Foundation casting: step-by-step instructions for construction

Filling a solid foundation requires a large amount of concrete mix, which can not always be prepared at once. Construction sites use a concrete mixer for this purpose, but in a private house, not everyone can afford such equipment. In this article, we will consider step-by-step instructions for self-pouring the foundation for a private room.

Special features

For the manufacture of concrete used cement and auxiliary components (gravel, expanded clay, sand). Water helps to improve the fluidity of the solution, and plasticizers and additives are added to the mixture to protect against severe frosts. Pouring a liquid mixture into a form (formwork) implies the beginning of irreversible processes in concrete, namely: setting, hardening.

During the first process, the solution turns into a solid state, because water and its components interact with each other. But the connection between the components is still not strong enough, and if the load is applied to the building material, it may collapse, and the mixture will not re-set.

The duration of the first process depends on the temperature of the environment and the moisture content in the air (from 4 to 24 hours). Reducing the temperature increases the setting time of the concrete mix.

The second workflow is hardening. This procedure is quite long. On the first day, the concrete hardens rapidly, and on subsequent days, the rate of hardening decreases.

You can fill the foundation with your own hands in parts, but you need to follow certain recommendations:

- Sequential mixing of concrete mix. If the interval between pouring does not exceed 2 hours in the summer and 4 during cool weather, no seams are formed, the concrete becomes as strong as with continuous casting.

- During temporary interruptions in work, it is allowed to perform flooding in no more than 64 hours. At the same time, the surface must be cleaned of dust and debris, cleaned with a brush, thanks to this, the best adhesion is ensured.

If we take into account all the features of the maturation of the concrete mix and follow important rules, then pouring the foundation in parts will not cause any particular hassle. The second layer of concrete is poured, not exceeding the time interval:

- 2-3 hours in summer;

- 4 hours if the work is done in the off-season (spring, autumn);

- 8 hours when pouring occurs in winter.

By filling the foundation with parts during the liquid phase of setting, the cement bonds are not broken, and when fully cured, the concrete becomes a monolithic stone structure.

Scheme

Before you start pouring the foundation, familiarize yourself with the technology for performing this procedure. There are two of them:

- block;

- layered.

During the construction of the floodplain foundation and the device of the underground ditch, the formwork is poured on the ground.

In this case, the casting is performed in compliance with the joints, that is, in layers. When building a monolithic foundation, pay attention to the block fill. In this case, the seams are located in a perpendicular position to the joints.This pouring procedure is suitable if you decide to make a ground floor.

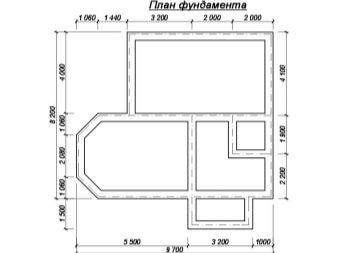

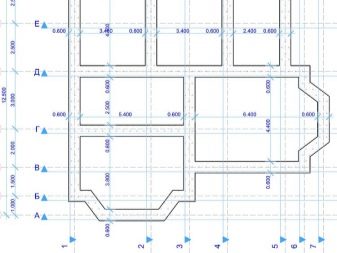

Before starting work, it is necessary to draw up drawings in the form of a large foundation scheme, on which the total area of the foundation is indicated, or it is divided into several areas depending on the technology chosen.

Based on the division into sections, 3 variations of the scheme are distinguished:

- Vertical split. The base of the foundation is divided into separate sections, which are divided by partitions. After 100% solidification, the partitions are removed and the concrete is poured.

- Oblique variation fill. Complicated method, which involves the division of territory diagonally. To perform it, certain skills are required, it is used in complex super-structural foundations.

- Horizontally partial flooding. The foundation is divided into sections in depth, between which no partitions are placed. Determined by the height of the application of each layer. Further pouring is carried out according to the scheme and time of introduction of a new portion of the mixture.

Training

The technology of pouring the foundation under the house requires careful preparation. Before construction starts, the markup is performed.The limits of the future foundation are determined by means of improvised means: reinforcement, rope, pegs, twine. By means of a plumb line, 1 angle is determined, after which the other angles are determined perpendicular to it. By applying a square, you can set 4 angle.

Pegs are driven in along the marked corners, between which the rope is stretched and the placement of the axis of the room is determined.

The same method can be used for internal marking, and you need to retreat from the external line by 40 centimeters.

When the marking is done, you can begin to determine the difference of elevated surfaces on the site. To measure the depth of the foundation, you need to start at the lowest point of the entire territory of the future cast. For small private premises fit depth of 40 centimeters. Once the pit is ready, you can begin to prepare it.

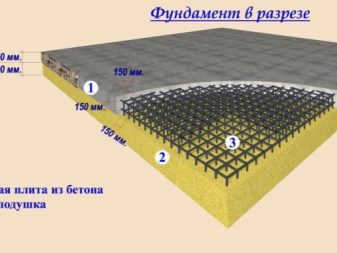

Before pouring the foundation, a sand cushion is laid on the bottom of the excavated pit, which is designed to reduce the load. It is distributed over the entire area of the site with a thickness of at least 15 cm. Sand is poured in layers, each layer is compacted and filled with water.As a pillow, you can use crushed stone, but its layer should be less than 2 times. After the bottom of the pit is covered with waterproofing construction materials (polyethylene, roofing material).

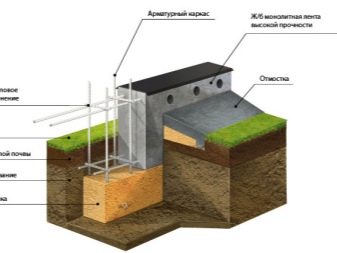

Now you can begin to install the formwork and reinforcement. This is necessary for greater durability of the base of the room and auxiliary protection against shedding of the trench walls.

The height of the formwork should be 30 cm more than the edge of the trench.

Installed fittings should not touch the ground, otherwise rust will appear.

The shields are installed along the very edge of the contour and are connected with jumpers made of timber. Such lintels hold the formwork in a vertical position. The lower edge of the boards must fit snugly to the ground so that the mixture does not flow out. From the outside, the guards are supported by props made of uneven bars, boards, reinforcing bars. But first you need to make sure that the walls of the formwork are located in a vertical position.

The armature is a large lattice with rectangular cells (30x40 cm). It is necessary to connect reinforcing rods with wire, not with welding. The latter option can lead to rust in the joints.In case the foundation is composite, you first need to fill the holes for the support columns and insert 3-4 bars of reinforcement inside which are interconnected.

The rods should rise not less than 30 centimeters above the bottom of the trench.

How to pour?

When purchasing concrete, pay attention to the products under the brands M-200, M-250, M-300. Basically, the construction of private premises and structures implies that it suffices to use a small-sized concrete mixer. In it, the concrete mix acquires the necessary consistency. The mixture to be poured is easily distributed in the inner area of the formwork, as well as carefully fills the air gaps.

Experts do not recommend pouring the foundation in rain or snow.

In some cases, construction is done in spring or autumn, when short-term precipitation falls. For this period the formwork is covered with special material.

Before embodying concreting, it is necessary to calculate the consumption of a mixture of concrete over the entire area. Since the base consists of several tapes, you first need to know the volume of each tape, and then fold it all up. To calculate the volume, the width of the tape is multiplied by its length and height. The total volume of the foundation is equal to the volume of the concrete mix.

Concrete preparation:

- sand is screened;

- mixing sand, rubble and cement;

- adding small amounts of water;

- thorough mixing of ingredients.

The finished mixture has a uniform structure and color, the consistency should be thick. To check if the kneading is done correctly, when turning the spade, the mixture should slowly slide from the tool with the total weight, not dividing into pieces.

It is necessary to fill the formwork in layers, distributing the solution around the perimeter, the thickness of which should be about 20 cm.

If you immediately pour the entire mixture, then air bubbles are formed inside, which reduces the density of the foundation.

After pouring the first layer, the mixture must be pierced in several places by means of reinforcement, and then compacted with a building vibrator. As an alternative to the vibrator, you can use a wooden rammer. When the surface of the concrete is leveled, you can start pouring 2 layers. The solution is again pierced, tamped and leveled. The final layer should be located at the level of the tensioned rope.The walls of the formwork knock with a hammer, and the surface around it is smoothed by means of a trowel.

Final stage

It takes a long time to 100% solidify the concrete mix, mostly it takes about 30 days. During this time, concrete gains 60-70% of its strength. When the curing procedure is over, it is necessary to remove the formwork and waterproof it with bitumen. Upon completion of the waterproofing works, the basement sinuses are covered with earth. At this the process of pouring the foundation ends, the next procedure will be the construction of the walls of the room.

How much should the foundation be laid after pouring, each specialist has his own opinion on this matter. It is usually considered that the foundation needs 1-1.5 years to recruit the necessary properties. But it is believed that the laying of bricks can be carried out immediately after casting.

Some builders recommend to carry out the construction of the foundation in the autumn, because during this period it will suffer all adverse conditions (frost, rain, temperature fluctuations). A foundation that has suffered such aggressive conditions is not in danger of anything further.

In any case, you must comply with the deadlines for upholding the foundation, and non-compliance with the rules will lead to disastrous consequences.

Tips

If you plan to repair the old foundation under a standing house, you need to determine the cause of the destruction of the foundation. Often, problems with the foundation arise from the fact that the owners choose a cheaper construction method. Remember, the building needs a reliable support, so that all components of the structure will last a long time.

If this rule was not followed, you will have to correct the error. It is necessary to reinforce the foundation so that, due to small cracks, the entire building does not collapse in the future.

Serial technology of work:

- Through the perforator, holes are punched through the center of each crack (40 cm deep) into which metal pins are installed. The diameter of the pins should be such that they fit tightly into the micro holes.

- By means of a hammer, the pins are pushed into the foundation so that the end of the tool is 2-3 cm left outside.

- Perform formwork, pour concrete with high quality concrete and leave for full hardening.

- Bury trenches, tamping the soil around the foundation as much as possible.

If you decide to replace the old foundation with a new concrete cast under a standing house, then you need to have specialized tools to lift the building. In this case, similar filling of the tape foundation is applied.

Basement insulation

If the foundation is built in the autumn period, in order to protect the solution from low temperatures, it must be insulated. Nothing is added to the concrete mix, the consistency of the mortar is prepared the same as for pouring in the summer.

For thermal insulation of concrete using various building materials:

- tol;

- polyethylene film;

- tarpaulin.

In severe frosts, concrete is sprinkled with sawdust, which perfectly fulfills the protective function of frost exposure. But it is also necessary to perform a slope so that the melt water does not remain on the building material, but flows from it.

Recommendations for the construction of a filler foundation:

- For the preparation of the concrete mix, it is recommended to use clean water, and gravel and sand should not contain clay and earth.

- The manufacture of high-quality concrete mix is a very important step,therefore, the ratio of ingredients should have the correct proportions, and also correspond to 55-65% of the weight of the cement mixture.

- The construction of the foundation in the cold season allows the use of warm water for mixing the solution. Warm liquid accelerates the process of hardening of concrete. If construction is carried out in the summertime, then only cool water is needed for the dough. Thus, it is possible to avoid the accelerated setting of concrete.

- 3 days after pouring the concrete mass, the formwork must be removed. Only when the concrete has gained sufficient strength, you can begin to build the base.

Foundation construction should be given special attention and be treated with great responsibility, because a well-made foundation is a good foundation for future construction.

To dismantle a poor-quality foundation is an almost impossible task, and with a poor-quality base there is a risk of damage to the entire room.

For information on how to do the pouring of the foundation with your own hands, see the video below.