Clinker brick: features, types and uses

Clinker brick is one of the most reliable and durable materials. Due to its high strength, it greatly exceeds the usual ceramic blocks. Increased technical and mechanical, custom and decorative options make this material optimal for facades.

What it is?

Clinker blocks are a modern variety of ceramic bricks, which are characterized by increased density due to special technology.The name of this material received by its characteristic ability to make quite a ringing sound when lightly struck with a metal object - translated from the German “blade” means “pure bells”.

Due to its aesthetic appeal, unique texture and diverse color palette, the products are used for cladding facades and interior decorating. The raw material for clinker production is special clay with unique physicotechnical properties; it is burned at a temperature exceeding 1000 degrees to maximum sintering. During this treatment, a glassy mass is formed on the surface, which makes the brick so attractive in appearance.

History has it that for the first time clinker blocks began to be produced in the middle of the 18th century in the Netherlands. At that time, Europe was covered by a construction boom, which led to a shortage of building materials, as a result, engineers and technologists of that time were forced to look for new options for the production of blocks and bricks. For the first time the product was used for paving roads, in terms of external and physical features, it looked more like a cobblestone, but it was much easier to lay and much cheaper.All this led to the high popularity of the product during the construction of urban roads.

The beginning of the XIX century was marked by a sharp jump in the growth of the largest European cities. The existing quarries could not cope with the pace of construction and could not fully provide the city with the required amount of materials for the construction of new buildings. This led to the need to search for a new material, which in its operational parameters would be very similar to natural natural stone, but at the same time it could be produced quickly, easily and in any volume. This brought scientists to the idea of using clinker not only for roads, but also for building houses.

During this period, small artels began to emerge, which mastered the release of this material - over time, most of them became the largest corporations that received a world name. Many of them are still considered leaders in the segment of construction materials production. So, let's see what a clinker brick is.

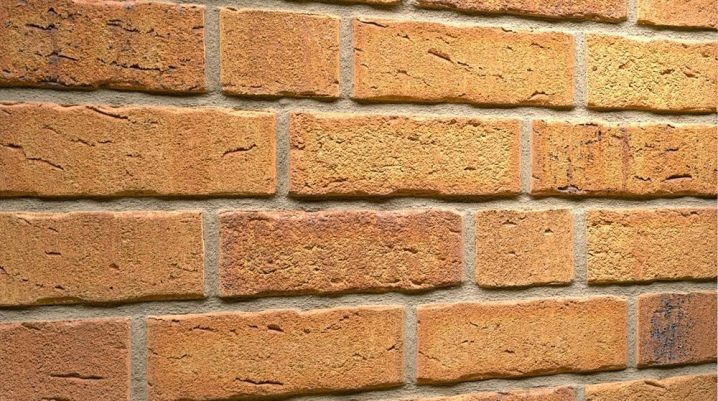

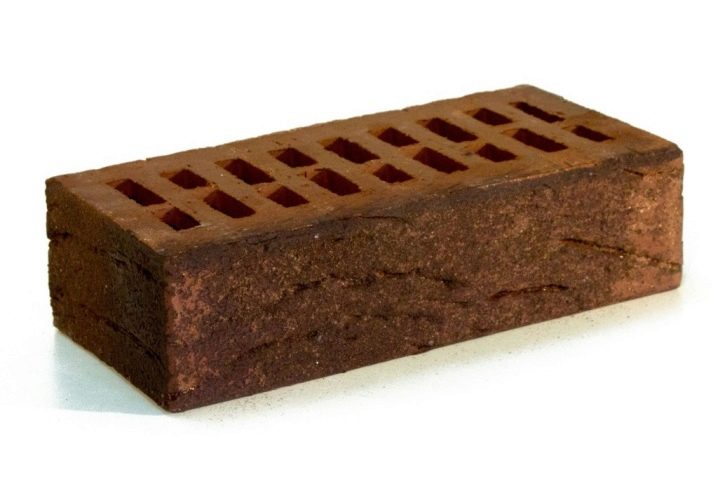

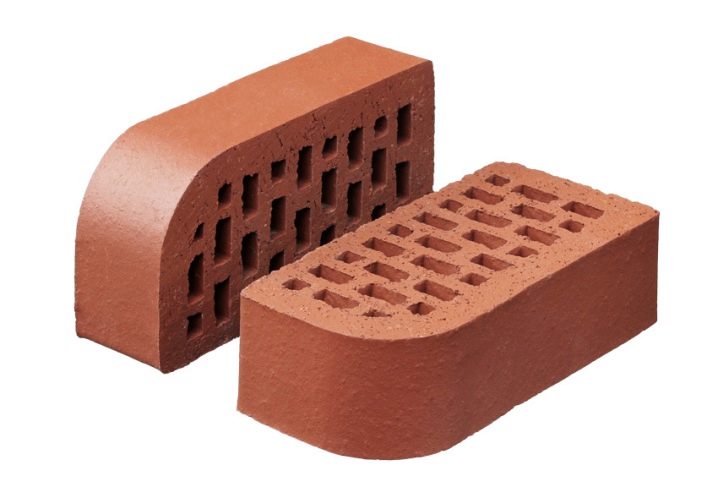

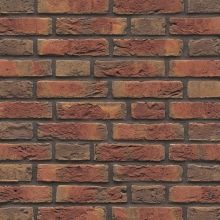

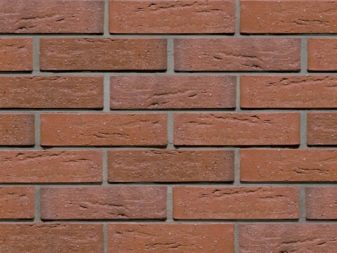

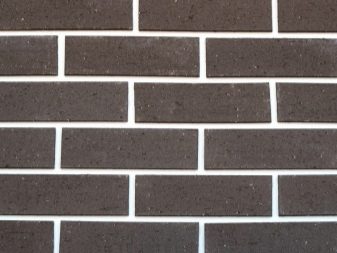

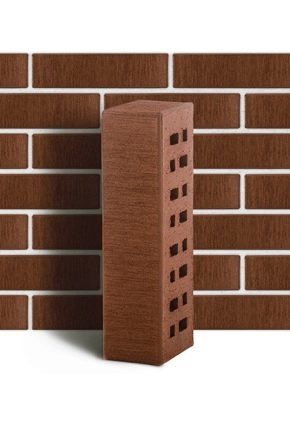

This is a building block, which is characterized by high strength, low water absorption and exceptional decorative effect.A set of such qualities makes it suitable for use in aggressive external environments for interior and exterior decoration. The clinker brick is characterized by a regular shape and resembles a parallelepiped with a rough surface. The color scheme is quite wide - from straw shades to rich chocolate.

Due to the fact that at the manufacturing stage, the material is exposed to temperatures up to 1,400 degrees, the brick acquires an increased density, which is 1 ton per square centimeter. This brick is resistant to fungi, rot, mold and other microorganisms that can destroy the material itself and create a threat to human life and health. Production of clinker bricks complies with current regulations and building standards set in GOST 32311.

Specifications

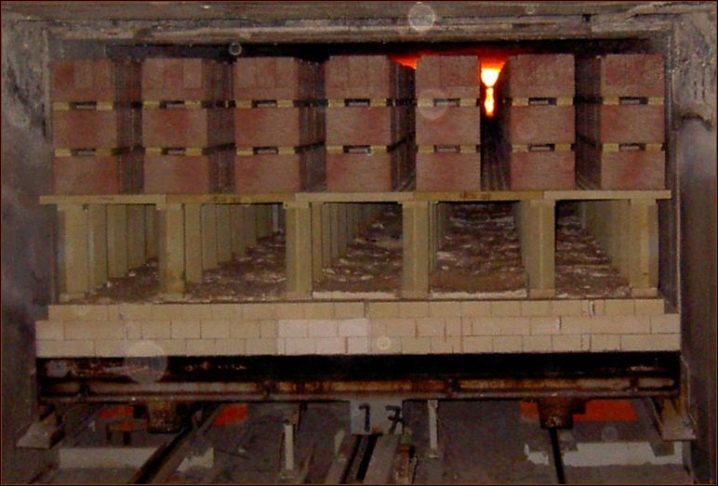

Technical characteristics of clinker brick due to the peculiarities of its production. First you should know that for the manufacture of such products is used only a special type of clay, which is called "skinny". For this purpose, mineral materials of magmatic origin are used.The mixture is fired in furnaces at a temperature of from 1000 to 1400 degrees up to the stage of a glass phase - this is the difference between the clinker block and the usual one, which is fired at 600-800 degrees.

The unique production technology allows us to achieve a high degree of strength, resistance to strong mechanical damage and prolonged abrasion to a degree that exceeds the corresponding parameter of even the highest quality concrete. As a result of exposure to elevated temperatures, the product acquires a special hygroscopicity so that the coefficient of water absorption is only 8%. For comparison, for a regular red ceramic brick, this parameter is in the range of 20-25%.

Let us dwell in more detail on the features of the production cycle for the production of clinker bricks. For the formation of such blocks, clays with an overestimated alumina content are used, whose share is 20-25%. The presence of these components in many ways reduces the viscosity of the raw material, thereby preventing the deformation of the finished product when firing clay. If the production is used raw materials with a low content of oxides, then it is pre-enriched with kaolin.

Iron oxide is also present in the clay; its share reaches d about 8%, due to which the brick acquires a rather characteristic color. At the same time, the amount of these substances should not be higher than the established norms, otherwise a solid layer will appear on the surface of the block, which will interfere with the release of carbon dioxide from the inside, which leads to the formation of irregularities, swellings and deformations.

Raw materials should also contain no more than 8% calcium. If the concentration of this component is too high, then the sintering time will decrease, and this, in turn, will lead to serious deformations of the finished product. In addition, the likelihood of the appearance of pores in internal cavities increases, which increases the rate of water absorption and reduces the lifetime of the brick. The concentration of magnesium oxide in the clay should remain at the level of 3-5%, if the proportion of the substance is higher, then it can shrink the clay and bend the finished blocks.

Clinker products are made by two main methods: extrusion or extrusion. In the first case, all the prepared raw materials are stirred until a homogeneous mass is obtained and then sent straight to a special container, which is called an extruder.Here, the material is subjected to pressure, and through a special molding hole, the clay is squeezed onto a conveyor in the form of a rectangular strip with pronounced geometrical parameters.

This volume strip, moving along the belt, is molded into separate blocks - this is how the so-called raw bricks are created, they are sent for drying, where the humidity drops to 2-3%, and then they are burned. The main advantage of this technology is to obtain high quality bricks with pronounced geometric lines and dimensions. At the same time, such a production cycle requires high energy costs, which generally increases the cost of production.

Pressing allows you to get cheaper products, because it significantly reduces energy costs. The essence of the method is that the clay mass is dried, crushed to a powder, poured into special forms and subjected to high pressure and press. The finished blocks are then delivered to special chambers for finishing drying, where they are kept for about two days when heated to 85 degrees.Only after that the bricks are sent to the kiln for firing.

As a result of this technology, the clay is almost completely sintered, as a result, a fairly strong clinker block with the required decorative properties is formed. Features of technology make the product more durable. The main physico-technical properties of clinker brick are:

- mechanical strength - 25 MPa;

- water absorption rate - less than 6%;

- material density - varies from 1600 to 2100 kg / sq. m;

- frost resistance - F 300;

- thermal conductivity - about 1.17 W / ms;

- compressive strength - from 250 to 350 kg / sq. cm;

- thermal conductivity - 1.15 V / Mk;

- Duration of operation - up to 150 years.

Of course, for the average consumer these parameters will say little, but for the professional they are very important.

Advantages and disadvantages

Increased resistance to prolonged frosts and reduced water absorption - all this causes the main advantage of the clinker brick, which consists in the duration of use. Let us dwell on these and other advantages of the material in a bit more detail.

Strength

Unlike traditional ceramics, the clinker block is distinguished by a much greater indicator of flexural strength, as well as compression and abrasion.Brand strength of the material corresponds to the M300, so that the products for many decades retain their original appearance.

Low water absorption

Once inside any building material, moisture has the most adverse effect on it, destroying the structure from the inside. Obviously, the less water gets inside the structure, the more durable and reliable this material will be. Among all types of bricks, it is clinker that is distinguished by minimal water absorption, which averages 3-6%, so even prolonged contact with the aqueous medium will not lead to destruction and deformation of the blocks.

Frost resistance

Clinker can withstand up to 200 cycles of freezing and defrosting, the material does not collapse even at extremely low temperatures, so it can be used in the most northern regions of our country.

Wear resistance

The clinker blocks do not lose their physical and technical properties under the influence of salts, alkalis, and acids. They remain unchanged also under UV radiation.

Color palette

Clinker bricks come in a wide range of colors that can satisfy even the most demanding homeowners.In the course of production, the raw material passes through the stages of gunning and rustication, due to which it receives exclusive invoices.

Environmental friendliness

Clinker products are made only from natural materials, even unique shades are achieved by mixing different types of clay. Therefore, the finished products meet all the requirements of environmental safety, do not emit toxic substances and do not contain radiation.

Let's see what other problems can solve the use of clinker brick in construction. Surely, many people noticed that the facades of even new buildings are often covered with an ugly white bloom (efflorescence). This phenomenon is due to the fact that salts and sulphates present in the clay begin to emerge over time. This kind of behavior is completely unusual for a clinker, although the source material, like any other, contains all these components. However, during the processing of them simply does not remain: sulfates and salts under the influence of temperatures of 1,400 degrees fully sintered and begin to participate in the melt.

Another problem facing blocks are "shots", they are associated with the presence of calcium and magnesium salts in the structure of the clay raw materials.These substances, much earlier than all the other components of the raw materials, go into a melted state and begin to work as solvents for all other components. There is only one small "but" - perhaps this is only when heated more than 1000 degrees, and this is the conditions in which the clinker brick is burned.

In the production of conventional products, a lower temperature regime is used; therefore, the oxides remain completely in the blocks; as they come into contact with water, they begin to increase in volumes, leading to the appearance of surface defects. In the people they are also called dutikami or shots. Everything would be fine if these phenomena only worsen the appearance, but they lead to the formation of cracks - and this significantly reduces the lifetime of the structure as a whole.

Such exceptional qualities led to a rather high cost of clinker bricks, which can be called the main drawback of blocks. Not every Russian can acquire clinker. In addition, clinker requires the use of special bonding compositions, traditional cement and lime mixtures are unsuitable here. Well, one more minus isthat in different batches the shade may differ, so when buying building materials try to get everything from one release, for this you need to know exactly in advance how many bricks you need.

Kinds

The variants of clinker material presented nowadays explain the peculiarities of using all types of such products.

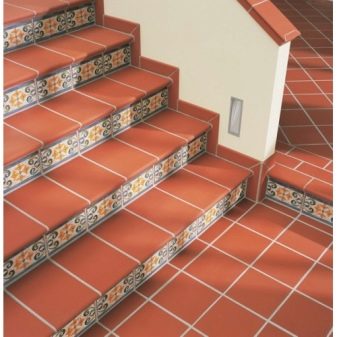

- Facade tiles - it is a separate subspecies of facing small-piece material, which is used as a facing material for various interior works in any type of premises.

- Technical clinker found wide use for decoration of garden paths, as well as sidewalks, grounds both on the street and inside the premises. A separate type of such material is paving clinker - it has the same direction of use, but has a higher cost.

- Waterproof clinker - this product is universally purchased for the construction of hydraulic structures, which are operated in conditions of high humidity.

Specialized clinker allows you to produce interior and facade decoration of surfaces with a variety of forms.Products, as a rule, belong to the small-piece category, therefore they can form various angular elements of decorative surfaces.

It should be noted that the manufacture of all types of clinker (besides the facade one) is not legally standardized, therefore, it is carried out in full compliance with the technical conditions of a particular manufacturer. Clinker blocks are produced in a variety of formats - from classic to non-traditional, this feature allows you to implement any design ideas.

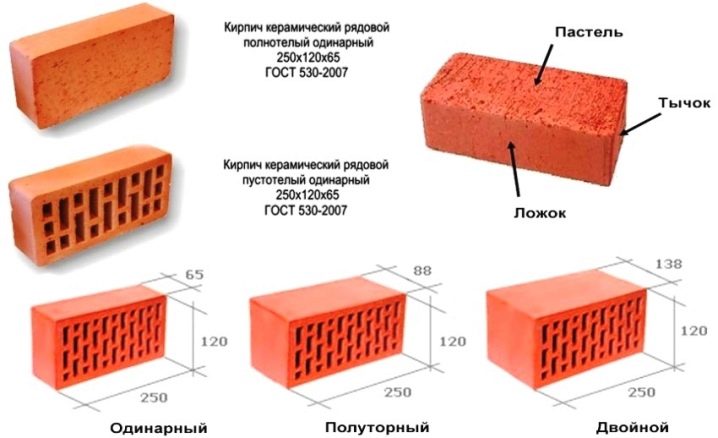

Standard sizes are:

- base brick - 24x11.5x7.1cm;

- single - 25x12x6.5 cm;

- Euro - 25x8.5x6.5 cm;

- half - 25x6.2x6.5 cm

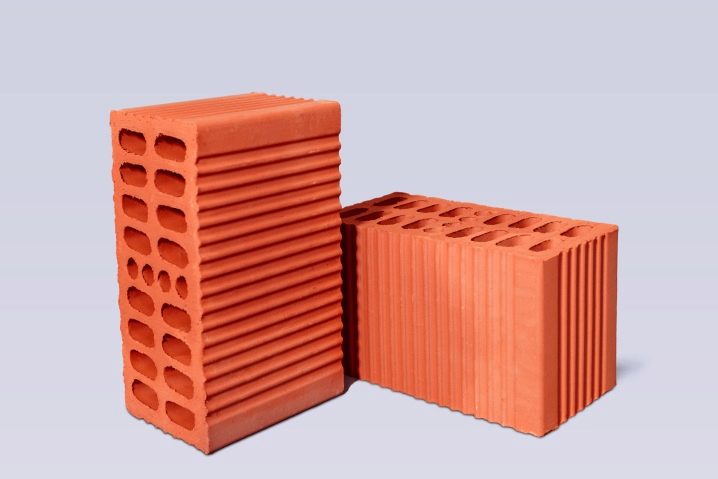

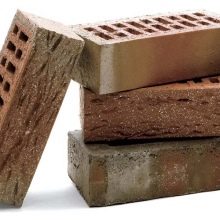

For non-standard forms, deviations from the specified indicators are allowed. The weight of bricks ranges from 1.6 to 3.3 kg. The clinker blocks can be hollow and corpulent, and, depending on the production technology, there are bricks made by hand molding and conveyor bricks.

Design

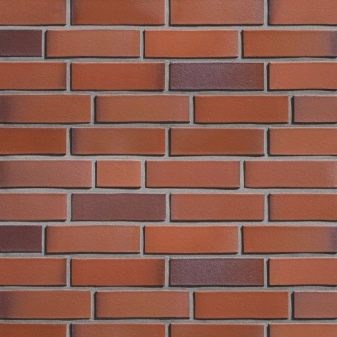

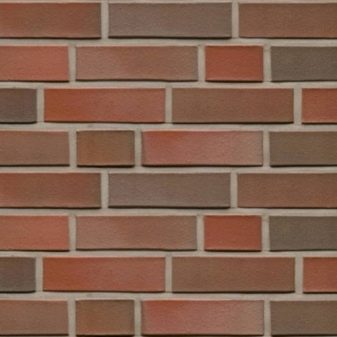

When choosing facial materials, the color range and texture of bricks is quite important. The building, especially if it is a residential building, must not only be strong and durable, but also attractive.That is why the owners of cottages and private houses quite often acquire clinker blocks, which allow you to choose the necessary colors and shades so that the house becomes truly exclusive.

It is possible to list all the tones in which these products are produced for a very long time, the color palette has several dozen colors, including white, straw, yellow, brown, gray, chocolate, red, brown, terracotta, purple, blue, black and many others. Bricks can be combined with each other, creating an interesting mix of different colors and shades, and some manufacturers even produce bricks with smooth transitions, for example, from red to violet.

Textures can also be the most diverse - smooth, punctured, grooved, with dressing, “under the stone” and so on. Quite popular are the “antique” bricks - that is, artificially aged. It is noteworthy that to achieve such effects, the surface of the block is not covered with anything. All shades are obtained by combining several types of clays and the effects of different temperature regimes during firing.

Scope of application

Clinker bricks are commonly used for cladding facades of buildings and structures of various purposes, from large retail and office complexes to small private houses. In recent years, fences and fences in the private sector have been erected everywhere from these units, in addition, the material is suitable for arranging plinths and basements, it is also indispensable for interior decoration. Let us dwell on the most popular options for the use of clinker.

Facade

Modern construction technologies are increasingly involving the construction of three-layer walls, which consist of the main brick, insulation layer and clinker cladding. This design fully complies with all the requirements for the construction of residential buildings, while this building looks very impressive and stylish. Such a facade is characterized by resistance to various mechanical damage and adverse natural influences, and low water absorption protects the walls from destruction, reproduction of the fungus and dangerous mold health. It is noteworthy that the lining of this material can be easily disassembled, so if necessary, you can easily and easily replace the insulation coating.

Walls

Clinker blocks are often recommended to be used for the construction of walls, so the structure becomes more solid, strong and very durable. In this case, the overlap consists of two layers - the laying of the usual ceramic or silicate brick and masonry facade clinker. In this case, both walls are fixed to each other using stainless steel or galvanized steel anchors.

Other uses

In addition to cladding facades and wall structures, the clinker product can be used to implement a wide variety of architectural and design ideas. The clinker is used to build street barbecues, barbecues, as well as stoves, columns and fences. Especially popular was the material in the arrangement of pavements, paths and curbs. Due to the rich color scheme, it fits perfectly into the landscape design and creates quite stylish accents in the arrangement of the surrounding areas, city parks and squares.

Piling

Work on the installation of clinker blocks should be carried out in compliance with the technological requirements. The first layer is usually laid out without the use of a special solution.This is necessary in order to obtain an even and clear marking of vertical seams. As a rule, their width is about 1 cm. After all the markings are fully applied to the facade, the first horizontal seam, which is about 1.5-2.5 cm wide, will become noticeable. The brick is laid out in whole layers, taking into account their average heights.

When forming ventilation holes in the wall, it is necessary to create conditions for the free movement of air in the lower part of such a laying. To do this, every four rows must be left one vertical seam unfilled. When creating each subsequent layer of mortar, you need to look at it so that it does not fill the free air space, for this purpose it is pressed with force with a trowel to the blocks. All subsequent layers must be laid out to the middle of each layer. When the masonry is finished, it is necessary to scrape the mortar out of the seams approximately 1.5-2 cm in depth; for this purpose, a trowel is usually used.

Manufacturers

Clinker bricks are supplied to our country from China, Germany, Holland, Poland and Spain, although in recent times some Russian manufacturers have mastered the production of such blocks. As a rule, exclusive products can be purchased only under the order, but budget options are available at any hardware store in every city in Russia.

- CRH Company - This is one of the world leaders in the segment of brick production. The brand has been operating in the market for over 40 years and, under its wing, unites a large number of manufacturing enterprises located in various countries.

- ADW Klinker - this concern has been selling its products on the territory of our country for about 10 years and all this time has been tirelessly expanding its product portfolio. A distinctive feature of the products of this brand is a bold color gamut, which is achieved due to the characteristics of the raw materials used. The fact is that in the production only white clay and mineral multicomponent additives are used, thanks to which you can get almost any desired shade.

- ADW Klinker - this brand in recent years is rapidly gaining popularity due to its truly German quality. Products from this manufacturer can be used in areas with the most severe winters, while maintaining all operational features in full.

- Daas Baksteen - This is a Dutch company with more than a century of history.The brick of this nonsense is characterized by bright colors and beautiful colors. Products are made out as paint stains or brush strokes.

- Rauf Company - this is perhaps the only well-known domestic manufacturer of clinker bricks. Unfortunately, our production of this type of building materials is not yet as developed as in Europe, but Russian manufacturers have something to offer the consumer. Domestic bricks of this brand meet all European standards, however, the price for them is much lower and more affordable, since customs costs, transportation costs and other considerable cost items are not included in the cost price.

- In the opinion of our compatriots, the Russian company LSR has also recommended itself well.

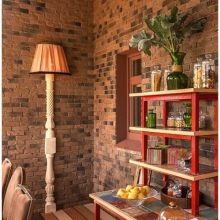

Beautiful examples in the interior

Some people think that brick is not the place in the interior decor, believing that this is a rather “uncomfortable” material - as if we are on the street, not at home. At the same time, many will argue that this is the main advantage of clinker. Since the contact of cold stone, warm cozy carpet with soft furniture and flowing curtains creates a real high style.

What is clinker brick, you will learn from the video below.