Driving piles: types and subtleties of installation

The most important element of any building is the foundation. The choice of technology for its construction depends primarily on the characteristics of the soil, as well as on the type of building under construction. The most actively used in modern construction is a tape and pile variant of the foundation.

Special features

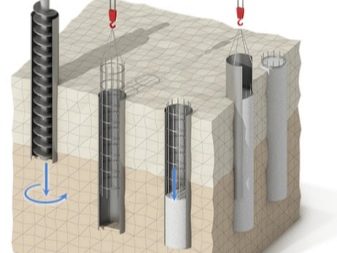

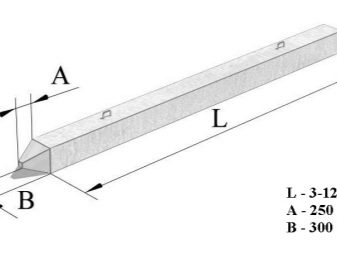

The foundation on driven piles, used in construction on unstable soils, has become widespread. For such a base, supports are used - reinforced concrete rods having a cross section (usually square) within 150-500 mm and a length of 3 to 25 m.

At the bottom they can be sharp for better penetration into the ground,and at the top - are equipped with a tip. The latter serves to protect the supports from deformation in the process of driving, hammer blows fall on the tip.

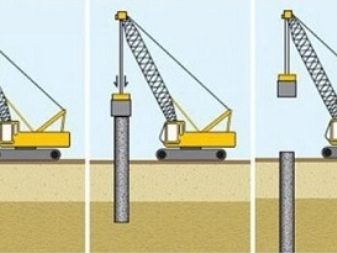

Piling in the ground takes place with the use of special equipment - a hydraulic hammer. The length and cross section of the pile are calculated based on the characteristics of the soil and the object under construction. The important point is that the length should be enough for the support to firmly rest on solid ground, bypassing the soft layers. Only in this case, we can talk about the stability and reliability of the object, not susceptibility to its influence from the heaving of the soil.

The scope of use of the foundation on driven piles is “problematic” soils — first of all, organic, that is, swampy, peaty soils. This type of base is suitable for clay and loamy, fine sandy soils, as well as water-saturated soils. Pile foundation can be used on uneven areas with height differences. In other words, the use of this technology makes it possible to make almost any soil suitable for construction.

It is worth noting that about 60% of the objects in our country are built in this way.

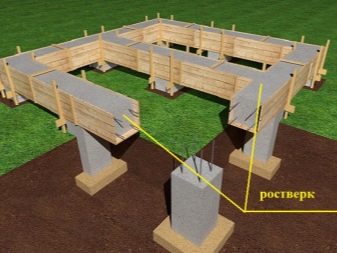

The foundation on piles can be tiled (grillage) or tape type. The first type is considered the best option for unstable soils.

Pile driving can be carried out using one of the following options:

- Pile field, usually used for the construction of high-rise plate-based;

- in a row - the piles are mounted in rows for low-rise private construction, while the supports are necessarily installed at the intersection of the bearing walls, at the corners;

- single supports, mounted in places prone to the greatest deformation of the soil.

pros

The main advantage of foundations on driven piles is the ability to carry out construction on almost any, including very unstable (peat) soils - where other systems are not applicable. The only exception for driving piles is rocky and permafrost soils, on which pile foundations are also carried out, but using a different technology (bored method).

Piles withstand not only vertical, but also horizontally directed loadthat allows you to apply them on the "swims". By adjusting the height of the piles at different points of the object, it is possible to conduct construction on the relief surfaces, slopes, areas with height differences.

Piles have a high bearing capacity, therefore they are suitable for the construction of both small buildings of private housing, and multi-storey residential buildings, civil, industrial and agricultural facilities. In this case, the supports have a long service life, which is 50-150 years.

The process of piling can be carried out year-round, implies a minimum amount of excavation work, as well as a high speed of driving - on average, a 4-m-long pile takes several minutes.

Minuses

Like any system, the foundation on driven piles has flaws. First of all, it is the impossibility to use such a method in the conditions of factory building or in case there are erected houses nearby. This is due to the fact that when driving, soil vibrations arise that are undesirable for the foundations of neighboring objects, as well as roads and main pipelines. In addition, the installation process is accompanied by a high noise level, which becomes a discomfort for people living in the neighboring houses.

Despite the conducted research and the construction of preliminary drawings, it is extremely difficult to predict how the soils will behave at great depths, so this technology does not preclude the risk of precipitation of the foundation and the violation of geometry.

Pile foundation does not allow to get a full basement or basement roomwhich can be exploited. If it is nevertheless necessary, then a pile-belt system with a dug trench is used, however this is a laborious and not always possible option. Finally, a drawback can be considered the need to attract special equipment, which will also entail additional costs.

The main regulatory document governing the construction process is the SNiP (Building Regulations and Rules). As for the design features of the bases on piles, they are set out in SNiP 2.02.03-85 ("Pile foundations"). The direct installation of the supports must comply with the requirements of SNiP 3.02.01-87 (“Earthworks, foundations and foundations”).

During the construction should be used reinforced piles, corresponding to GOST 1984-2012. Geological surveys (soil analysis, drilling of test wells) should be carried out according to GOST 19912.

Kinds

Depending on the material from which the driven piles are made, there are several types.

- Wood. Piles of wood have the smallest margin of safety, are used in private housing construction for light log houses or frame houses.The raw material used is larch, oak, cedar and other hard rocks, which are characterized by resistance to moisture and temperature changes. Structurally, they are supports with a diameter of 20-40 cm and a length of 3-8 m, usually equipped with a steel tip with strapping. Depending on the climate and operating conditions, the service life of wooden piles is at least 50 years.

- Steel. They have a slightly larger bearing capacity, but are also rarely used. As a rule, they serve as a support for temporary structures. A characteristic feature is the presence of a cone-shaped tip. Such a tapered metal pile resembles a screw analog, but does not have blades.

- Reinforced Concrete (ZHB). Received the most common, depending on the size can withstand a weight of 10-60 tons, the service life reaches 150 years.

RC piles, in turn, differ in the following criteria:

- depending on the method of reinforcement, there are pre-stressed longitudinal reinforcement (for sands, flowing sandy and clay soils), pre-stressed transverse reinforcement (for compressible, except clay, soils),longitudinal reinforcement without prestressing (for clayey, sandy soils), as well as piles with square cross section and a round cavity inside with prestressed or unstressed longitudinal reinforcement;

- shape distinguish piles with round, square, tee and hollow sections, as well as cylindrical and prismatic;

- based on the design, emit monolithic and prefabricated piles (composite);

- depending on the peculiarities of the heel, piles with a bound or hollow heel, and relatively recent piles with a broad base.

In addition, there are piles, columns, the aerial part of which acts as the columns of the building on the objects in one floor. The construction of such structures cannot be conducted on weak (peaty, silty), as well as large gravel soils.

Dimensions and calculation

To ensure the reliability of the foundation allows accurate calculation of the number of piles, the diameter of their section and length. When building a residential house, depending on the type of soil, reinforced concrete piles with a cross section of 150-250 mm in length from 3 to 10 m are used. As you know, piles should be supported on solid layers of soil - their length depends on it.

By drilling a geological well, soil features are established, and the depth of solid layers is determined. To calculate the number of supports you need to know the mass of the house. For example, the depth of solid layers on loamy soils averages 3.5 m, so the length of the piles will be 4 m.

To calculate the weight at home, you need to know how much 1 cu. m of the material from which it is built. In our case it is larch, 1 cu. m which weighs about 800 kg (this parameter allows you to find a special table, which can be found in the public domain for various building materials). The total area of the house is 60 sq. M. m. The total weight of the object is calculated by the product of these indicators. The result is 50 tons.

To this weight should be added the weight of the grillage, floors, finishing and other materials. Calculating by volume, we get another 80 tons. Add 10 tons of furniture and equipment used in the house during operation.

Add up the resulting figures, it turns out 140 tons. About 30% of the weight is laid down additionally for durability, so the total weight of the house will be equal to 182 tons.

A pile 4000 mm long, depending on the type of soil, can withstand a load in the range of 10-40 tons. If we take the average value of 20 tons, then the construction of a wooden house of 60 square meters.m will need 9 piles.

In practice, their number may vary slightly, since under the wooden and frame houses on the grillage the distance between the piles is set at 2-2.5 m.

After calculations are made, a pile driving scheme is drawn up. They must fall at the corners of buildings, at the intersections of bearing elements.

The pile section also determines its strength and bearing capacity. For example, a pile with a section of 150x150 mm is recommended for seasonal buildings, baths. Analogue with a section of 200x200 mm can be used for the construction of single-storey wooden or frame houses. For more impressive objects in 2-3 floors, as well as made of building blocks or bricks, supports with a section of 300x300 mm are required.

Installation

Installation of the foundation on driven piles begins with conducting geological surveys, during which the type of soil is established. On the basis of the obtained data, project documentation is created, materials are purchased. Directly on the construction site, the installation begins with its clearing and marking, the supply of materials. When marking the site, the pile driving points are also noted, after which the level and geometry of the future foundation is checked.

The technology of driving involves the use of special equipment with pneumatic or hydraulic hammer. The pile is installed strictly vertically and hammered into the ground with a hammer, plunging deeper and deeper with each blow. It is important to monitor the behavior of the support - it can stumble on a stone or some other solid formation or literally start “sinking” in the soil (it falls into the underground voids).

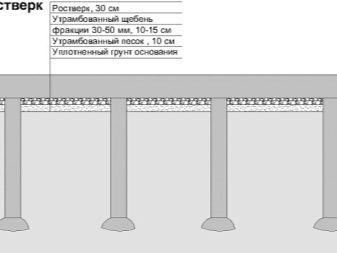

In this case, the support is extended or transferred 0.5-1 m further. When all the piles are clogged, proceed to beating the tops of the support to gain access to the reinforcement. The latter are aligned at the same height. After that the grillage is established, or the timbering for a strip foundation is being prepared. In the latter case, the formwork is reinforced reinforcing cage and filled with concrete solution. After he gains strength (after about 28 days), you can proceed to further work.

Rostverk, which is a monolithic slab that binds all the supports together, can be metal or reinforced concrete. In the first case, these are finished products of metal-roll, installed over the supports and welded to the rods of the reinforcement. As a rule, this type of grillage is used for small buildings (porches, baths) and temporary facilities.

For capital residential buildings use a reinforced concrete slab, which is obtained by pouring concrete with pre-installed formwork.

Depending on the type of construction, the grillage is of the following types:

- Hanging - in this case, the stove is located high above the ground, and the space under the floor is not insulated (suitable as a base for baths, attic, seasonal cottages);

- shallow-depth - plunges to a shallow depth in the ground, which, however, does not make it an additional support, but reduces the underground space of the structure from the weather and cold winds;

- buried - by analogy with a tape base, it is immersed in the ground, due to which, like piles, it takes up the load of the building (it is usually used for capital residential buildings).

Tips

After pouring the tape base or reinforced concrete grillage, the concrete must be protected with a covering material from the negative impact of the environment. In the hot season it is important to protect the surface from drying out; in the first week it is necessary to moisten the concrete as needed.

It is better not to pour the solution in the cold season, but if you still have to do it,This should be added to the composition of special components, as well as apply heating cable during the freezing phase of the solution. For mixing the solution, you should use cement, the brand strength of which is not less than M500.

During the pouring process, the formation of air bubbles in the solution should be avoided, since they reduce the surface strength. For this purpose, immersion vibrators are placed in the formwork, where the composition is already located, which compact the solution.

What is the foundation of driven piles, how it differs from others and how much it costs, you will learn from the video below.