Polyurethane Sealant: Pros and Cons

Polyurethane sealants are in great demand among modern consumers. They are simply irreplaceable in cases when it is necessary to seal a variety of materials with high quality and reliable. It can be a tree, and metal, and brick, and concrete. Such compounds are both sealant and glue at the same time. We will get to know them better and find out what pros and cons are inherent in them.

Special features

Until the middle of the last century, various compounds were sealed with rubber or cork. At that time, these materials were quite expensive and people were looking for more affordable alternatives.

The first experiments on the synthesis of polyamides started in the USHowever, the success of this case was achieved by German scientists, who also took part in new developments. So there appeared popular today materials - polyurethanes.

Currently, polyurethane sealants are among the most common and sought after. Such materials are sold in every store building and finishing materials, which indicates their availability.

Most buyers choose precisely polyurethane compositions, since they have many positive qualities.

Let's look at some of them:

- Polyurethane sealant has a high elasticity. Often it reaches 100%. Working with a similar composition is very easy.

- Such mixtures can boast excellent adhesion to many types of materials. They fall seamlessly on concrete, brick, metal, wood and even glass. In addition, a good self-adhesive is also inherent in polyurethane sealants.

- Such compounds are wear resistant. They are not afraid of high levels of humidity or aggressive ultraviolet rays. Not every binding material can boast of such characteristics.

- Polyurethane sealant can be safely chosen also because it copes well with its main task.This mortar ensures excellent sealing and waterproofing of the necessary parts for quite a long time.

- Also, polyurethane sealant is not afraid of temperature changes. It seamlessly transfers the effects of sub-zero temperatures down to -60 degrees.

- Such a composition can be used at any time of the year. For example, it may be winter with cold ambient air. In such conditions, the sealant will still easily fall on this or that basis, therefore, repair work will not have to be postponed for a warmer period.

- Polyurethane sealant does not form smudges. Of course, this property takes place in cases where the applied layer does not exceed 1 cm in thickness.

- This composition gives minimal shrinkage after completion of the polymerization.

- Polyurethane sealant is also convenient because it dries in the shortest time and hardens pretty quickly.

- Sealant with a polyurethane base can be painted in any color or be colorless.

- It is worth noting the environmental friendliness of modern polyurethane sealants. These materials do not incorporate hazardous and harmful substances released by high temperatures.Due to this advantage, polyurethane sealants can be used without any fear in the arrangement of residential premises - baths, kitchens.

- If the air contains moisture, then under its action such a sealant will polymerize.

- Polyurethane compounds are not susceptible to rust.

- Such materials are not afraid of mechanical damage.

With external exposure, they quickly take the same shape.

It is worth noting that polyurethane-based sealant is similar in many respects to assembly foam during its drying, as it polymerizes in the shortest possible time and becomes solid.

In the composition of modern sealants there is such a component as polyurethane with a single-component structure. Also in the shops you can meet and two-component options that can boast improved sealing properties.

As you can see, there are a lot of advantages for such building mixtures. However, polyurethane sealants have their own weaknesses.

You should also familiarize yourself with them if you have to work with these materials:

- Despite the fact that polyurethane sealants have excellent adhesion properties, in some cases they are not enough.A similar problem can be encountered if you seal structures made of certain types of plastics.

- According to experts and manufacturers, polyurethane compositions can not be laid on the base, the moisture level of which exceeds the mark of 10%. In this case, they should be “reinforced” with special primers, otherwise you will not be able to achieve sufficient adhesion.

- It was stated above that temperature drops are not terrible for polyurethane formulations. However, it should be borne in mind that a long stay in a temperature of 120 degrees can lead to the fact that the sealant will lose its performance.

- Few people know, but the disposal of polymerized sealant is an expensive and very difficult operation.

Kinds

Thanks to a wide range of customers can choose the best option sealant for different conditions. Let us consider in more detail what types of such compositions exist today.

First of all, all sealants on polyurethane should be divided into one-component and two-component ones.

Single component

This sealant is quite common.It is a substance resembling paste in its consistency. In its composition there is one component - polyurethane prepolymer.

This adhesive sealant boasts high adhesion to most materials. It can be used even when working with capricious ceramics and glass bases.

After laying the one-component composition at the joints, the stage of its polymerization begins.

This is due to exposure to moisture, which is contained in the ambient air.

According to experts and craftsmen, one-component sealants are recognized as one of the most convenient to use. To obtain them, it is not necessary to combine different components, so as a result, the quality of the seams is always excellent. Such compositions are used both in repair and construction work.

Most often they are chosen for sealing:

- various building structures;

- roof joints;

- car bodies;

- glasses that are installed in cars.

The latter type of sealant is otherwise called glass. As a rule, it is used in the process of pasting automotive glass, as well as when installing fiberglass decorative items in cars.In addition, such a composition is indispensable if you need to glue elements of glass or plastic on a metal base, which is constantly subjected to vibrations, temperature changes and moisture.

Of course, one-component sealants are not ideal and have their drawbacks. First of all, you should know that it is impossible to apply them at temperatures below -10 degrees. This is due to the fact that in such conditions the level of air humidity decreases, and after that the polymerization of the material decreases. Because of this, the composition hardens longer, loses its elasticity and loses the necessary hardness. In addition, under such conditions, the one-component adhesive sealant becomes more viscous, so it becomes very inconvenient to work with it.

Two component

In addition to one-component, in the shops you can meet two-component sealants. In the packaging of such products there are two necessary components, packaged separately from each other:

- a paste containing polyols;

- hardener.

Until the moment these substances are mixed, they can be stored for a long time, since they do not collide with the external environment.

The main advantage of two-component mixtures can be called the fact that they can be used in conditions of low temperatures, because during their drying, the moisture present in the air takes no part in the process.

Using two-component compositions, the seams are also obtained qualitative and very neat.

In addition, such materials are distinguished by durability and increased strength characteristics.

There are two-component sealants and their disadvantages:

- They can be used only after thoroughly mixing the necessary components. This leads to an increase in the time you take to complete all repairs.

- When using a two-component composition, the quality of the joints will directly depend on how correctly the proportions of the necessary components were selected in the process of mixing.

- This adhesive sealant should be used immediately after mixing. It will not be stored for long.

If we compare one- and two-component formulations, then we can conclude that the former are more popular, since it is much easier to work with them, especially when it comes to domestic use.

For concrete

As for the construction field of application, it is often used a special sealing adhesive for working on concrete. It is distinguished by its composition - it does not contain solvents.

Many consumers choose a sealant designed specifically for concrete, as it is fairly easy to work with. In addition, with their use, the seams are of high quality and neat.

Polyurethane sealant for concrete is very often used for outdoor work, because it can be applied immediately, without losing time to prepare the composition.

With this composition, you can get rid of many deformation elements. For example, these may be noticeable cracks and gaps that have appeared in concrete floors over time.

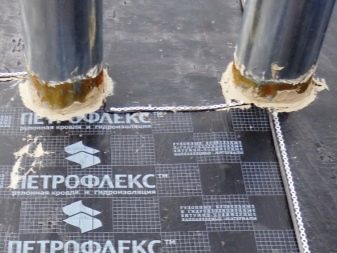

Roofing

This type of sealant is different in that its composition is based on a resin that is polymerised under special conditions. As a result, the result is still the same soft mass, which seamlessly falls on many materials.

Compositions with a suitable level of density are ideal for roofing. Thus, PU15 is well suited for general roofing, insulation of coatings, as well as processing joints of metal, wood and plastic.

Properties

Sealants on polyurethane are distinguished by the fact that they have excellent strength characteristics and have a long service life. They are not afraid of adverse environmental factors. They do well even under water, so you can use such mixtures in various fields.

As a rule, people use special cartridges that are simply put on (screwed) on the tip, cut off according to the desired diameter and inserted into a regular gun.

Polyurethane sealants seamlessly adhere to most known materials, for example:

- with brickwork;

- natural stone;

- concrete;

- ceramics;

- glass;

- a tree.

When open cavities are filled with a similar composition, it forms a very neat layer resembling rubber. He is absolutely not afraid of negative external factors. It is worth paying attention to the fact that high-quality polyurethane sealant is 100% interlinked with one or other bases, regardless of their texture.

After drying, the sealant can be painted. From this, he will not lose his useful qualities and will not undergo deformation.

Polyurethane sealant is a fairly economical material, especially when compared with different analogues. One package may well be enough to handle a considerable area. For example, if you need to fill a joint having a length of 11 m, a depth of 5 mm and a width of 10 mm, then you will need only 0.5 liters of sealant (or 2 cartridges of 0.3 liters each).

As for the average consumption of material with a seam width of 10 mm and a depth of 10 mm, it will be 1 tube (600 ml) by 6.2 p. M.

Modern polyurethane sealants are distinguished by a short drying time. However, we must not forget that this parameter is influenced by the density of the applied layer.

The composition on the basis of polyurethane seamlessly adheres to other sealants. Due to this property in the event of damage to the seal, you can easily repair the affected area. As a result, improvements will be almost imperceptible.

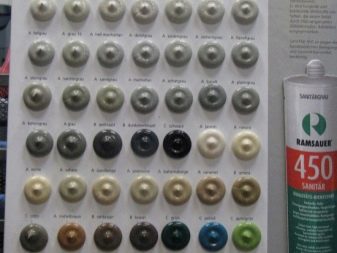

Polyurethane sealants are transparent and colored. In the shops you can find not only simple white ones, but also gray, black, red, yellow, blue, green and other colorful compositions.

Consumption

Polyurethane sealants have many positive qualities, which include the efficiency of their use.Many consumers are wondering how to correctly calculate the flow of such a composition.

Important input data in this case are the width, depth and length of the seam, which must be sealed. You can calculate how much sealant you need on a polyurethane basis using the following simple formula: weld width (mm) x weld depth (mm). As a result, you will learn about the need of the material in ml per 1 running meter of the seam.

If you plan to form a seam of a triangular shape, then the result should be divided by 2.

Application

Modern sealants on polyurethane are used in various fields, as they are easy to use.

Let's take a closer look, in which cases we cannot do without such adhesives:

- Such adhesives are used for both internal and external works. It is often used for high-quality sealing of door and window openings.

- This sealant can be used when equipping a new window sill.

- If you need to seal the seams remaining between the panels, then polyurethane sealant is best suited.

- Often, such materials are used in embedding structures made from natural / artificial stone. For such work sealant on polyurethane fits perfectly.

- Do not do without such compositions, and in case you need to handle objects exposed to light vibration, where the filled seams can be deformed. That is why these tools are used in the automotive industry. For example, they can be used to assemble and disassemble lights and glass.

- Polyurethane-based adhesive sealant can be safely used for high-quality waterproofing of the roof, foundation and artificial reservoirs, since it does not lose its positive qualities when in contact with water.

- Often these sealants are used in the assembly of various pieces of furniture.

- Polyurethane glue is used for sealing joints and in cases when the structure is under constant temperature extremes.

- The suture is often used in the assembly of wooden porches of different sizes.

- Polyurethane sealant is used for insulation of metal pipes.

- It is used to prevent corrosion.

Application Instructions

In the composition of one-component sealants on the basis of polyurethane there is only the main component. There is no solvent in them, so they are sold packed in 600 ml tubes in foil.In addition, in the shops you can find small containers of 310 ml in metal cartridges.

To apply such a sealant, you need to have in your arsenal a special gun.

There are several devices that are used to apply glue.

- Mechanical pistols. Such tools are most often used in private construction, since they can be carried out on a modest scale.

- Pneumatic guns. With such devices you can produce medium-sized work. Often, experienced craftsmen and professional brigades turn to such options.

- Rechargeable. Such devices are most often used in the construction of multi-storey buildings.

Before starting work on the gun, put on a special nozzle. In order for the quality of the processed weld to be high, its diameter at the sealant itself must be 2 times greater than the depth.

To begin with, it is necessary to remove dust, dirt, paint and any oils from the base to be treated.

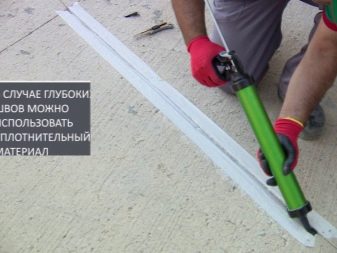

The seams between the blocks or panels are first insulated. Foam polyethylene or regular assembly foam is suitable for this.Polyurethane sealant must be applied over the insulating layer. To this end, experts recommend purchasing hand air guns or spatulas. Lay the mixture evenly so that there are no gaps or voids left. After applying a layer of sealant must be leveled. For this purpose, use wood or metal jointing.

After 3 hours after completion of all work, the sealant becomes waterproof and resistant to temperature changes.

Manufacturers

Today, there are many manufacturers that produce high-quality and reliable sealants based on polyurethane. Let's get acquainted with some of them.

"Moment"

This manufacturer is one of the largest and most famous. The range of the company is very rich. Moment offers not only sealants, but also adhesive tapes, various types of glue, chemical anchors, and tile products.

As for polyurethane sealants, it is worth mentioning among them the popular product Moment Germent, which forms a solid and elastic adhesive joint, which has a high resistance to water, household chemicals, oils, petroleum products, acids and salts.

This popular product is used for insulation and gluing materials in construction and industry. It easily clings to wood, baseboards and various decorative objects.

In addition, "Moment Germent" is used for stickers of roof tiles and skates.

"Izhora"

The Izhora Production Company is located in St. Petersburg and offers high-quality polyurethane-based adhesives for consumers to choose.

Izhora produces both one- and two-component compositions that can be used to seal joints on facades and plinths, in the treatment of seams and cracks in floors, as well as for external processing of door and window openings.

In addition, the company offers formulations with gray, blue, green, yellow, brick, pink and lilac colors.

Olin

This is a famous French manufacturer that produces high-quality polyurethane sealants. The assortment of the brand contains the popular compositions “Isoseal” P40 and P25, which easily fall on concrete, ceramics, glass, aluminum, steel and wood.

These polyurethane compositions are sold in 600 ml tubes and 300 ml cartridges.Olin polyurethane sealants are also available in a variety of colors: gray, beige, dark beige, dark gray, terracotta, orange, black, and under teak.

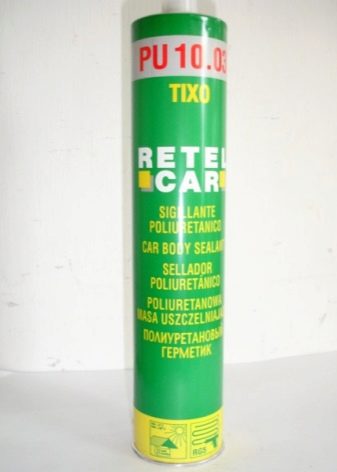

Retel car

Retel Car is a popular Italian manufacturer that produces polyurethane sealants, which do not drain and are well suited for processing vertical surfaces. They are used in automotive production, for sealing containers, when laying air ducts and air conditioning systems.

Sikaflex

The Swiss company Sika produces a range of high-quality products based on polyurethane. So, Sikaflex sealants are multi-purpose - they are used for roofing, when installing air conditioning systems, as well as when pouring deformations on concrete.

Also, Sikaflex polyurethane sealants are permissible to use when sizing windowsills, steps, baseboards, various facing elements. They have excellent adhesion and easily seize even with plastic.

Dap

It is a well-known US brand that offers silicone, polymeric and polyurethane sealants. The company's products are distinguished by affordable cost and good performance.For example, the popular composition “Dap Kwik Seal”, which is ideal for sealing joints in the kitchen or bathroom, can cost from 177 to 199 rubles (depending on the volume).

Tips and tricks

If you want to remove the sealant from a particular surface, then you should dissolve it. Special types of solvents for such compositions can be found in many hardware stores.

Some consumers are wondering how to dilute these sealants so that they turn out to be more liquid.

There is no universal recipe. Some people use white spirit for this, and others use gasoline.

Roofing compounds should not be used for interior work, as they are toxic.

Work with polyurethane sealants with glasses and gloves. If necessary, wear a respirator.

If, after applying, you notice that the adhesive layer needs an adjustment, then you will have another 20 minutes for this job while it dries.

For information on how to work with a polyurethane sealant in a tube, see the following video.