Frost-resistant and waterproof outdoor sealant

Sealant for exterior work is used to seal joints and seams, window openings. For building facades, only those products that are resistant to high humidity and temperature extremes can be used. The modern market offers a huge selection of sealing means.

Special features

Silicone sealant is excellent for performing complex and delicate exterior work. This product is absolutely safe for both the environment and human health.

It has the following specifications:

- elasticity, so that the sealant effectively and quickly fills all cracks and gaps;

- high level of strength, which allows for the most difficult external work in conditions of intensive use;

- resistance to sudden changes in temperature;

- high adhesion level;

- resistance to low temperatures and high humidity.

The composition of this product has plasticizers, dyes and various additional fillers. Experts recommend choosing a material with an optimal ratio of price and quality, because cheap additives make the sealant unstable to environmental influences.

Often in stores you can find sealants placed in plastic cylindrical packages with an unfixed bottom. Also there are products placed in a disposable foil tube of a certain volume.

Kinds

There are a lot of sealants. The qualification is based on the type of composition.

- Silicone sealants are elastic, waterproof, and also resistant to temperature extremes. The composition of rubber, so that such a rubber sealant is durable and safe.

- Acrylic options presented in different colors, in their composition there are acrylic polymers. Water resistance of the product provides the ability to use for work on the street. In order for this sealant to "show" all its advantages, it needs dryness and warmth.Complete drying of the composition is carried out after 24 hours.

- Polyurethane models are durable, resilient, resistant to mechanical stress. They are suitable for working with different materials, do not emit toxic substances, and are also susceptible to staining.

- Bituminous Sealants made from bitumen polymers, which are obtained as a result of the processing of residual oil products. They can even be used in drainage systems, as they are moisture resistant. The basis of brown bituminous sealant laid rubber and bitumen. Transparent formulations are also offered, which are more expensive, but they are suitable for all materials.

- Butyl options designed for sealing glass.

Adhesive sealant can be presented in different colors:

- white - used for plumbing and window profiles, as well as for sealing cable ducts;

- transparent - used to work with wooden windows;

- Black is an outdoor product, resistant to sunlight, suitable for facade and roofing works, and also often used for vehicle repairs;

- brown - suitable for sealing various brown materials;

- color - used for plumbing and windows, but you can pick up the product of the desired shade.

Depending on the properties of the sealant is divided into several types.

- frost-resistant - designed to seal joints at low temperatures. This is a “winter” product that can be used even in extreme conditions with sub-zero temperatures;

- moisture resistant - designed for operation in wet areas, for example, a bathroom or kitchen;

- heat resistant - heat resistant product that is suitable for sealing elements of furnaces, heating systems, and so on. It does not deform under the influence of high temperatures and retains its properties.

Scope of application

Sealants have been applied in different situations. When building buildings, no matter how hard you try, you will not be able to avoid gaps in the seams and joints. That is why for their finishing use sealants.

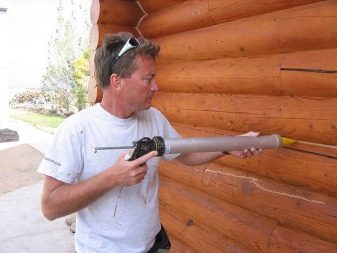

For houses made of wood at the joints outside, it is necessary to use an elastic product.which can stretch and take the original form.If the facades are not hidden under any finishing material, it is important that the seams are neat and even.

When sealing walls made of concrete or brick, as well as metal objects, you should take care of high-quality adhesion to the surface. Sealants used for these works must be resistant to temperature changes, ultraviolet radiation and high humidity. Polyurethane sealants are ideal for panel buildings and facade seams, which allow you to quickly achieve the desired effect.

There are even more requirements for roofing sealants. They must be reliable, high-quality, withstand various weather conditions. Appearance in this case is completely unimportant, so you can safely use bitumen sealants, which are only black. Also for roofing rubber sealants are used. They are also suitable for sealing the elements of the drain, sites removing antennas, chimneys and so on. This product is used both during the construction of the building and during the repair of the old roof.

It is impossible to do without sealants in the work with openings for doors and window frames.When buying a sealant for the foundation, attention should be paid to such properties as reliability, resistance to temperature extremes and chemical aggressive agents.

Consumption

Before work, it is necessary to calculate the approximate consumption of sealant in order to purchase the required amount of the composition. To do this, determine the width and depth of the crack that you intend to seal. This indicator is influenced by the depth of the joint and the material from which the object is made. The depth is multiplied by the width, all this is calculated in millimeters. The result is the product consumption per 1 m joint in grams.

If the joint is triangular, the result can be divided into two, because the costs of the composition are significantly reduced. This is inherent in perpendicular surfaces, for example, for sealing the joint between the bathroom and the wall. If it is necessary to seal the crack, the material will need more.

Consumption composition per meter depends on the material of the object. As a rule, during construction a standard value of this indicator is established, it is often equal to 6 mm, but there are exceptions. If the size of the seam is larger, a silicone cord is used as a seal.This option is suitable for wooden surfaces.

Sealant is sold in stores in different containers. To select the necessary packaging, you must first perform the calculations. For example, 0.25 kg of material is required to seal the seam on a 10-meter surface.

The assortment of companies has tubes with a volume of 0.3 kg - this is an excellent choice for the planned amount of work.

To buy a sealant was enough for the entire surface, it must be applied according to the established rules:

- pre-prepare the object, degrease it and clean the garbage;

- masking tape is glued to the area where the silicone will be located on both sides, which will prevent material from getting on a clean surface;

- tube with the composition is inserted into the construction gun, pour it into the seam, after which the mixture is leveled with a spatula.

Tips and tricks

The first problem faced by those who started repairs is the choice of a reliable sealant. The most popular are polyurethane and silicone compounds. The first option has many advantages, it has proven itself in working with external walls.But keep in mind that it is unstable to ultraviolet. Silicone sealants deserve a lot of positive feedback, but the cost of them under the force is not for everyone. If you live in a warm region, you can choose a bituminous sealant.

Experts recommend using this composition to work in the attic or roof, it can also be used for drainpipes, drainage systems.

Often buyers find it difficult to choose - domestic or foreign products. Today, there is practically no difference between goods, domestic companies use the same technologies and components as foreign ones. But the price of sealants differs greatly, since the cost of foreign goods includes transportation costs. Experts advise buying sealant in large stores where you can compare prices, study the formulations and even check the weight of the goods, because sometimes the same containers have different weights.

For professional use offer a product in tubes, the application of which is performed using a special gun. It allows dispensing material and speeds up the sealing process.For small works designed household tubes.

For high-quality sealing of seams and cracks it is recommended to observe the following rules:

- places for future sealing must be pre-processed, cleaned of dust and the old coating;

- if outdoor work is carried out in winter, the area must also be cleared of snow and frost;

- to increase the adhesion, the edges of the seams must be primed;

- if the crack is too deep, it is necessary to apply an anti-adhesive gasket, which will significantly save sealant;

- in order to save sealant, it is best to use a mounting gun or pump. The first tool is suitable for sealing small joints;

- outdoor work should not be performed during precipitation, as well as under freezing conditions. If this is not to be avoided, it is better to entrust the matter to experienced specialists, since in this case you will need professional tools and drawing up an act of sealing;

- make sure the sealant is snug against the wall material;

- in adverse weather, the process of drying the sealant may take more than one day.

Sealants are durable. To get a good result, you should not buy the cheapest formulations. After completing a quality sealant application, you will forget about cracks for a long time.

On what kind of sealant is better to choose, see the next video.