Clear sealant: pros and cons

Very often there are situations when there is a need to seal the seams to protect areas from moisture penetration. To minimize the risk of such problems, you should use a specialized tool. Silicone sealant will be suitable for this work, since it can be used to create a high-quality and waterproof connection between the surfaces.

Special features

Before the sealant was universally used in construction and repair work, all sorts of home-made putty and mastic were used. However, these tools were ineffective. New composition at times simplified the process, at the same time increasing its productivity. Sealant is a viscous tool with good density, intended for sealing cracks and joints, sealing seams and gluing together various components.Plus, the tool provides the treated base with excellent protection from moisture and a number of other phenomena that adversely affect the surface.

Universal clear sealant in its composition is a complex mixturecomprising a whole group of components. The presence of plasticizers provides the composition with elasticity, and vulcanizing agents are responsible for the viscosity of the mixture. The main component of the base is rubber, the primers provide adhesion of the composition to various surfaces, the filler is responsible for color, and the hardener affects the strength.

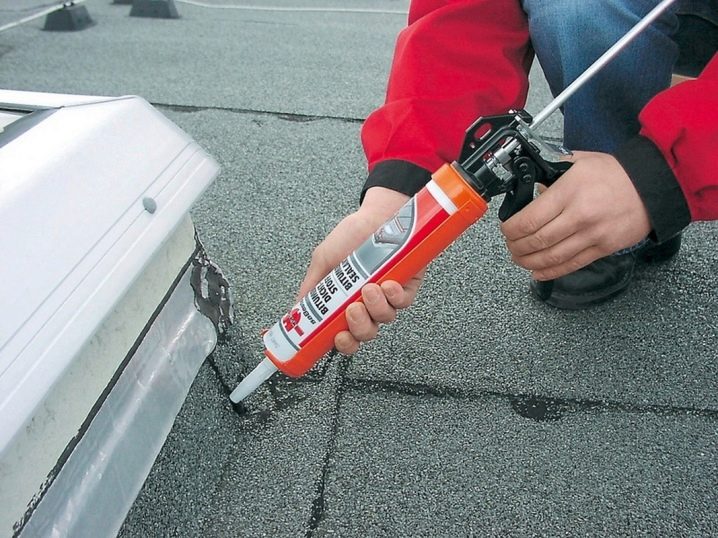

The composition is available in tubes that have special pistons for extrusion.

There are certain features inherent in these products, among which are the following:

- resistance to chemicals;

- good adhesion to different materials;

- resistance to ultraviolet and weather phenomena;

- good accommodation movement;

- thermal stability and excellent low temperature tolerance;

- Most of the compositions without problems can be used at temperatures from -30 to +60 degrees.

Silicone, like any other material, in addition to its advantages, has a number of disadvantages.These include the inability to use the product on a wet surface, as well as the occurrence of problems with the colouration of the sealant, if the composition contains insufficient organic components.

However, inertness to many substances and environmental safety of products make it possible to use sealant in everyday life, construction, mechanical engineering, as well as in medicine. The scope of application means directly depends on the additives that make up the composition, due to which it becomes inherent characteristics and properties.

Kinds

Silicone sealant is used for exterior and interior applications. It is indispensable for the installation of plumbing and kitchen furniture. In rooms with a high level of humidity, it is recommended to use a neutral sanitary composition that does an excellent job with the task of sealing joints near a shower stall, sink or glassware. To eliminate the blowing of window frames from wood can be due to the use of this tool intended for external sealing. Such products do not deteriorate from exposure to the surface of the sun's rays and perfectly withstand various temperatures.Colorless composition will be invisible on dark varieties of wood.

Since the silicone coating is difficult to paint, in some cases it is required to purchase colored products, for example, white, red or even black sealant.

Among the range of products there are special heat-resistant compositions.operating in a temperature range of -50 to +300 degrees. The tool is used in electrical work, in the assembly of industrial structures. For work with the roof there is a sealant on a bitumen basis, it perfectly seals cracks and other types of defects, the formation of which is possible on the roof, basement or foundation of the building. The tool is cold-resistant and well glues metals, plastic and wood.

Products are divided into two groups: two-component and one-component sealants, differing in scope.

Single-component tools are classified according to the base.

- Alkaline - composition is made on the basis of amines. This type is a specialized material.

- Acidic compounds, where the main component is acetic acid.Its smell is present during the curing of the sealant on the surface. The main disadvantage of the tool is incompatibility with a number of metals, because it provokes corrosion. It is not recommended to work with sealant on cement surfaces that have alkali in the composition.

- Neutral products are perfectly combined with all surfaces due to ketoxime or alcohol, which is part of.

When purchasing a product, attention should be paid to the presence of additives - it can be a dye, mechanical fillers, providing adhesion to the base, extenders that reduce viscosity, and fungicides that protect against the development of fungus and mold. The presence of such components greatly expands the use of products. The composition is perfectly stretched, due to which it can be applied to moving parts.

Having a number of advantages, the disadvantages of the funds still include the minimal adhesion to narrow polypropylene plastics, fluoroplastic and polyethylene.

Since the area of use of products is very diverse, types of sealants are divided according to their application.

- Special formulations are products designed to work in conditions of maximum humidity. Special sealants have good adhesion with non-uniform surfaces, and also withstand contact with aggressive cleaning agents.

- Construction sealants have high adhesion rates and are resistant to sunlight and humidity. With their help, they close up joints in the bathroom, in sinks, in batteries and pipes, they are also used as glue for decorative moldings or as a sealant for automotive lighting. Transparent "Moment" represents this type of sealant.

- Automotive products are purchased to replace automotive gaskets. It does not lose its properties when temporarily exposed to high temperatures, and is resistant to antifreeze.

Consumption

To count the amount of material required for sealing joints or other work, you need to know some features of the work, then it becomes clear how much you need to purchase material per 1 m² of surface. This is an approximate value of the width and depth of the gap.Sealant consumption is calculated using a fairly simple formula: the seam width must be multiplied by the depth, resulting in a calculated meter. For triangular seams, the resulting value must be further divided by two. As practice shows, a tube of silicone sealant with a volume of 0.3 kg can be filled with a composition of 10 m working area, having dimensions of 5x5 mm.

Manufacturers

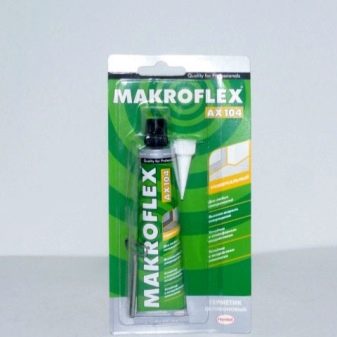

Finnish company Macroflex has extensive experience in the production of a variety of sealants and adhesives. She has millions of output on her account, since the production facilities have been manufacturing goods for more than thirty years. Universal silicone sealant of this brand is popular due to its high quality and excellent performance properties. Most professionals prefer to use such products in their work.

Soudal - is a company from Poland, which specializes in the manufacture of sealants, seals and glue. All products undergo quality control and are manufactured on modern equipment using the latest technology.Goods have a higher cost in comparison with Russian similar products, but the quality of the compositions justifies their high cost.

The brand "Moment" is a leader among similar products offered by Russian manufacturers. The company has been producing formulations for about 30 years, and during this time has established itself only from the positive side. All products are manufactured in Russia. Sealants "Moment" combine low cost and reliability. A bright representative of the products of this company is the frost-resistant sealant "Germent" with a volume of 280 ml. It is made on the basis of acrylic dispersion, durable and can be used for interior and exterior use. Sealant can be painted with any coloring composition. However, for sealing seams that will constantly in contact with moisture, it is not worth using.

Atoll Spheraflex 300 - This is a one-component transparent sealant. The products have good adhesion to glass, enamel, wood and metal, as well as painted surfaces, ceramics and materials that are not uniform in texture. The composition is recommended for sealing joints and slots, especially for elements with moving areas.

Widely popular sealant is used for work related to glazing loggias, greenhouses, winter gardens, for floor and tiles. It does not shrink after hardening, has a good indicator of heat resistance - from -40 C to +120 degrees. Very easy to use when working with a gun.

Tips and tricks

Like any other product, silicone sealant has a lot of analogues with a very low level of quality. This feature is directly related to the composition of the product, because it combines cheap components of organic origin, such as kerosene or oil, which have a negative impact on such quality characteristics - strength, moisture resistance, heat resistance and color stability. The service life of low quality products is much less than that of good quality materials. Therefore, in order to avoid all sorts of problems in the course of construction or repair work, it is necessary to buy sealants only from proven manufacturers who have proven themselves in the market.

If work is planned on sealing the seams that have already been filled with any material, you must first remove the old material. For such manipulations, a special cutter or composition for removing silicone is ideal. After completing the preparatory work, wipe the surface with a damp cloth.

Work in places where a fungus can form, for example, a kitchen or a bathroom, requires mandatory treatment of the work area with a fungicidal composition, followed by drying it with a building dryer.

To the edges were smooth and neat, you can use masking tape. It is very important to give the composition to dry well. Typically, manufacturers indicate the time period for complete curing on packaging. As a rule, it is 24 hours. But a lot depends on the thickness of the applied layer, temperature and humidity.

If there is a need to buy a clear sealant for repair, you should examine its composition. Quality products are 90% silicone rubber, the presence of all other fillers and additives should not exceed 10%.

Products that contain “A” on their packaging will give off a sharp smell of vinegar. Works with such products are performed only in a respirator, goggles and gloves.Silicone acid sealants are universal compounds, so you can work with them in almost any place.

If the amount of deposited means exceeds the required amount, additional tools are used. From the concrete or wooden surface, the excess layer is removed with a rubber spatula or knife. All removal work must be carried out promptly and very carefully so as not to spoil the surface. Immediately after applying the excess sealant will remove a wet sponge or cloth. The product is washed off the skin with soapy water.

For how to choose a sealant, see the following video.