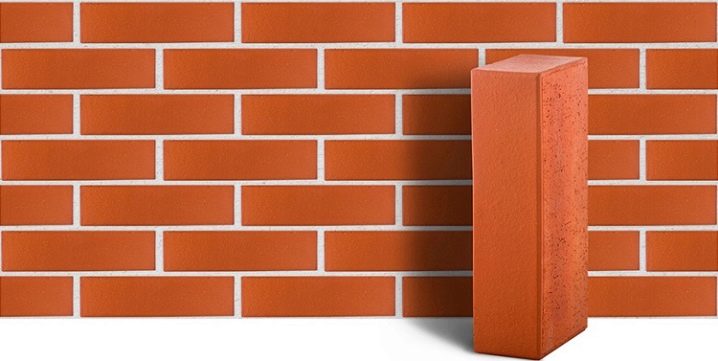

Solid ceramic brick - key features

Among the most demanded masonry materials is red single, full-bodied ceramic brick with a size of 250 x 120 x 65. It is made from clay with the addition of other components, which ensures high material performance. Among them are the high density, frost resistance, thermal conductivity and so on.

Types and classifications

Due to the fact that this product has certain standard dimensions and weight, this makes it possible at the preparatory stage to calculate the necessary amount of bricks for the construction of an object.Known weight helps to organize the issue of transportation of material, to make the choice of the car, depending on its carrying capacity. The ordinary front brick has the standard sizes, usually make a laying of walls of it. Can build partitions and other structures.

It is classified by type.

- Standard.

- Facing.

- Refractory.

Options

The one-and-a-half brick M 125 has various weight which depends on the sizes of the product itself. All these characteristics are determined by GOST 530-2007, and therefore, such material is produced according to the size scale.

- Single. Used for the construction of load-bearing walls or masonry structures (250x120x65).

- One and a half This thickened version of the M100 has a high thermal conductivity and weighs a lot, and therefore it is often made with voids inside to reduce mass. Its size is 250x120x8.8. It happens M125.

- Double. Volumetric brick M200 has improved characteristics and has dimensions of 250x120x13.8. There is an M250.

Since bricks are usually produced in the factory according to certain standards, it is necessary to adhere to the specified values when working. Of course, it is not always possible to produce the same bricks, and therefore they may differ slightly in weight and size.

Depending on the presence of voids in the body of a brick, its cost also differs. For example, a hollow material costs less than full-bodied, since less raw material is required for manufacturing. Hollow samples adhere well to each other in the masonry, cement gets into the voids and securely holds the blocks. The density of the corpulent product is higher.

Weight

Brick ordinary brand has a different weight, which is determined depending on its type. This also regulates GOST. Stones M 200 and M 250 and other types can weigh from 3.5 to 4.3 kg. Each manufacturer should indicate along with the dimensions of its products and its weight, as well as other parameters, which simplifies the choice for the buyer.

Brick density

There are certain reasons that affect the density of a product regardless of its grade. There are several of them.

- Humidity. The main volume of water brick gains only when laying the sample. In the future, this parameter may vary depending on the conditions, as well as the place of use of the material. If a stone cannot hold moisture in itself, it means that it passes air, and therefore a product that absorbs moisture is usually used for arranging cellars, basements and sewers.

- Cracks. The natural properties of the raw materials are cracking when drying, but with the use of polymer compositions today it is possible to achieve an improvement in the density of bricks.

- A variety of clay. From the place of occurrence of raw materials with the same volume, it may have a different weight, which is reflected in the density.

- Red bricks can vary in weight and size., it is a good building material from which it is possible not only to erect buildings, but also to use them for a fireplace or for another purpose. Weight and dimensions of the product are selected in accordance with the place of use. Standard production and the parameters of this material make it possible to initially determine the load on the foundation that it will provide, simplify the method of transporting it to the object.

Applications and Benefits

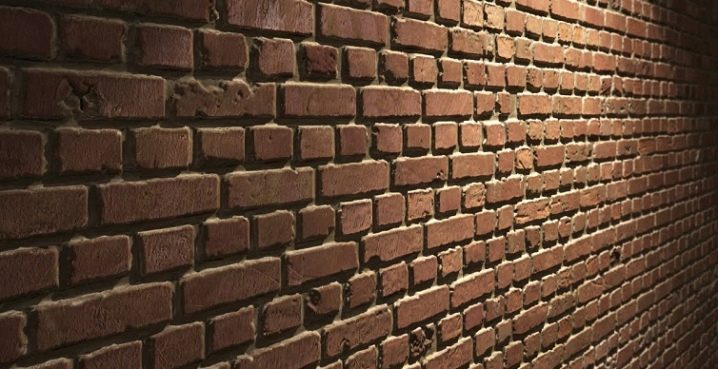

Today, different manufacturers make a large range of ceramic bricks, which can be used for various purposes:

- in the construction of partitions;

- for facing;

- laying of the bases and other.

If we talk about the advantages of this material, then it should be noted that ceramic brick is used more often than other types of building stones.

It has many advantages.

- It is durable and durable.

- Environmentally friendly, cold-resistant, refractory material.

This product does not absorb moisture and can provide good sound insulation, it is harmless to humans and the environment, and also is inexpensive.

Frost resistance

This indicator is important when choosing a material and determines the number of times that a brick is able to withstand a defrost / freeze. Frost resistance is indicated by the letter F, and the class is assigned after testing in laboratory conditions.

In accordance with DSTU B V. 2.7-61-97, the stone that will be used for cladding should have a grade not lower than F 25, and therefore it is worth paying attention to this factor when choosing. Of course, it is also important that the frost resistance rate be slightly higher, but this will affect the cost of the product.

Thermal conductivity

This parameter speaks about the efficiency of heat conservation brick in the room. Thermal conductivity is provided by the structure of the product and the presence of voids in the body. Such indicators are important to take into account when erecting load-bearing external walls in order to determine the need for additionalinsulation. The presence of voids in the body of a brick makes it possible to reduce heat loss and reduce the layer of additional insulation.

Density

This is the main characteristic that is taken into account when choosing a brick and affects its weight and strength. Brick without voids is usually used for the construction of load-bearing walls, and products with voids are used for the construction of partitions and other works.

Typically, the density is taken into account by construction companies that build large structures. This indicator is taken into account when transporting products, as the weight of a brick also depends on the density.

Minuses

Despite all the positive qualities of ceramic bricks, it also has certain disadvantages that must be considered when purchasing. The main disadvantage is that this product cannot be used for finishing or facing the foundations, as it does not have a beautiful appearance, therefore when using such a material, it will be necessary to additionally plaster the surfaces or treat them with other decorative compositions.

Despite such shortcomings, ceramic bricks are widespread and popular, as they can withstand quite large loads.It will not lose its characteristics and parameters throughout the entire period of use, and if necessary it can easily be dismantled and transported to another place for the construction of other objects.

As you can see, this material has certain advantages and disadvantages that must be taken into account when choosing. It is advisable to work with him in the presence of experience in laying, as work may not justify hopes with the wrong approach. It is very important for the construction of various structures to seek the help of specialists who not only help lay out the walls, but also make all the necessary calculations so that the structure can stand for a long time.

On how to choose the right brick for construction, see the following video.