multiplied by 2, then the result is multiplied by the height of the foundation and the thickness of the boards.All calculations should be performed in meters. According to the given parameters, the following calculation is obtained:

(15 + 15 + 9 + 9) x 2 x 0.7 x 0.025 = 1.68 m3.

That is, for the assembly of boards will require 1.68 m3 boards. But it is recommended to buy building material with a small margin. In addition to boards, formwork also requires bars, which will serve as fasteners. As for the calculations for the pouring of the plates, they are performed, knowing the thickness of the plates and the height of the rooms. Consumption of plywood sheets for formwork is calculated based on their size and basement area. As a rule, plywood with a minimum thickness of 18 mm is used for the manufacture of formwork.

Installation steps

Formwork is an important element of the foundation, so without its installation will not do any construction. Despite the fact that the formwork is characterized by complex installation technology, its production is quite realistic to do it yourself. It is important during the working process to control the level of accuracy with which the structure is placed in the horizontal and vertical plane. In addition, all calculations should be carried out correctly, since the evenness of the position of the walls of the future building will depend on them.

To build the formwork yourself, first of all you need to prepare a certain set of tools.as the installation involves the assembly of shields, reinforcement and casting with concrete. It is also important to decide whether it will be a removable or non-removable type of formwork. In the first case, the design is applied reusable and it can be removed after pouring, it should be done when the concrete grabs. The second version of the design is not dismantled, it must be securely fastened with supports and pour the solution.

Regardless of the design features, formwork production consists of the following stages:

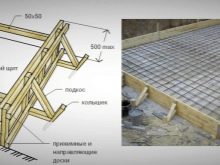

- Land preparation. The territory where the construction is planned is thoroughly cleaned, especially for the site around the dug trench. In order to avoid overlays during the installation of the structure, it will also be necessary to level the soil so that there are no depressions and hillocks. A gap of 1-3 cm should be supplied between the formwork and the ground, this will facilitate further installation, and after splitting it will be necessary to cover it with soil. If necessary, a reinforcing mesh is laid at the bottom of the excavation or trench, thanks to it the foundation strength will increase.

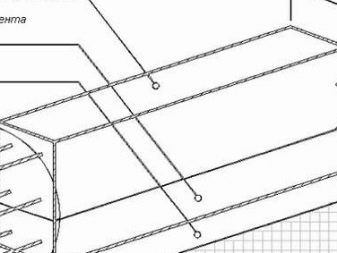

- Making shields. The formwork can be assembled from a variety of materials, but most often for this purpose choose wooden boards and bars. Boards need to be pre-cut into the required length, at least 3 m. They are knocked together with the help of transverse segments, observing a pitch of 1 m. Thus, the assembly of one three-meter shield will require about three knocked-down fragments connected by bars. The difference that will turn out between the length and height of the device will allow you to conveniently “drive” shields along the entire perimeter of the dug trench.

It is necessary to remember that the front side of the boards should be smooth, since the quality of the outer side of the foundation will depend on it.

As for attaching the boards to each other, it can be done with anything: nails or screws. The choice is determined by price, reliability and speed. If the boards are fixed on nails, then it should be provided that their caps are placed on the side of the mortar.

- Mounting clamps. After the shields are ready and driven around the perimeter of the trench, proceed to the manufacture of wooden clamps. Their length, as a rule, should be at least the height of the shields. Since the clamps perform an important role of structural elements and are responsible for the additional rigid formwork when it is poured with concrete, they are placed in the middle of the shields between the strips.In addition to the clamps in the places where the boards are connected, additional support struts are installed.

Shields should be mounted strictly along the horizontal and vertical plane, according to the design of the foundation.

From the inside of the structure and from above, it is necessary to fix them with struts It is important to pay attention to the fact that the formwork is solid and does not have gaps, otherwise the solution will leak and the work will be ruined. In the event that there are minor gaps in the structure, they are easily sealed with waterproofing materials.

- Laying waterproofing. The inner part of the formwork is covered with dense roofing material and perform reinforcement. If desired, the underground part of the foundation can be warmed with foam polystyrene plates. They are best placed on the outside of the foundation.

- Installation of communication systems. This should be done before pouring concrete solution.

How to make a formwork for the foundation, see in the video.