Selection and installation of caps on brick pillars

Columns of stone or brick perform the support-separation function between the sections of the fence. At the end of the construction work, caps are mounted on them, which give the structure an aesthetically complete look and protect it from the harmful effects of the external environment. A variety of materials from which the overhead structures are made, allow you to pick them up to any fence, given the style and structure of the structure.

Functions

Caps on supports for fencing carry protective and decorative functions. If they are not installed, then the following processes will occur under the action of the environment with brickwork:

- the impact of moisture on the brick leads to its destruction, it begins to crumble;

- the solution is gradually washed out;

- a direct hit of precipitation on the upper part of the unprotected masonry can change color and deform the structure;

- hollow pillars are particularly affected, they become clogged with mud and water;

- in winter, the water, freezing, expands and causes cracking of the building material or its complete destruction.

Poles that are not protected by caps will not last long and will need constant repair.

Pads have all the necessary technical characteristics and solve the following tasks:

- they are hermetically put on the poles, protecting them from external influence;

- the strength of the coating material makes the laying durable, prolonging the terms of its operation;

- inconspicuous and reliable fastenings do not spoil the appearance of caps;

- the slope and grooves of the construction protect brick columns from precipitation;

- material for linings is selected to be resistant to corrosion and physical stress;

- the fence gets flawless appearance;

- a large selection of material and configurations styling lining under the fence of any type;

- caps are decorative load, they can be decorated at the request of the owner or used as a place for additional lighting.

Kinds

Fence caps are diverse, they can be classified according to the methods of manufacture, configuration, and the material from which they are made.

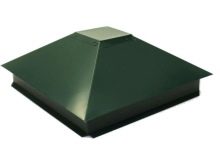

The form is selected depending on the style of the fence and the preferences of the owner. It can be dome-shaped, with four slopes, conical, in the form of a pyramid or an eastern pagoda.

Caps produce different configurations, but conical and triangular shapes are considered more rational, which allow precipitation to flow down without stopping.

Sometimes they are decorated with a spire, a lamp, sculptural figures. All these elements must be made of durable materials that can withstand weathering.

Consisting design consists of upper and lower parts. Fastening is the bottom of the cap (skirt), rather densely implanted on the pole and becomes almost invisible under the upper part. The cap itself is sealed, has an attractive appearance, its design from the bottom ends with slopes and grooves to remove moisture.

If the pad is made with lighting elements, a platform for a decorative street lamp is made at its highest point.The cap can be decorated with any exterior decoration that meets the designer’s or owner’s plan. The cover of the pillars looks good and immaculately and without the presence of decor.

Technically, caps are made in different ways - by casting, stamping, they can be made by welding, bending in different ways or creating forged products.

More varied lining the composition of the material from which they are made.

Metallic

Some owners make their own caps of tin. The caps produced with the participation of forging look spectacular. The industry produces nozzles made of stainless steel, copper, brass, galvanized. In order to avoid corrosion, polymeric coatings are applied on caps, it can be plastisol or polyester. Copper and brass products can last more than a century without replacement.

Metal plates make figured, they become a kind of decoration of the fence.

They should be periodically reviewed and treated with special formulations, avoiding smudges and corrosion, and care is the same as professional sheet work.

Sheet metal is often lightweight, such products should not be installed in areas with strong winds.It is necessary to take into account the sounds that metal makes from being hit by raindrops or hail and not placed near the windows of a residential building.

Concrete

They weigh up to 20 kg, they will not be blown away even by strong wind, but its constant impact on concrete will have a negative effect over time, this should be taken into account when installing such products in windy places. Concrete pads are molded of any shape and are well sealed with mortar. They are installed on brick pillars, if the fence is made of stone, concrete or brick. Similar caps for other types of fences are not suitable.

Concrete pads perform in color, which repeats the shade of a brick pillar or comes with it in contrast. This product looks reliable, presentable, and if it is of high quality, it is. Substandard concrete caps, in the opinion of the owners, after a year acquire the form of a shapeless lump.

Stone

Products come from natural and artificial stone. Natural stone looks great, has a special strength and durability, but it weighs a lot and is expensive to owner. The product of artificial production is much cheaper, it cannot compete with natural stone in quality, but it will provide a solid, majestic look to the structure.

Ceramic

This is a beautiful mosaic type of linings, it looks elegant and expensive. It is, indeed, quite a lot. Handle with such material should be careful because of its fragile structure.

Polymer-sand (composite)

The latest development, which has already been appreciated and chosen by consumers for its durability, affordability and impeccable appearance. Make of sand, polymers and various modifiers. They have a wide range of colors, imitate natural stone, tiles, are transparent to establish internal lighting.

With a composite material, it is possible not only to cover the pillars, but also the brick fence itself.

Plastic (PVC)

Cheap lightweight material, not durable. Used for temporary protection of pillars.

Wood

Such caps are easy to make with your own hands, they are well in tune with the landscape of the garden. Can have various forms, up to sculptural. They meet the special styles and ideas of the designer.

This is the most short-lived material that requires special impregnation and constant care.

Bituminous

Created from soft tiles. For the formation of caps suitable trimming of building material after roofing.The hydro insulator is liquid rubber.

Fiberglass

Thanks to innovative production, beautiful, light and durable caps have appeared that can withstand temperature fluctuations from minus forty to plus ninety degrees. The density of the product ensures the content of polycarbonate with acrylic and quartz glass. They can not be scratched and easy to mount.

Illuminated lining has a fantastically beautiful view.

How to choose?

When choosing a product, you need to have a minimal idea about it. The pillar cap consists of two parts: the bottom one is the mount that holds the covering element on the surface of the brickwork, the top one protects the structure from the aggressive manifestations of the external environment and at the same time decorates it.

The main criteria for selection are the size (it should fit perfectly) and the compatibility of the material, style, volume with the support post and the fence itself.

Compatibility of caps depends on many factors relating to a wide variety of areas. But first of all it is necessary to combine them with those elements for which they are purchased.

- Concrete pavement, because of the large weight, suitable only for pillars and fences made of brick, artificial and natural stone, as well as concrete fences. They can not be combined with metal and wooden supports.

- Metal caps, thanks to the hollow form, used in cases where it is necessary to hold the lighting. They are combined with metal spans. But by and large metal is suitable for masonry and any other type of pillars.

- Stone lining combined with a brick base, but more harmoniously they will look with stone, for example, a white marble column completes its image with an ideal coating of the same material.

- Wooden caps blend well with the brick base, but wood must also be present in the canvas of the fence itself.

- The same applies to forged products, brick pillars, having such caps, should repeat the elements of forging, if not in the fence itself, then at least in the decoration of the wicket or gate.

When buying caps, in addition to size and compatibility, you should pay attention to other criteria:

- first of all, check the accompanying documents, certificate of quality, warranty services of the goods;

- you must make sure that the size of the coating fits the support, otherwise you will have to look for another type of caps or order them individually from the manufacturer in size;

- the symmetry of the corners must be checked, the elements must not be skewed;

- the lower part of the cap is viewed for tightness, its defects will further lead to the destruction of the pillar;

- eaves overhangs should be sufficient to protect the support from precipitation;

- products must be carefully considered to eliminate scratches, chips, dents and other defects;

- packaging impairment is always suspicious;

- Before buying, check the complete equipment of the goods.

Color and design of caps are selected according to the style of the fence or the taste of the owner.

How to make?

Many craftsmen prefer to make caps on their own. Materials for this use a variety.

Of metal

Most often for homemade galvanized metal is chosen. They work with the help of a sheet bending machine, the form is aligned with corners, the fasteners are produced by rivets. Below to the pattern fix tin strip to create a skirt. The product is painted in color, in harmony with the fence.

If you do not have the skills of the tinsmith, it is better to do the preparation on paper. Who is familiar with the blacksmithing, can decorate the cap with forged elements.

From soft roof

When the roofing work is completed, you should not throw out the remains of soft tiles. It can be used to create overlays on support columns. In this work, besides the tiles, you will need corners, with their help they form a cap that resembles the roof of a building. This element of the fence supports styling the house.

Out of tile for outdoor work

You can use facing or paving material. It is good if the tile coincides with other building elements of a house or plot, for example, it has paved garden paths, or faced a barbecue area. She may have a match in color with the roof, fence or wicket.

Such coatings are flat, they are easily fixed with cement or tile adhesive.

Out of concrete

Forms of the required configuration are prepared from tin or profile sheets, with the help of which the products will be cast. For the manufacture of mortar, cement is mixed with sand and plasticizers, crushed fiber is added for strength.All dry ingredients are thoroughly mixed, then water is introduced and mixed. The resulting mixture is poured into prepared forms, cover with cellophane and leave to dry completely.

From wood

The desired shape is made of wood using a saw and jigsaw. A well-polished product is impregnated with antifungal agents, coated with paint or varnish.

The masters with the help of woodcarving achieve fabulous results - their caps acquire amazing geometric shapes or sculptural images.

How to install?

Ogolovniki made from different materials, so the installation for them will not be the same.

Installation of concrete and ceramic products:

- the surface of the pillar is thoroughly cleaned;

- for reliable adhesion, it should be treated with a primer, then with a waterproofing compound;

- apply glue or concrete mortar on the surface;

- install a cap;

- check the installation in vertical and horizontal position;

- fix the seam with waterproofing compound;

- let dry for several days.

Installation of metal caps:

- put markings on the pole and drill holes for fasteners;

- put the lower part of the cap on the glued surface of the support and fix it with a screwdriver (if the construction is separate);

- on the skirt install the upper part of the head.

Caps are an important element of the bearing pillars, without them the structure seems to be unfinished, does not have an attractive appearance and is subject to gradual destruction.

How to make caps on brick pillars with their own hands, see the following video.