UWB foundation: innovative solutions for homes

The construction of any building begins with the installation of the foundation, which is not only a reliable basis for the structure, but also ensures the durability of the structure. To date, there are many types of such bases, but the foundation with the use of insulated Swedish plates (USW) is very popular with developers. This material is made according to modern technologies, allows to save on the cost and time of construction, and is also an excellent heat insulator.

What it is?

UWB-foundation is a monolithic base, laid out of Swedish plates, having insulation throughout the area and the perimeter of the sole. This foundation is a finished subfloor for the first floor, in addition to communications, you can also embed a heating system.

Laying plates perform shallowly, as they include high-quality insulation - polystyrene foam, which reliably protects the bottom of the bottom from freezing. In addition, the building material contains particles of graphite, which make the plates durable and resistant to power loads and exposure to sunlight. It is also worth noting that UWB foundation never shrinks - this is very important when building buildings in areas with problematic soil.

Swedish plates differ from conventional multi-layer structures in that they significantly reduce the cost of foundation construction. Such elements can be used, for example, in houses located in areas with harsh climatic conditions, where there is a low temperature and soil moisture in spring and autumn, because these foundations are resistant to frost and protect the structure from heat loss.

They are also ideal for buildings in which unconventional heating is planned using water heating. Heat lines are installed directly inside the plates, and they transfer heat energy from the carrier to the entire surface of the base.

When the construction is carried out on problematic soil, this is also a reason for using UWB technology. Thanks to the multi-layer construction, which is additionally reinforced with durable reinforcement and covered with concrete, the foundation is reliable and allows you to build houses on the ground with a high concentration of peat, clay and sand.

For the construction of multi-storey buildings whose height exceeds 9 m, these plates are also an indispensable element. UWP-plates provide the stability of the frameworks, as well as strengthen log cabins and hollow-panel structures.

Advantages and disadvantages

UWB-foundation is widely used in modern construction, since, unlike other types of bases, it is a budget option and has many advantages. The advantages of this design include, for example, the minimum installation time - full installation of plates, as a rule, is carried out within two weeks.

Also, this material has good thermal insulation, because thanks to polystyrene foam, which is part of the material, freezing of the soil under the foundation base is eliminated, which reduces the risk of subsidence and ground heaving.In addition, significantly reduced the cost of heating the building.

The surface of the UFF is a ready-made rough floor, on which you can immediately lay ceramic tiles without prior alignment. This difference makes it possible to save time on finishing.

The material has high compressive strength and resistance to moisture, so this type of foundation is durable and can reliably last for decades, retaining its original characteristics. During the construction of the Swedish plates, it is also important to take into account their disadvantages:

- The main part of communications is arranged in the foundation, which means that if necessary, they can be replaced, it will be difficult to do so, since access to them is impossible;

- USP plates are not recommended for the construction of heavy and multi-storey buildings - the technology of their installation is provided only for small buildings;

- Such a basis does not provide for the possibility of implementing projects for houses with a basement.

Device

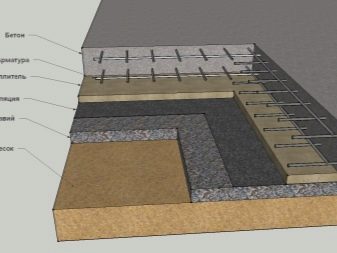

Like any building material, the Swedish plate has its own characteristics of the device. The foundation is monolithic,manufactured according to the latest production technologies and consists of the following layers:

- concrete screed;

- heating systems;

- fittings;

- thermal insulation;

- rubble;

- construction sand;

- geotextiles;

- soil layer;

- drainage system.

Therefore, we can say that The Swedish plate is a unique type of base with a specific structure that combines at the same time waterproofing, insulation and a heating system. Such a universal “pie” allows not only to quickly build buildings, but also retains heat well, creating comfort in rooms. For thermal insulation, sheets of expanded polystyrene are used, thanks to which the foundation is insulated. The reinforcement is made of steel rods with a diameter of 12 to 14 mm - they reinforce the frame of the building and protect the floor from the appearance of cracks.

Thanks to this structure, the UWB foundation, like its Finnish counterpart, is ideal for building a house where you cannot use a strip foundation or foundation on piles. In addition, for this type of construction is characterized by integrity, due to which the foundation is not destroyed under the influence of low temperature and moisture.

Payment

Installation of Swedish plates must begin with preliminary calculations, taking into account the characteristics of the soil, the load of the structure and the effect of precipitation. Therefore, first of all, it is imperative to determine the type of soil on the land plot where construction is planned. In addition, studying the level of placement of groundwater and the depth of freezing of layers of the earth. The main task of the calculations is the drafting of the design, which indicates the thickness of the foundation layers.

For the correct calculation the following data is taken:

- total area of the base;

- USP perimeter;

- height and length of the supporting ribs;

- sand cushion thickness;

- volume and mass of concrete.

The cost of installing Swedish plates can be different, as it depends on the size of the building, as well as the characteristics of laying sewers and water mains.

Construction technology

UWB-foundation is widely used in modern construction, it has many advantages and can be easily installed with your own hands. Since the Swedish plates in their design have high-quality insulation, the base of the building turns out to be warm and does not require additional insulation installation, which saves not only the time to complete the work, but also finances. To independently perform this type of foundation, it is necessary to consistently carry out certain stages of work.

- Land preparation. In the event that a building is built on fragile soil, it must be cleaned of peat and clay layers, or simply covered with a thick layer of medium-sized sand. In addition, the foundation should be placed strictly horizontally. Its thickness is calculated taking into account the thickness of the sand cushion and insulation and can not be less than 40 cm. The bottom of the base is covered with sand and evenly distributed, each layer is carefully rammed.

- Installation of drainage system. A trench is made along the perimeter of the excavated pit, and a flexible pipe is laid into it. Before laying the pipe, the walls and bottom of the trench must be covered with geotextile with an overlap of 15 cm - this material will provide good drainage and strengthen the soil. After that, backfilling is performed, strictly adhering to the dimensions specified in the project. Filled and rammed sand layer must be poured with water.

- Laying of engineering communications. All sewage systems are placed directly on the sandy basis, they are temporarily fixed with clamps and fittings. The ends of pipes and cables are brought to the surface.

- The construction of the wooden frame. From a cut board on the perimeter of the base they arrange a frame. To do this, first put up the rack, then to them with screws fix the boards. To make the frame durable, it is recommended to strengthen it additionally with braces.

- Backfilling rubble. Medium sized crushed stone is well suited for this type of foundation. The layer of material should be evenly distributed over the entire working area, its thickness should not be less than 10 cm.

- Installation of insulation. As an insulator used plates made of extruded polystyrene foam. Warming must be performed both horizontally and vertically. The thickness of the insulation, as a rule, is 100 mm. Insulation tightly pressed to the surface of the wooden frame and formwork. In order to avoid the displacement of the plates during installation, they are fixed with the help of screws, and small holes are made in the areas of the communications outlet.

- Reinforcement. This type of work is carried out in two stages: first, the grillage of the frame is reinforced, then the plane of the Swedish plate itself. The result is a reinforcement cage made of rods interconnected by knitting wire.In order not to damage the insulation, it is desirable to assemble the frame separately, and then lay it in finished form. In addition, over the entire area of the base there is a reinforcing mesh of rods with a diameter of at least 10 mm and a cell size of 15 × 15 cm.

- Arrangement of floor heating system. The technology of installation of UShP-foundation provides for the installation of a heated floor directly into the base plate. Due to this, the first floor of the building does not require additional heating. According to the design of the pipe is placed on the reinforcing mesh and fixed on nylon clamps. As for the collector, it is arranged in the base pillow height indicated in the drawings. In places where pipes will rise to the collector, corrugated protection is additionally mounted.

- Pouring concrete. The process of concreting can be started only in the case when all the above steps have been completed. Concrete brand is selected in accordance with the construction project. To simplify the pouring a special concrete pump or concrete mixer truck will help. The solution is evenly distributed over the entire basement area, ensuring that hard-to-reach places do not get empty.Concrete is recommended to use svezheprigotovlenny, at the end of the pouring work joints moistened with water and treated with a primer.

Summing up, we can say that the installation of UWB-foundation is not particularly difficult, but in order for the foundation to be strong and reliable, each of the above steps should be carried out strictly adhering to technology, and do not forget to do quality control.

If all norms of construction are observed, then the foundation of UWB will become a warm and strong support for the house.

Tips

Recently, in the construction of new buildings, they are trying to apply innovative technologies - this concerns not only the construction of the framework, but also the foundation. Most developers choose Swedish panels to install the base, as they have excellent performance characteristics and have positive reviews. Erecting such a foundation, it is worth considering some of the recommendations of experts.

- To begin work it is necessary with design. For this, the building plan is determined, the material for the roof and walls is chosen, since the load on the foundation depends on these indicators.It is also important to calculate the width of the foundation under the bearing walls. It is best to entrust the design to experienced professionals, but if you have personal skills, then you can handle it yourself.

- During installation, it is important to pay attention to the correct placement of the plates, especially in those cases where the material has not a rectangular, but a complex geometry.

The smaller the number of joints in the base, the less the risk of leakage. Therefore, the ideal is the option in which there are no joints under the slab.

- To the cost of the subsequent decoration of the building were small, the surface of the future plates must be pre-aligned.

- The thickness of the Swedish plates is determined individually for each project, since it directly depends on the loads.

- An important point when laying the UWB foundation is the arrangement of the drainage system. If it is performed with errors, then there may be problems with the removal of groundwater.

- When installing the pipes in the foundation, it is necessary to lay several additional channels and cables. They will be useful in case you need to build a new communications system in the future.

- After installing a warm floor before pouring concrete, you must check the quality of heating. For this, the pipes are filled with water and crimping is performed. If the seal is broken, a leak will appear that will have to be fixed. The pressure in the system of warm floors should be in the range of 2.5-3 atm.

- After pouring the concrete, time is given for the foundation to solidify. As a rule, it takes no more than a week. Proceed to the further construction is possible only in the case when the surface becomes durable. In the hot season it is recommended to wet the concrete and cover it with a film.

- For concreting the base layer is best to choose concrete brand M300 - it guarantees a solid foundation.

- The base on completion of the work can be finished with any material, but the design looks like an artificial stone.

- You can not use this type of foundation for the construction of houses above two floors.

- For arranging the foundation, it is not necessary to dig a deep pit - it is enough to prepare a pit 40-50 cm deep. It is advisable to treat a prepared pit with chemicals - this will help stop the growth of vegetation.

Plates of insulation should be laid in a staggered manner - otherwise the combined joints will cause the appearance of cold.

How to lay the UWB foundation, see the following video.