Column and strip foundation: construction technology

The choice of the type of foundation is determined, first of all, by the characteristics of the soil. Where, due to its instability, it is not possible to use the classical tape base, often resort to combined systems. This option is a column-tape foundation.

Special features

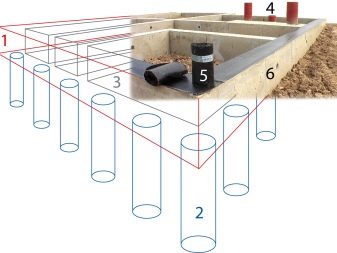

The column-strip foundation combines the leading features of two types of bases - columnar and strip. Such a combined version allows building sufficiently heavy objects on unstable soils.

In the role of supporting elements in this system are the piles, which are driven into the soil below the ground freezing and rely on solid layers of soil, bypassing the soft.Concrete belt base takes the load of the object, evenly distributing it between the piles. The tape binds the pillars without exerting pressure on the ground.

These types of bases are suitable for unstable soils subject to heaving. First of all, these are clay and fine sandy soils, organic soils (swampy, peaty), previously drained and drained. In addition, the use of piles allows construction in areas with height differences. In other words, the use of a pile-foundation base allows to make almost any site suitable for construction.

The strip foundation with the pillars is similar in its organization to the analogue on piles, however, to install the supports, it is not necessary to engage special equipment and drill deep wells. This allows you to do the installation by hand and reduce the size of the estimate.

The advantage of the columnar foundations is the ability to build on “problem” soils, as well as in areas with height differences. However, the device of such a system requires accurate calculations.

In the absence of such work skills, it is better to entrust the matter to professionals.

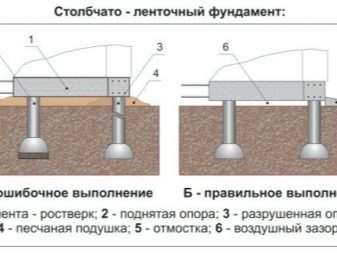

The execution of the tape base on the pillars does not imply a large amount of earthworks and is cheaper than pile analogues. A gap should be maintained between the column-tape base and the monolithic coupler in order to minimize the impact of the ground heaving process on the foundation.

Creating a foundation on the basis of pillars is not suitable for moisture-saturated soils (areas located in lowlands or near water bodies, soils with groundwater). For such areas it is better to choose a pile foundation with a tape base.

From the very beginning, you should decide on the features of the building - its size, number of storeys, the technologies used. The material for the manufacture of pillars, their number and diameter depends on this.

Typically, pillar foundations in combination with tape are used on unstable soils and are intended for small one-story houses with an attic or two-story objects made of lightweight materials. Suitable wall materials are foam blocks and wooden structures (log houses), as well as "skeletons", for the construction of which Canadian and Finnish technologies are used.

Houses made of aerated concrete can also use shallow-foundation. But brick counterparts require the deepening of the pillars and an increase in strength and diameter of the pillars.

Materials

Support columns can be made of several types of materials.

Wood

It is an affordable and easy-to-install material, which, however, has the smallest load-carrying capacity and a short service life. This option can be used as the foundation for small terraces, temporary buildings, cottages.

The best for wooden posts is a diameter of 120-200 mm. Before using, supports should be dried, covered with water-repellent and antiseptic impregnations. This will increase the service life of the pillars. As a waterproofing material used bitumen mastic.

Brick

Brick pillars are very common. They lay out shallow-buried columnar bases of square section with a side width of 40-50 cm.

Concrete

Concrete elements are monolithic or collapsible bases on the basis of concrete, reinforced with steel rods. The standard section in this case is 400 mm.This option is suitable as a basis for capital construction.

Pipes

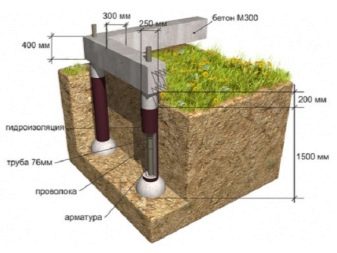

Tubular elements are metal pipes installed in the ground and filled with concrete mortar inside. Reinforcement is used as reinforcement.

Calculations

Determination of the number of piles and their length is made according to the calculation documentation. For sites with sufficiently stable soil, supports with a length of 2500 mm are sufficient. When building an object on uneven terrain, the height of the support takes into account differences in the height of the soil. When building on highly mobile ground, the height of the support should be such that it reaches solid layers of soil plus 15-20 cm.

The number of pillars can be calculated by adding up all the loads on the foundation. To do this, calculate the load (weight) of 1 m3 of wall material and multiply this indicator by the number of cubes of the entire room. This coefficient is summed up with the weight of the floor, ceilings, windows and doors, roofing, as well as the internal equipment (furniture, finishing materials, equipment, communications).

Further, the load factor is multiplied by the reliability factor (this is a constant value according to SNiP).The resulting number should be divided by the value of the bearing capacity of one support.

It should be borne in mind that it is necessary to mount the columns in the corners, the intersection points of the partitions.

The distance between the pillars is maintained in the range of 100-250 cm. The heavier the object, the less distance is maintained between the supports. It is not recommended to increase the pitch by more than 250 cm, because in this case the strength of the finished building is reduced.

For wooden buildings, it is recommended to put pillars with a pitch of 3 m, in buildings of foam and gas concrete - 2 m. For brick houses, this figure is 1.5-1.7 m. In other words, the foundation for a house of foam blocks 9x8 m in average size requires at least 16 pillars, and a wooden counterpart of the same size - 12-14 supports.

Installation steps

In general, the construction of the column-strip foundation is divided into 2 major stages: the creation of a system of pillars and the filling of a shallow-tapered base.

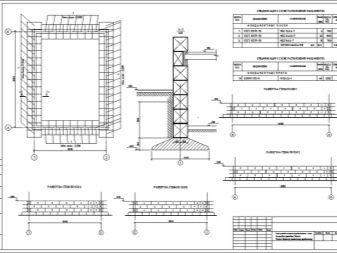

Project creation

The construction of any type of foundation begins with the creation of project documentation. This work is preceded by geological surveys (observation and analysis of the soil to find the optimal type of foundation). The project contains information about the bearing capacity of the pillars, their size, quantity.

The type of foundation considered can be shallow and deep. In the first case, the pillars are immersed in the ground by 40 cm, in the second - 50-70 cm below the level of soil freezing. The choice of a particular technology depends on the type of soil, the presence or absence of groundwater, the characteristics of the object under construction.

The step-by-step installation instruction is not too complicated.

Site preparation

At this stage, the removal of litter from the site, the removal of the ball of the fertile layer and the alignment of the site. On clay soils, the top layer is removed and a layer of sand is poured, which is compacted and leveled.

Plot marking

To do this, use the pegs and a coil of visible rope or thread. The threads must be tensioned at a distance that corresponds to the width of the future tape of the foundation. It is important to follow the intersection of the filaments in the corners; it must be strictly perpendicular. Marking is made at the points of passage and intersection of internal partitions, in the corners, as well as in areas subject to maximum loads.

Creating a trench and grooves for poles

At the location of the strip foundation, a trench about 400 mm deep should be dug.The trench width should be 70–100 mm greater than the depth.

In places of increased loads (according to project documentation), grooves are made, where support columns will then sink. Their diameter is calculated based on the load on the foundation. The higher it is, the larger diameter the pillars should have. A drill is used to create the recess. If the recess is long enough, then at first it is carried out with a drill, then with a screw.

When laying the pillars to a depth of more than 100 cm, it is necessary to build props from durable boards that will prevent crumbling of the ground. If the depth of the foundation is less than 100 cm, the use of props can be waived.

Sand 10 cm thick is poured at the bottom of each depression. With a greater depth of laying of the base, the thickness of the sand "cushion" reaches 30-40 cm.

Installation of supports

At this stage, the posts are lowered into the prepared depressions. Most often used pipes that are filled with concrete. Pre-pipes are waterproofed, for example, by pasting a double layer of roofing material. After that, the pipes as far as they go go into the recesses, after which their vertical directionality is checked.

The next step is pipe reinforcement.For this purpose, a framework of reinforcing rods with a diameter of 12-14 mm and knitting wire is used. The resulting frame should be 12-20 cm protrude from the pipe.

After that, a concrete solution is prepared, which is first poured into the free space between the walls of the recess and the pipes. The pouring height is about 20 cm. Then the cavity inside the pipes is filled.

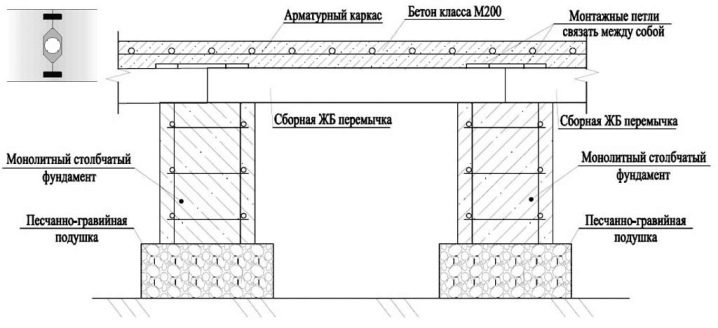

After the solution has gained the necessary strength, proceed to the installation of the tape part. First, the framework of reinforcing rods and knitting wire must be welded to the reinforcement elements protruding from the pipes. Next, a formwork is assembled, consisting of boards about 150 cm wide and not more than 40 mm thick. Instead of boards, you can use plywood, chipboard or sheet metal.

The inner part of the formwork is lined with plastic film or a special membrane, which perform the function of a waterproofing layer, and also allow you to get a smooth and smooth surface of the strip foundation after stripping.

After that, you can start pouring concrete. Casting should be carried out at one time (the maximum break in work is 2 hours) strictly in the horizontal direction.Vertical filling of the formwork will lead to the appearance of joints and cracks in the concrete before the solution hardens.

When pouring, it is important to eliminate the appearance of air bubbles in the solution, which can adversely affect its strength. For this, vibratory pile drivers are used.

After that, the concrete should be given time to build strength, first protecting it with a covering material. As a rule, the foundation is cast in the summer, so the likelihood of its drying is not excluded. Periodic wetting of the concrete surface during the first 1.5-2 weeks of hardening will help prevent this. In the cold season it is recommended to lay the heating cable over the entire surface of the concrete for the entire period of hardening.

After the specified time, the foundation is dismantled, its hydraulic and thermal insulation. The remaining space of the trench is filled with soil, after which you can proceed to the rest of the work.

For information on how to calculate the column-strip foundation, see below.