Characteristics of bricks according to GOST

Clay brick was and remains the most sought-after material for decoration and construction of buildings. It is universal, with its help you can build structures of any shape, as well as insulate, decorate rooms and perform other work. All these requirements are governed by GOST 530-2007.

What is it like?

The building stone (brick) is a piece product which is made from clay and put on a solution. The standard product has a regulated dimensions of 250x120x65 mm and is a parallelepiped with smooth edges and edges.

All types of building stone are made according to a single standard, regardless of whether it is facing or building material. Such requirements are imposed on clinker bricks, despite the fact that it is made using a different technology,as a result, it has higher strength characteristics, which makes it possible to apply such products in places where large loads on the surface will be affected. The cost of such a product will be much higher than the usual equivalent.

Species

Brick today is presented in several forms.

- Private. An ordinary brick with standard dimensions that does not have voids inside. Its cost is available, it is used for the construction of various structures.

- Full bodied There are a small number of voids, the total volume of which does not exceed 13% of the volume of the product itself.

- Hollow. It has different configurations of voids in the body, which can be through and non-through.

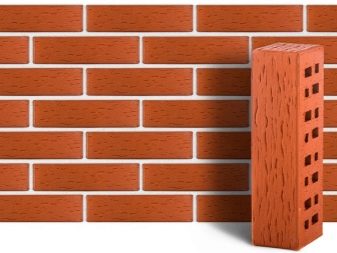

- Facade. It is presented in different forms, it is applied to finishing of facades.

- Clinker. Differs in high durability, does not absorb water. Used as a decorative material for landscape design. The dimensions are the same as for the standard product, but if necessary it can be made in other parameters.

- Facial. Refers to decorative materials, but the characteristics are not inferior to ordinary bricks.Meets all the requirements for strength and other indicators.

- Ceramic stone. A product made of ceramics, which has many voids inside and differs from ordinary bricks by its large size.

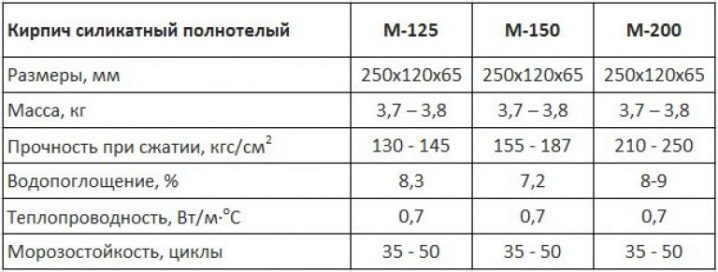

Marking and designation

According to the strength characteristics of the bricks are divided into 7 types. Strength is indicated by the letter "M" and the numerical value that comes after it. For the construction of small outbuildings, fences and low buildings used ordinary bricks M100-M200. If it is required to erect a high-rise structure or use a brick in places where large loads will act, it is recommended to give preference to products of the M300 brand and higher.

The batch number and its mass are indicated on the surface of any ceramic product. Manufacturers can specify other data that does not contradict the standards and provide an opportunity to quickly identify the products of a manufacturer.

Specifications

- The main requirement that is imposed on the face brick is its appearance. Typically, such products have textured, glazed coatings with the application of a certain relief.Ordinary bricks have no decor on their surface. They are produced in natural color, and, if necessary, painted in the desired shade after laying.

- According to GOST 5040-96, a slight deviation of the dimensions and characteristics of ordinary bricks is allowed, among which chips, cracks, abrasions and other defects can be noted. In this case, the same flaws should be excluded from the front brick, which subsequently will not be plastered.

- Facing brick is more expensive, especially if it applies to the stones of the first grade Sha 5, which should not have any flaws on its surface. The presence of brick voids reduces its weight, which makes it possible to reduce the pressure on the foundation during the construction of walls. Also, such bricks are used instead of tiles for finishing already built houses. At the same time, the facade is affected by a minimum load, while the structure itself takes on an attractive appearance. Such surfaces are easy to clean and keep clean.

Advantages and disadvantages

Any clay brick has its strengths and weaknesses, like other materials.

The advantages include:

- high density values;

- resistance to low temperatures;

- practicality of use;

- fire resistance;

- environmental friendliness;

- the ability to carry out various projects regardless of the complexity of the design;

- a wide range of products;

- with experience, the masonry can be made on its own;

- aesthetic qualities.

Minuses:

- fragility;

- rather high cost of certain types of bricks;

- with adverse factors, surface efflorescence may occur;

- masonry requires certain skills.

Transportation and storage

If it is necessary to transport the bricks, they should be packed in special material or placed on pallets, which will protect them from atmospheric and other impacts. Products from the same batch are put on pallets, so that they do not differ in the parameters and color. If necessary, you can store bricks in open areas, taking into account seasonality.

Transportation is carried out by any car or other type of transport in compliance with the requirements. Pallets with bricks are mounted on the body to prevent them from falling and damage.

Before going on sale, all bricks must be checked for compliance with standards.All these activities are carried out at the plant that manufactures them. During testing, samples are randomly selected that are tested and tested for frost resistance, strength, water absorption and other characteristics. All these data are indicated in the passport of the product.

Test methods

In order for an organization to sell its products, it is necessary to pre-test them. This is done in laboratories where the following characteristics are verified.

- Geometry deviations. In this case, the parameters of the products are checked with a ruler. Deviations should not exceed the requirements of standards in accordance with GOST.

- Absorption. Initially, the brick is weighed, and then placed in water for 24 hours, after which it is weighed again. The difference in performance determines the degree of absorption.

- Strength. The sample is placed under the press, where a certain pressure is put on it. As a result of this test, the ability of the product to withstand a particular weight is determined.

- Frost resistance. The sample is placed in a special chamber, where it is exposed to low and high temperatures alternately.All these cycles are calculated, which makes it possible to determine the number of cycles of freezing / thawing of the product during its further operation.

- Density. It is determined using a special device.

- Thermal conductivity. The resistance to heat transfer and the ability to retain heat in the room is checked.

After successful tests, the manufacturer receives a certificate of conformity for the goods.

Selection features

To prevent waste of money and make a bargain, necessary when choosing a brick to pay attention to the following points.

- The appearance of the product. The brick should have a uniform color, which says that it is not over dried.

- Products should not have mechanical damage to the surface. Allowed no more than 2-3 percent of such bricks in the party.

- All goods must be packaged and certified.

- It is worth refusing to purchase products from unverified manufacturers.

As you can see, GOSTs are important not only for manufacturers, but also for buyers. If the latter will have the necessary information about a particular product, this will allow them to avoid purchasing low-quality material.

How to choose a brick, you will learn in the next video.