Brick Laying Tools: Patterns and Tools

The formation of high-quality and reliable brickwork is not an easy task, but you can cope with it without the involvement of a team of experienced craftsmen. The main thing is to use suitable tools and fixtures in work, which will make installation easier and quicker.

Let us consider in more detail what templates and tools can be used when it comes to creating a brick building.

Purpose and features of devices

As with other construction works, it is common to use special tools and fixtures when creating masonry. Most of them are usually bought in specialized stores, but it is permissible to use self-made devices. Of course, the latter are more often addressed by more experienced masters who come across such works quite often.

Let us consider in more detail what standard tools exist, what their purpose is.

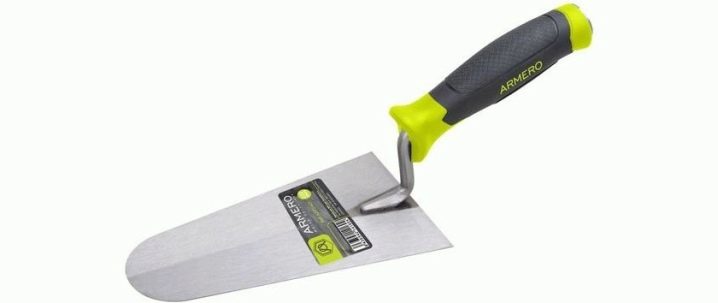

- Trowel (or trowel). This device is a compact blade with a flat surface for a more comfortable hold. It is necessary for laying the binder composition on brick blocks. Then this composition is neatly distributed by the trowel. With the help of this device are removed and the extra pieces of the solution.

- Patching. This device looks like a narrow groove fixed on the handle. The jointing is required for high-quality molding of seams, control over the level of their thickness, cleaning of excess pieces of the composition. The joints are convex and concave. In addition, when choosing this device, it is important to consider its profile.

- Small hammer. A well-chosen hammer will be required to trim brick parts to give them the required dimensional parameters and shapes. Also, with the help of this tool, it will be possible to correct minor inaccuracies of installation on a still un-fixed (or not fully fixed) binder solution.

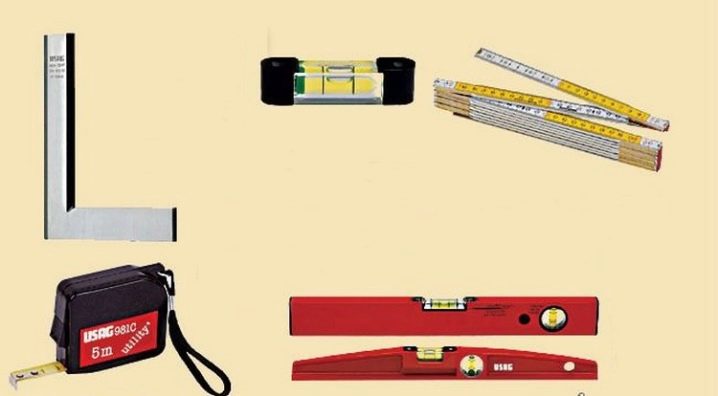

- Building level. Without this device, most construction work is not complete. The level allows you to check the horizontal or vertical base you are working with. The most popular are bubble and laser models. The latter, of course, cost more, but they are easier to use.

- Plummet. This device is a load in the form of a cone or bullet. It is attached to threads that do not have elasticity. Thanks to the plumb, the master has the opportunity to control the verticality of the structures being erected with respect to the displacement of the point of fixation of the thread in the horizontal section.

- Template, slats, rule and other devices that are necessary to control the conformity of the shape of the structure.

- Berth. This item is an inelastic high density thread.It stretches along the rows of brickwork and is used as a landmark of linearity.

- Order. Simply put, this is a large ruler, corresponding to the smallest width of a number of blocks.

- Cuvette. Otherwise, this tool is called the dispenser. It is a small tank without bottom. The walls in it can be both straight and beveled. With the use of the dispenser, it is possible to correctly measure the required amount of the binder solution for a specific section of the seam and immediately give it the required length and width.

- Dispenser-order. This is a cuvette, supplemented by mechanisms for marking. In addition, such devices are often distinguished by an adjustable measure of length and the presence of supporting mechanisms.

- Complex dispenser. Such an "assistant" consists of a level and other instrumentation. Also, it may contain additional components necessary for forming seams of the figure type.

With the help of a complex dispenser, masonry compositions can be leveled and held.

Template making

The template can be a very useful and effective device for the rapid laying of bricks. You can make it yourself.Of course, you can purchase ready-made models in the hardware store. As a rule, such products have the ability to adjust all dimensional parameters. If you want to save money, it is better to proceed to the independent production of the template.

First you should dwell on the basic geometrical parameters of the masonry joint (meaning height and width). In this case, much depends on the material used in the construction. Based on the technology of laying and used blocks, the dimensions of the pattern niche are revealed.

For the construction of the template you will need:

- a box of plastic of appropriate size (or a sheet of plywood);

- pencil;

- level;

- ruler;

- a drill (it is better to use an electric tool - it is more convenient and faster to work with it);

- fasteners;

- special corners of steel;

- screwdriver;

- screwdriver;

- hammer.

If you were able to find a suitable plastic box, then the template will be made much easier. In addition, plastic itself is a more durable and strong material, but it is light enough, which is very important when performing masonry work.If you haven’t found such a reservoir, you can make a model of the required dimensions yourself from laminated chipboard, plywood or battens.

First you need to build a simple box without a bottom. Its width should be slightly larger than the brickwork itself.

The design should consist of several main components.

- Frame with longitudinal walls of wood. The gap between the wooden planks should match the wall thickness. Since these strips will have prominent lower parts, it will be convenient to use them to align the bricks during laying.

- Handles for carrying. Thanks to these details it will be much easier and more convenient to use the device.

- Transverse parts. Basically they are made of special strip steel. This element allows you to keep control of the linearity of the masonry.

Patterns for masonry are also called dispensers, because with their help it is possible to properly measure the amount of mortar.

Mason's Toolkit

On the modern market of building materials and tools there are many practical and easy-to-use items, with the use of which the creation of brickwork is simplified many times.It is worth considering in more detail what tools are usually used by professional bricklayers when laying bricks, when making seams between individual blocks and for stretching a cord.

For brick laying

This category includes devices purchased for the preparation of wall foundations, as well as for lining brick facades. Without these devices, the bricklayer cannot work efficiently and effectively. In this case, a trowel, called a trowel, is considered indispensable. As mentioned earlier, it is a triangular spatula with a curved handle. The standard length of such a blade reaches approximately 18-19 cm.

Also the bricklayer needs a trowel for the brickwork. They are laid binder solution of the desired thickness on a brick base. In addition, the joints between the individual bricks are smeared with a trowel. They also remove the excess solution.

The trowel handle should be as comfortable and non-slip as possible to use it easily.

The second most important is hammer pickaxe. Its length is usually 30 cm.. One side of this tool can be set aside for tapping bricks so that the material will fit as closely as possible in the correct position, and the second - in order to prick bricks and hew.

A shovel for the solution is still fresh building composition is mixed to a uniform consistency. In addition, her mixture is placed on a wall base, if it is wider than 1 brick.

In addition, the bricklayer must keep the level of masonry under control so that it is perfectly flat.

For this use:

- level;

- plummet;

- gon;

- ordering.

To fill the seams

It doesn't matter if you are laying blocks for constructing walls, pillars, spiral arches or columns. In any case, you will need to competently handle the seams between the individual bricks, sealing them with special tools.

It is rather difficult to make the joints between the blocks an aesthetic look without the use of special devices. Usually for this use the jointing. The length of this device can reach 130-150 mm. As a rule, the jointing is a thin and narrow plate resembling a small knife.

With the use of jointing there is an opportunity to grind the joints of almost any type.

It can be:

- single cut;

- double cut;

- bulging;

- concave;

- joints in the trimming.

Based on the parameter of seam thickness, its structure and location, different sized joints can be used. They may also vary in cross-sectional profile.Also finishing and grouting of joints between individual bricks can be done with a trowel.

To stretch the cord

If we are talking about the process of laying brick blocks for the construction of the wall base, then first prepare the corner pieces. Only then collect the remaining elements of the structure.

The cord-wharf in this case allows you to lay out all the bricks, adhering to a single level. Basically, the cord is made from fishing line, capron or a very strong thread. Most often it is attached with ordinary nails to the masonry or immediately to order.

As a rule, the thread is stretched at a distance of about 2-3 m above the edge of the previous row. This is necessary so that there is no contact with the laid bricks in length.

Professional Tips

When selecting a trowel, one should keep in mind that there are two types of this tool:

- CB - options with a triangular blade;

- KP - devices with rounded corners and a pointed base.

To transfer the masonry composition with an ideally even layer of the required height can be difficult even for experienced craftsmen. That is why experts recommend using a special template.If you do not want to do it yourself, you can buy a ready-made version in the store.

Several templates can be used at once, especially if we are talking about the construction of a large object. In such conditions not only wooden, but also metal or plastic products can be used.

Already ready pattern can be used not only for laying out the correct rows of bricks, but also for laying different blocks, for example, aerated or slag.

In order for the dispenser of wood or plastic to "live" longer, damaged parts in it should be subjected to timely replacement.

Variants of wood should be treated with varnish, characterized by high wear resistance. For example, it can be an effective parquet composition. P

When you make a template yourself, you can prepare some simple drawings in advance. So it will be easier to create a structure. In the completion of the work, any tools should be well cleaned of residual solutions and mixtures. If this is not done, they will quickly fail.

Review the template for laying bricks, see the following video.