Solid brick: types, sizes and applications

Brick is rightly recognized as one of the most common and unpretentious building materials. He has many positive qualities for which consumers choose him.

What it is?

A full-brick is an environmentally friendly building material made of clay (clay). There are no voids in its structure. Very often, corpulent brick is turned for the erection of both internal and external walls. This material is considered universal. He is not afraid of negative external factors, such as fire, water and low temperatures.

Main characteristics

Before you go shopping for a full-bodied product, should be familiar with its main characteristics.

- Such a material is characterized by the fact that it has a solid body (and therefore, good strength).

- Usually in the mass of solid brick reaches 3-4 kg.

- As for the volumetric weight, it can be 1500-1900 kg / m cube.

- The number of voids in this building material does not exceed the level of 13%, which ensures its high thermal conductivity.

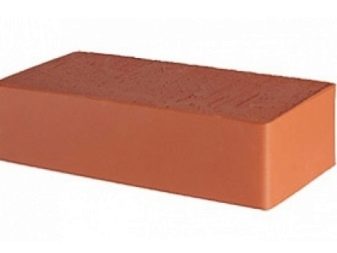

- In the composition of the clay there is such a component as iron, which is responsible for imparting a characteristic red color to the full-bodied brick.

- Brick is a fireproof material. It does not burn or support flames.

- The level of frost resistance of solid brick varies. Some types of building materials are suitable only for indoor placement (F25), while others are used for outdoor masonry (F50). The highest density bricks with the marking F150 are completely frost-resistant.

- The level of water absorption of corpulent bricks reaches about 13-15%. This characteristic of the building material is very important, as it has a direct impact on the frost resistance of products. The level of water absorption depends on the degree of density of the brick.

- High-quality solid brick lasts a long time and over the years does not lose its presentation.

- The characteristic quality of solid brick is excellent bearing capacity.

- The higher the density of solid brick, the higher sound and thermal insulation characteristics it possesses. For example, hollow products can not boast of such qualities - they miss the street noise and make the home more cold.

Many characteristics of solid brick depend on the raw materials that were used in its manufacture. Today on the market you can find several varieties of similar products. Each of them has its own positive and negative qualities that must be considered when purchasing.

Advantages and disadvantages

Solid brick is a very popular building material, which is addressed during a variety of works. Its popularity is due to the large number of advantages.

- Today on sale you can find a full-bodied product of various sizes. Due to this fact, consumers have the opportunity to make designs of various forms.

- Competently selected products have an attractive appearance. They may vary in color and texture.For example, a textured lining with imitation of a marble surface looks very interesting and impressive in different buildings. With the help of these materials it will be possible to impart a special style and high cost to the construction.

- Such materials can boast of high strength: they are not so easy to damage or break. In addition, it is permissible to construct both internal and external walls from solid brick, and both structures are reliable and sturdy.

- Solid bricks differ in heat capacity. The buildings in which the walls are made of these building materials remain quite warm and cozy in the winter, and in the summer they have a slight coolness.

- Body products are easier to install. To carry out such work there is no need for special knowledge, skills and rich experience. Even a beginner can cope with the installation of full-bodied parts if he follows the instructions.

- Another important advantage of solid brick is its environmental friendliness: this material is safe for both people and the environment. In its structure there are no hazardous and harmful substances that can damage health.

- It should be noted, and high noise insulation corpulent bricks. Houses built of these materials remain quiet - the extra noise from the street in them is almost imperceptible.

- Similar products are presented in the widest range. Buyers have the opportunity to purchase a variety of bricks for any construction work: from simple to very complex.

- These products also boast durability - they serve for quite a long time without losing an attractive appearance. Houses made of brick for many years remain aesthetic, if done correctly and from high quality raw materials.

- Due to its structure, solid brick is quite strong in compression and bending.

- Since there are practically no pores in such bricks, they absorb harmful moisture at a minimum.

- Solid products are resistant to low temperatures. This quality is especially important in Russia.

However, not everything is so rosy. Solid bricks also have a number of drawbacks that you need to be aware of before purchasing such materials.

- The walls of solid bricks must be additionally warmed. To do this, use different materials.It is impossible to neglect this stage of construction work.

- Such building materials have a large weight, so working with them is not so easy, and the transportation of such products can cost a lump sum.

- Solid bricks are much more expensive hollow versions, because in their manufacture you need more of the main component - clay.

- If you choose a full-bodied brick unsuitable brand, then it may begin to crumble.

- When shipped, such products are very easily damaged.

- On ceramic bricks often appear defects such as efflorescence. Externally, they are whitish divorce, spoiling the appearance of the material and structure as a whole.

As you can see, the advantages of this building material are much greater than the minuses. Much depends on the outlet in which the brick was purchased. In stores with a not very good reputation, you can stumble upon low-quality products, issued for first-class. With such materials there can be many problems in the future.

It is also important to work competently with such a brick - then the construction will be more reliable and of high quality.

Kinds

There are several varieties of solid brick. Each of them has its own performance characteristics.

If you start from the raw materials from which such bricks are made, some types can be distinguished.

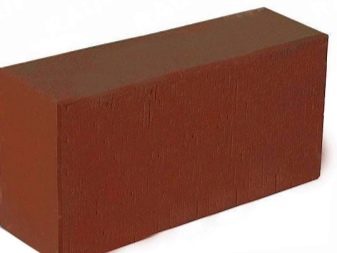

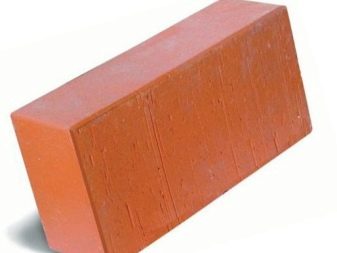

Ceramic

Such varieties of solid brick are the most common. They are made from clay, and sometimes from other types of raw materials. Ceramic products are characterized by a light and airy structure. They should not be external cracks or other similar defects.

Silicate

Silicate full-bodied bricks are the second most popular. Such options are made from a special mixture with lime and sand. Finished products have excellent sound insulation qualities and low thermal conductivity. Silicate options are thinner and lighter than ceramic. However, such products have a serious disadvantage - poor moisture resistance.

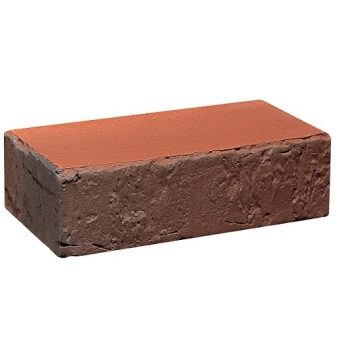

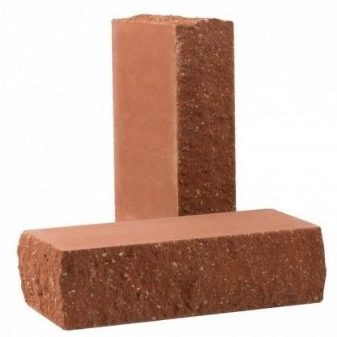

Hyperpress version is made from a combination of cement, limestone and a special dye. The resulting composition is subjected to pressing in a special form. The result is a blank in the form of bars of perfect color and shape.In most cases, this material is used in facing works.

Based on the purposes of further application, there are several more varieties of solid brick.

Standard (private)

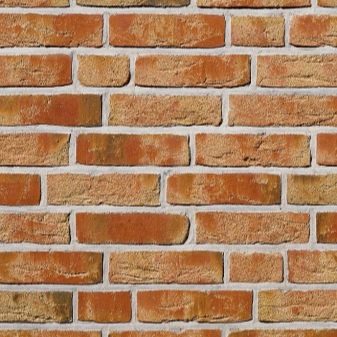

These subspecies of building materials are used in almost all areas. For example, it may be the manufacture of the foundation or the construction of the walls of the structure. It is permissible to finish such brick bases with paint or plaster mixture. Standard building materials have a heterogeneous structure and color. Often on such products you can notice defective areas, but they have no effect on the quality of bricks - they remain just as strong and reliable.

Facing

In most cases, this material is used for various finishing works. They have no defective surfaces, and the color is always uniform and neat.

Chamotte

Usually chamotte type of solid brick is used in the conduct of finishing, both inside and outside buildings. Often chamotte brick revets fireplaces or stoves. These building materials are characterized by high density, high weight and resistance to temperature fluctuations. Fireclay brick is able to withstand the effects of high temperatures (up to 1 thousand degrees).

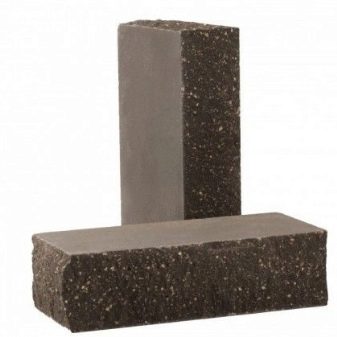

Clinker

The name of this building material comes from manufacturing technology, involving the sintering of several layers of clay to the formation of a homogeneous mass. Thanks to this procedure no defects appear on the brick - in this way products of different colors and textures are made. Otherwise the clinker brick is called paving.

Textured

In search of an attractive full-bodied product should pay attention to the beautiful textured options. Such products are distinguished by the fact that they have embossed patterns on the front. The analogue of the textured version is a shaped model (otherwise called figured or profile).

This option is ideal for the manufacture of structures with a complex structure. For example, it can be beautiful arches.

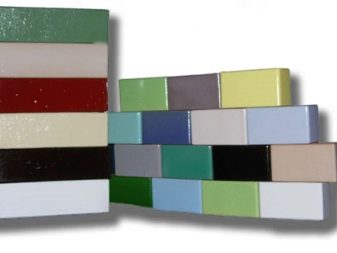

Glazed, Engobed

Such bricks are a kind of facing materials. For example, in the case of glazed products, the ceramic surface is supplemented with a special glaze, which is based on a special glass powder.The result is a very beautiful coating that attracts attention. And engobe is a mixture based on white clay. After passing the firing process, such products are complemented by a neat matte layer.

Facial

This type of brick is different in that all its sides have perfectly smooth and neat surfaces. In addition, such products are characterized by an ideal geometry. This type of brick is most often used for decoration of facade foundations, fences and simple decorative structures.

Facade

In such bricks, the front half is covered with a decorative finish, imitating various natural materials. For example, it can be a surface under a tree, marble or another stone.

By the production method, corpulent bricks are also divided into subgroups.

Plastic molding

These products are rightfully recognized as one of the most sought after. They differ in that they have no restrictions in use. They are made by pressing the raw material under high pressure. After that, the billet is dried and fired.

Semi-dry molding

Such types of corpulent bricks are made from standard raw materials - clay pressed in a special form. After this, the blanks are roasted, but not dried.This building material is characterized by a porous structure, which is why it is not suitable for all works. Usually, such a brick is acquired for work inside buildings, since for them high humidity can be destructive.

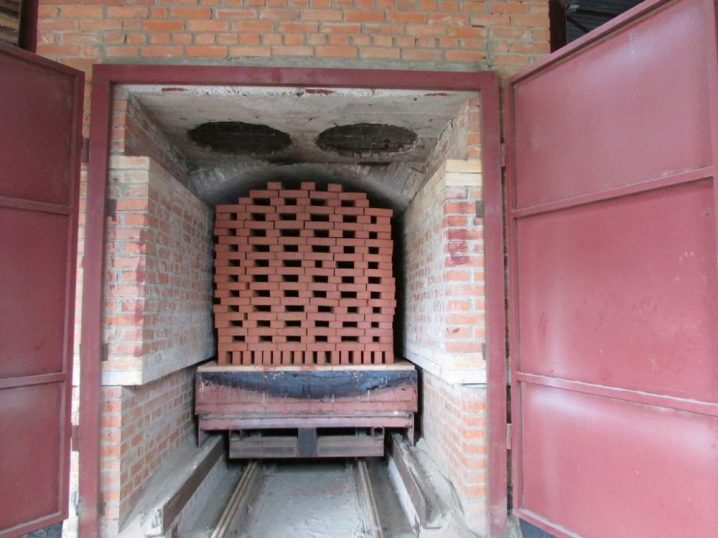

Ceramic products are:

- burned - such varieties undergo heat treatment in specialized ovens, after which they become more durable and strong;

- unfired - these bricks undergo natural drying, but they do not have the highest qualities of strength, and therefore are used in rare cases.

Also in different points of sale you can meet full-bodied bricks with different markings.

- M50 - this marking is affixed to materials intended for the manufacture of fences, partitions and other structures that are not designed for too serious loads.

- M75, M100 - These are bricks designed for the construction of load-bearing walls.

- M125 - such marking is affixed to solid bricks, which can be used to prepare the bearing wall and arched structures.

- M150, M175 - such building materials are ideal for the construction of foundation structures and plinths.

- M200 - material with high strength level, can be used almost everywhere.

- M250 - raw materials with such marking is ideal for the manufacture of supporting structures. It can also be used in the manufacture of exterior or interior wall foundations, basements, foundations, fireplaces and stoves.

- M300 - the brick of this brand is used in the construction of the foundation of low-rise buildings. These materials are designed for impressive loads and are characterized by high strength characteristics.

The higher the brand of building materials, the more impressive is their weight.

Dimensions and weight

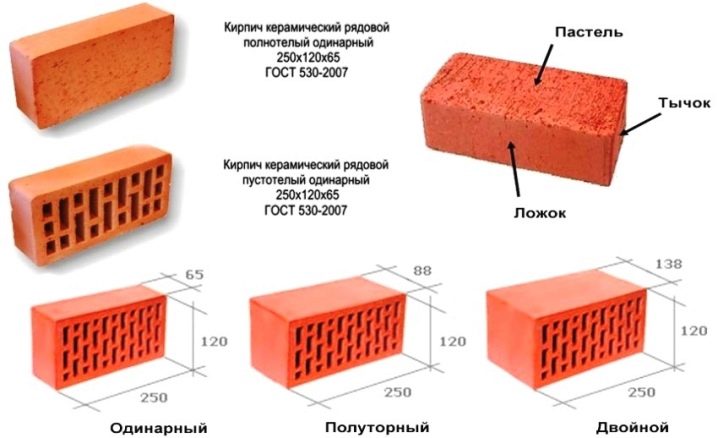

Modern products have different dimensional parameters and weight. On sale there are:

- single bricks - this type has dimensions 250x120x65 mm;

- one and a half items - dimensional parameters of these bricks make 250х120х88 mm .;

- double - the dimensions of these products reach 250x120x130 mm;

- Euro - The height of these bricks reaches 6.5 cm, and width - 8.5 cm;

- modular single - such building materials differ in length 28.8 cm and width 13.8 cm

Standard models include dimensions of 250x120x65 mm. The weight of such products reaches 4.3 kg. As for large-size wall building materials, their weight can reach up to 24 kg.In this case, everything depends on the direct dimensions of the solid brick - its width, length and height.

The most economical experts consider double ceramic specimens. Versions of the euro and modular used in construction work less often. It should also be borne in mind that the half and double models are more often made hollow. As for single bricks, their size is designed so that it is convenient to take them with one hand, and the second at this time to lay prepared in advance cement mortar.

Bastard and double bricks do not require a solution in a large volume, making masonry cheaper, but no less quality.

How is it made?

Today, corpulent bricks are produced by a special technology in several stages.

Before the immediate start of the manufacture of bricks suitable raw materials are selected. The selected mass is correctly prepared for further use.

Previously, raw materials such as clay will need to be slightly moistened using steam. It is necessary to achieve the maximum plastic consistency, so that it yields to the formation. Also removed from the composition of all hard and stony inclusions.

Then form a brick raw. This process is automatic in most circumstances. The tape with raw materials is cut by means of the special device on various preparations. Their dimensions, as a rule, are slightly larger than those of finished products, since after passing through all the production steps the clay noticeably shrinks.

The next step is the drying of the prepared semi-finished product. It is extremely important to follow the appropriate technology of the drying process. It is necessary gradually and without haste to solve the specified task. It is important to bear in mind that excessive acceleration of this process often provokes the cracking of bricks, and it is better not to use such material in construction work - it will be unreliable.

This is followed by firing the workpiece. It is carried out in conditions of specialized stoves. The temperature of heating in such conditions usually reaches 950-1000 degrees. At this stage of manufacturing it is very important to comply with all the requirements that are laid down in the process.

The method of semi-dry pressing involves the following steps:

- first, the clay, as in the previous version, is moistened to the required level, after which the raw material is processed into powder;

- the resulting mixture is poured into special molds, then to get the raw bricks;

- almost immediately after the forming stage, a similar semi-finished product is sent straight to the kiln for firing.

Silicate solid brick is made according to the technology described below.

- Raw materials prepared from sand, ground lime and water are mixed until a homogeneous mixture.

- The resulting mixture is kept up until the lime in it will not be fully extinguished.

- The next step is the composition is pressed into a brick under the action of high pressure. After that, the resulting semi-finished product is sent to specialized equipment. This process usually takes about 8-14 hours.

- Over the next 10-15 days, building materials are kept for the purpose of proper carbonization.

As for the popular fireclay bricks, it is produced by firing crushed refractory clay that has been pre-fired. In this case, the role of raw materials can be crushed defective ceramic products.

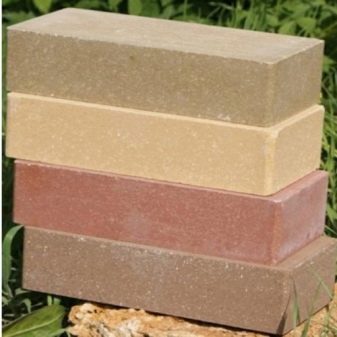

Color spectrum

You should not think that the color of full-grown bricks is limited to a red tint. It is necessary to take into account that the color of these building materials directly depends on the composition of the main raw material - clay.In most cases, after firing, this material acquires a standard brick color (characteristic shade). Such raw materials are called red-burning - it turns out red brick.

Much less often it is possible to meet the building materials made from white burning clay. Attractive, yellow, apricot and white bricks are obtained from this raw material.

Quite often, in the manufacture of corpulent bricks, raw materials are diluted with various pigment additives. For example, brown products can be obtained only if we turn to the addition of pigment components.

In accordance with GOST, a brick must necessarily fit the main sample, which is approved by the manufacturer of such building materials. Often in the factory there are several reference bricks. Because of this, there is a risk of acquiring an overly varied consignment of goods.

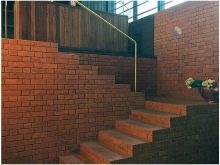

Scope of application

Solid brick is used in various fields. This building material has been very popular for quite some time. Currently, its production is at the highest level.

Solid brick is in demand not only because of the large number of positive characteristics, but also a wide field of use. This construction material can be safely addressed during the construction of virtually any buildings that need the strongest and most durable foundation that does not cause any problems. These facilities include:

- various base designs;

- basements of various sizes;

- base;

- columns of different dimensions;

- facing and bearing wall structures;

- high-rise buildings of any modifications;

- steps;

- chimneys;

- furnace structures;

- fireplaces;

- mine elevators.

As you can see, solid brick is permissible to use in a variety of workflows. All of these objects must be stable and strong, so for their preparation is required to select the right building materials, designed for impressive loads. Such requirements are met by high-quality full-bodied masonry bricks.

How to choose?

When choosing a high-quality solid brick, you need to focus on some important parameters.

You should consider the brand of selected products.It should be selected at the stage of drafting the future construction. To buy products with one or another marking should be based on the data specified in the project documentation. If you buy a brick of unsuitable brand, it can quickly fail.

It is imperative to request a certificate of quality for the selected product. This document should indicate that solid brick is fully consistent with GOST. The building materials brand is also mentioned there. If the certificate was denied, it is better to go to another store for bricks, otherwise you can purchase low-quality products.

Experts do not recommend buying bricks, the brand of which is below M75.

You need to carefully examine the bricks being picked up. They should not be cracked, chipped, scratched or stained (any - and light and dark), or other defects. It is worth remembering - it is impossible to buy such building materials with flaws, since they will not last long.

Experts recommend when choosing a brick to gently knock on its surface with a hammer or any iron part, and then pay attention to the sound being produced. It should be ringing, not deaf.

You also need to pay attention to the fact that all the bricks in the party had the same color. No detail should be significantly different from the rest of the shade or tone. Such elements often stand out sharply against the general background, spoiling the appearance of the erection or lining.

You should not save on the acquisition of this building material. Products with a suspiciously attractive price may turn out to be of poor quality. Of these products are unlikely to make good buildings.

Apply for the purchase of solid bricks need to proven retail outlets that have a good reputation in the city of residence. It is better not to buy such things in dubious shops and shops - they may turn out to be completely different in quality as the seller claims.

Tips and tricks

It should be borne in mind that sand-cement mortar for solid bricks must be movable. For its manufacture, 4 parts of sand are taken for 1 part of cement.

Do not neglect the insulation of buildings from such building materials. With such additions, the construction will be much warmer and more comfortable. If you abandon the installation of insulation, then you can notice a significant difference - in a house that is not insulated in this way, the coolness will always remain, and the rate of frost penetration may increase.

If it is planned to build one or another structure in a cold region, then it is better to purchase ceramic bricks with a high level of frost resistance. Silicate specimens can be used as decorative facing materials in combination with standard red elements.

Fireplaces and stoves should definitely be laid only with refractory bricks. If material is selected for finishing, then it is better to use an ordinary brick. If finishing is not planned, then the front or decorative material will be perfect.

You will learn more about solid brick in the following video.