Sizes of facing bricks

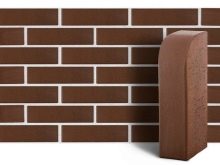

The main materials used in construction for the walls of buildings, often not aesthetic and ugly. To improve the appearance of such structures often carry out finishing work, which is used for facing brick. It can be both standard and non-standard dimensions (but nevertheless approved by GOST). What types of facing bricks exist today, we will tell in this article.

Destination and species

Facing buildings with bricks not only improves their appearance, but also creates additional protection from the adverse effects of the external environment, and also increases the strength of the erected walls.

The classification of bricks is carried out according to several basic features:

- on production technology - corpulent and hollow;

- by the method of manufacture - with the help of special equipment or manually;

- by type of surface - smooth, rough (dull);

- on finishing;

- by color - red, white, yellow, etc .;

- on production material - silicate, hyper pressed (concrete), clinker, ceramic;

- according to the quenching method - ceramic (by kiln firing), unburned.

Hollow bricks, in addition to light weight, as compared with full-bodied, also retain heat better (by an average of 10-15%).

Ceramic bricks produced by high-temperature firing prepared and formed mixture consisting of low-melting red clay with various additives correcting thermoplasticity. These additional elements include quartz sand, sawdust, ash, dust from coal, etc.

The main difference between conventional and facing bricks is the more accurate preparation of all the ingredients before the formation of the product itself. This helps to reduce the likelihood of cracks and the appearance of unaccounted elements that can mutilate the appearance of the product.

The finished product has a very high moisture resistance, durability and ability to retain heat. Ceramic facing bricks are produced in a wide variety of colors and textures, which is achieved by adding mineral dyes such as chromium oxide, ground iron and manganese ore and other components to the brick mixture.

The clinker brick in several parameters is similar to ceramic, but differs in the composition of raw materials and firing modes. To create clinker take medium and refractory clay, therefore, its heat treatment requires higher temperatures.

The logical outcome of this is that clinker brick is superior to ceramic in terms of moisture resistance and durability. But he is inferior to him in the conservation of heat. This minus is leveled by the fact that clinker has the ability to effectively resist the ravages of frost.

In color and texture this type of facing bricks is on a par with ceramic.

Hyper pressed or concrete brick is made from a mixture of cement, granite chips and water. This type of lining is not subjected to firing, bricks are simply formed from the mixture, and the process of solidification proceeds naturally.

In the matter of strength, hyper-pressed bricks do not “shrink” before clinkers, they are very resistant to various external influences. Excellent appearance is provided with a rich color range of finished products.

Silicate facing bricks are made from a mixture of silicate sand and slaked lime. This product also does not undergo heat treatment by firing. Accelerate the process of solidification of the brick mass using an autoclave - installation, providing high pressure and temperature.

At the moment, the popularity of silicate bricks has fallen dramatically due to a poor range of colors. As for the technical indicators, they are at the proper level. Silicate bricks absorb moisture better, but they are more resistant to the processes of regular wetting, freezing and thawing.

The various texture of the surface of the facing bricks is made mainly by applying sketches on the not yet hardened mass before firing in the kiln

In addition to this method, the following surface decoration methods are also used.

- Shotcrete Mineral chips are applied on the edges of the bricks.

- Engobing The surface of the product is covered with a special composition, which under the influence of elevated temperature turns into a glossy film.

- Glazing. In many ways, it is similar to the method of engobing, the only difference is in the thickness and durability of the resulting film, since here these figures are greater.

Product dimensions

Bricks for veneering produce different dimensions.

Brick sizing table for veneering

Type of facing brick | Dimensions, mm | Weight, kg | |

ceramic | hollow | 250 x 120 x 65 | 2,3; 2,6 – 2,7 |

corpulent | 250 x 120 x 65 | 3,6 – 3,7 | |

euro (empty) | 250 x 85 x 65 | 2,1 – 2,2 | |

ceramic thickened | hollow | 250 x 120 x 88 | 3,2; 3,6 – 3,7 |

euro (empty) | 250 x 85 x 88 | 3,0 – 3,1 | |

clinker | corpulent | 250 x 120 x 65 | 4,2 |

hollow | 250 x 90 x 65 | 2,2 | |

hollow | 250 x 60 x 65 | 1,7 | |

clinker long | hollow | 528 x 108 x 37 | 3,75 |

unbaked smooth concrete | corpulent | 250 x 120 x 65 | 4,2 |

corpulent | 250 x 60 x 65 | 2,0 | |

corpulent | 250 x 90 x 65 | 4,0 | |

smooth smooth thickened unburned | corpulent | 250 x 120 x 88 | 6,0 |

handmade ceramic | corpulent | 188 x 88 x 63 | 1,9 |

- Standard. The standard dimensions of bricks for facing are 250x120x65 mm. Differences for manufacturing products are found only in thickness. This does not apply to handmade products.

- Single. The thickness of this type of brick is 65 mm.

- One and a half. The thickness index for this type is 88 mm, and for the double - 138 mm.

- Ornamental. The reference dimensions of a decorative brick can be of such values - 250x120x65 mm, 250x90x65 mm and 250x60x65 mm.

- Euro. European manufacturers have slightly different standards for the size of bricks for veneering: for the ceramic product - 250x85x65 mm, for the thickened type - 250x85x88 mm.

Product parameters depending on color

The most widespread shades of facing bricks - red, yellow, white.

The composition of raw materials for red brick is iron, it is made by firing at a temperature of about 1000 degrees. As a result of this, building material receives high strength, durability and reliability in use. It is used for laying the foundation, walls, stoves and fireplaces.

Sand and lime are the main components of raw materials for the production of white building material. Aesthetically attractive, frost and moisture resistant, durable material is not affected by temperature shocks. They build houses, pavilions, fences, etc.

Yellow brick is made from clay with the addition of cement and / or lime oxide. The main advantages are good thermal insulation properties and smallthe cost.

How to choose a facing brick, see the video below.