Black silicone sealant: characteristics and application

Sealant is a material used to fill cracks and impermeability. For the correct choice of hermetic composition it is necessary to figure out exactly where it will be applied.

In general, sealants can be divided into silicone, acrylic and polyurethane. Which type to use in each particular case depends on a number of factors, such as temperature fluctuations, external influences, compatibility with the surface material and others. We will consider silicone sealants.

Kinds

Due to the elasticity of the silicone can not be coated with paints and varnishes, but this is offset by a fairly wide range of colors. There are clear, black and colored silicone sealants.

Hermetic agents can be divided into two groups.

- Single component formulations do not require additional action. They are completely ready for use, so they are widely used in everyday life.

- Two-component sealants consist of a basis and a hardener which are in different vessels. They give a reaction only as a result of mixing. Apply them mainly in industry.

One of the one-component sealants is silicone. It can be acetate and neutral.

In the first case, the material contains acetic acid, and in the second, alcohol. Due to this, acetate sealant should not be used with metal, stone and concrete, as the acid can have a negative effect on them. Neutral sealant easily cope with these problems.

Main characteristics

Due to chemical inertness, neutral silicone sealant can be used in various fields. It interacts well with metal surfaces and glass, is used at the joints of concrete and cement structures, used in shipbuilding and aviation.

Black silicone sealant is an indispensable tool for technical work with cars. The scope of its application in this direction is quite wide.

The structure is waterproof, well maintains various automobile liquids.

The only exception is gasoline, its impact on the treated surface may adversely affect the properties of the material.

This type of sealant is well resistant to short-term exposure to high temperatures, which can reach 300 degrees. When applied, it does not flow, is characterized by reliability and durability during operation.

You will learn more about the characteristics of silicone sealant by watching the following video.

How to choose?

Experts say that the quality of the sealant depends on the amount of silicone in its composition. The best is considered one hundred percent silicone composition. It does not shrink, has a long service life and is excellent in mechanical loads. The downside of this material is its relatively high price.

Introduction to the composition of silicone sealant additives can reduce its hermetic propertiestherefore it is worth choosing composition with the minimum quantity of additional components. You can determine the amount of additives by weight of the product. A package of 85 g pure silicone compound should not weigh more than 95 g. If the weight is greater, it means the presence of fillers.

It is also useful to determine whether a solvent has been added to the composition. This is detected by applying silicone onto polyethylene. If the composition is clean, the surface under it will not grimace and inflate.

Features of work

Working with black silicone sealants does not cause any special problems:

- for convenient putting sealant it is worth using a special gun;

- after opening the package, the dispenser is put on the remote tip of the spout, which must be cut off depending on the required volume of the supply of funds;

- it is necessary to remove dirt and dust from the surface, process it with a sealant, and also dry it thoroughly;

- excess silicone should be removed from the coating before it hardens, after which it can be cleaned only by mechanical means.

Features and Overview

One of the most popular silicone sealants is Sikasil SG-20.It is used to repair and create tightness during construction.

Sealant Sikasil SG-20 is used for fastening elements of the facade, filling joints and cracks. It is well established as a composition for window structures and structural glazing.

The material is packaged in containers of 310 and 600 ml, as well as 20 and 200 liters. It is ready to use, does not contain solvents, practically does not shrink. Temperature during operation should be from 5 to 40 degrees above zero.

Sikasil SG-20 glue works well with almost all types of surfaces.It is characterized by moisture resistance and withstands adverse weather conditions. During application, the sealant does not sag, is durable, well tolerates exposure to ultraviolet rays and has an anti-corrosion effect.

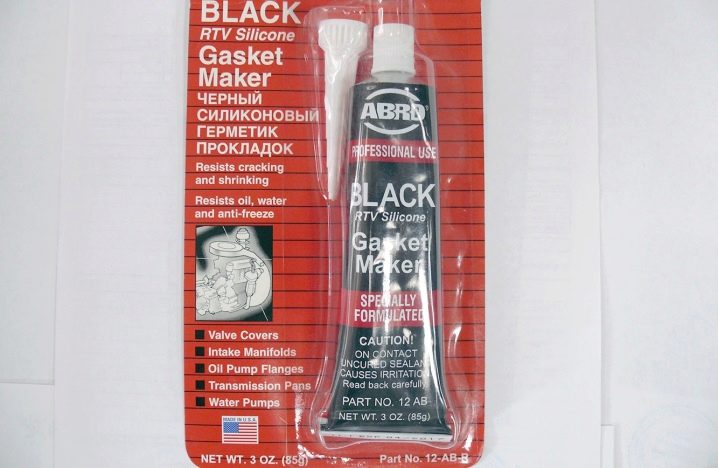

Another popular brand is black silicone sealant Abro.designed to repair gaskets in car engines. It is well tolerated by the impact of specific automotive fluids, except gasoline. With it, you can work with a water pump, valve cover and transmission tray.

High-temperature sealant can withstand temperatures up to +340 degrees, has anti-corrosion effect and has virtually no odor.

Permatex Black Silicone Adhesive Sealant black silicone adhesive sealant contains synthetic rubber, which helps to withstand temperature fluctuations from –60 to +260 degrees, does not shrink or crack during operation. The treated surface is elastic, but at the same time it is airtight.

This material can be applied both on vertical and horizontal surfaces. It firmly withstands the effects of water and is non-toxic. Glue-sealant has a good hitch with a variety of basics, such as glass, wood, ceramic and metal surfaces, plastic and others. Full hardening is carried out in a day. The sealant maintains contact with automotive fluids.