Slag stone: what it is, varieties and properties

Slag stone is one of the most popular building materials. They not only build houses from it, but also make reliable fences and partitions. Often cinder block is used in the construction of solid country cottages. Today we will take a closer look at this famous building material and its varieties.

What it is?

Slag stone is a popular building material, which is made using special shapes and vibropressing.

From such raw materials you can build a very strong and reliable house or use it in the construction of load-bearing walls.

Advantages and disadvantages

Slag stone is a building material that has established itself as one of the most practical, reliable and sturdy.Due to its impressive size (especially when compared with a conventional brick), such a unit significantly reduces the time to erect a particular building.

Today, this raw material is treated very often. Each consumer wants to purchase the highest quality and wear-resistant material for the construction of a residential building or an outhouse, therefore, the cinder block is in enviable demand.

At this stage, you should familiarize yourself with all the positive qualities of such products:

- One of the most important advantages of the cinder block is its fire safety. This material is not only non-flammable, but does not support combustion. That is why it is possible to apply to it without any doubts when it comes to the construction of a sauna or a country house.

- Slagblock buildings are very strong and reliable, so they are not afraid of any hurricanes or earthquakes. Of course, this feature also depends on the correctness of the construction work. In addition, such a block house will need to complement the high-quality reinforced belt. Steel rods together with the stability of cinder blocks will do their job - the structure will be very wear-resistant.

- To repair a dwelling built of cinder blocks, you will not need to spend a lot of time and effort. All work in such buildings are made in a short time.

- Many craftsmen prefer the cinder block, since any buildings from it are built very quickly. This is due to the impressive dimensions of the blocks.

- Even inexperienced home craftsmen, who had not experienced similar work before, can make cinder blocks.

- Slag stone is a versatile material. Many people use it not only for the construction of dwellings of various modifications. Arbors, barbecues and flower beds made of similar elements look interesting and are convenient to use.

- The buildings of cinder block can boast a long service life. On average, such block houses serve at least 100 years, without losing useful properties.

- Another advantage noted by many consumers in the reviews is the low cost of construction work using cinder block.

- Slagblock walls perfectly protect the premises from the penetration of excess noise from the street.

- This well-known building material is made from very different raw materials. Each consumer will be able to choose the right product.

- We should also highlight the decorative cinder block. This material can easily replace an expensive lining.

- At construction with use of slag stone a little cement mortar leaves.

- The weight of this block material is very small, since it is inferior in density to ordinary brick. Due to this quality, it is permissible to use cinder blocks in the construction of buildings on lightweight foundations.

- Slag stone is a material that is completely uninteresting to rodents. In addition, neither mold nor fungus appears on it. For this reason, this material does not need to be treated with protective agents or antiseptics.

- This material boasts good frost-resistant properties.

- It is possible to transport slag stones as in pallets, and just having accurately put it.

- Slag stone is a heat material. Thanks to this quality, houses built from such blocks are warm and comfortable.

- The forms of this material can be very different. Of them build structures of various modifications.

- Constructions of this material are not afraid of temperature drops.

- There are several options for cinder block. This means that suitable material can be selected for the construction of a variety of designs.

The advantages of the cinder block made it extremely popular among consumers.

However, this building material is not perfect.

Unfortunately, it has a lot of minuses:

- Not all types of cinder block are lightweight. There are also quite difficult options, which are not so easy to work with.

- If you can not get a beautiful decorative cinder block, then you need to be prepared for the fact that from the usual blocks of aesthetic and original walls just will not work. As a rule, they look dull and patterned.

- This material is recommended to protect from exposure to moisture and moisture. This is due to the fact that the cinder block quickly absorbs them into its structure. Over time, this often leads to their destruction.

- Some types of cinder blocks are not environmentally friendly due to their composition. The content of fresh slag contains a certain percentage of harmful substances.

- More attractive materials with a decorative structure are bad because they are hygroscopic. They must be protected from the effects of precipitation.

- Such material for construction complicates the process of laying cables and pipes. Because of this, during construction work, it is often necessary to turn to special equipment.

- It is not possible to build a tall building with several floors from the slag block. Too heavy structures can adversely affect the density and strength of materials.

- The construction of any buildings of their cinder block is distinguished by its technology. If it is not followed, the consequences could be dire.

- This material is not recommended to finish with plaster mix. Coating with this decorative material may cause the top layer of cinder blocks to peel off.

- These materials are characterized by imperfect geometry.

As you can see, the advantages of cinder blocks are still more than disadvantages. However, it can be noted that these materials are capricious and specific.

You need to work with them carefully and wisely. Otherwise, the result may disappoint you.

Specifications

Before proceeding to construction work involving slag stones, you should familiarize yourself with their basic characteristics.

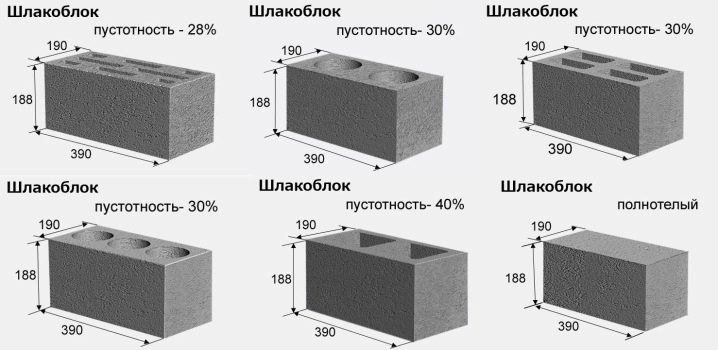

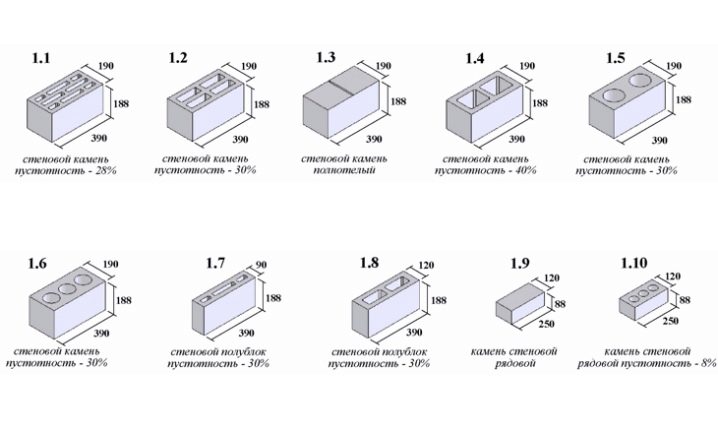

Standard dimensions of cinder blocks are 200x400 mm. There are materials with a parameter less than 200 mm - semi-blocks that are used in the construction of partitions.

There are two types of cinder blocks:

- hollow;

- monolithic.

These materials are characterized by their level of cavity volume:

- 2 rectangular cavities;

- 4 rectangular cavities;

- 2 or 3 round cavities;

- cavities in 3 rows, having an arbitrary shape.

To find out what density has a cinder block, you need to look at its brand. It is in the labeling of this building material that the load is contained, which it can withstand at 1 square meter. cm.

These materials do not differ in the highest carrying capacity. That is why they are not used in the construction of multi-storey buildings.

In addition, cinder blocks are characterized by high hygroscopicity, so it is allowed to contact them only if these requirements are met:

- It is necessary to start construction works only if there is dry weather outside.

- Laying should be done only on a high foundation (about 70 cm).

- The outer coating on the cinder block should be applied with a layer of 2 cm.To begin this work should be immediately after the completion of construction.

- In no case should a house of cinder blocks be left without a roof for a long time.

If we consider in more detail the parameters of the cinder block, then it is worth considering the following:

- The density of the blocks is 35-125 kg / cm2. If we are talking about materials labeled M125 or M100, then they make the foundation structures and walls of the basement. Materials marked M75 or M50 are used in the construction of walls / partitions. Stone brand M35 is used as a heater of a different material, which assumes the main load.

- Such a unit can safely “survive” 15-50 seasonal freeze / thaw cycles. This characteristic indicates excellent frost-resistant qualities of a building material. In order to serve the outer walls as long as possible, they are made of a 35-cycle cinder block with frost resistance. Buildings that will be in more severe conditions, as a rule, are built of stone with a given parameter of 50 cycles.

- Slag stone is thermally conductive. This characteristic is expressed in such parameters - 0.35-0.48 kW / m * ºС.

Different types of cinder blocks, which differ in their basic purpose, have certain dimensions and characteristics.

Consider them in more detail:

- A wall block (both empty and full) has the following standard dimensions: length - 390 mm, depth - 190 mm, height - 188 mm.

- Wall hollow so-called semi-block is available in two versions: 390x120x188 mm and 390x90x188 mm.

As for the weight of cinder blocks, everything depends on their structure and filling.

- corpulent options can weigh from 25 to 28 kg;

- hollow specimens usually weigh about 18–23 kg;

- the weight of the semi-blocks is 10-13 kg.

Composition

Do not think that in the content of modern slag blocks there is only such a component as slag. The name of this building material has long become conditional.

In the role of the filling ingredient in accordance with GOST any of the following components can be used:

- ash of volcanic origin;

- crushed granite;

- sand;

- broken glass / brick / concrete / solid cement;

- expanded clay;

- river gravel;

- gravel;

- sawdust;

- burning waste such as slag or ash.

It should be borne in mind that the performance characteristics and properties of this material depend on the components used in its production. So, corpulent elements are made from rubble, sand and pebbles.They are quite dense and heavy. Such materials will have excellent heat conductivity.

In order to prepare a lighter concrete mix, refer to components such as perlite, slag and expanded clay. From the resulting composition make elements with low weight and less effective thermal conductivity.

The introduction of sawdust will make it possible to produce an eco-friendly, heat-resistant, but fireproof block. However, it will have to be further protected from the effects of precipitation.

Kinds

There are several varieties of such blocks. Let's get acquainted closer with their properties and features.

Hollow and hollow

Both options are very popular in modern construction. Full-bodied slag stones are used in the construction of foundation foundations, various kinds of columns, supporting structures of various buildings, as well as ground floors. The main role is played by their strength characteristics.

Hollow cores are usually used to create walls and partitions of various buildings. They differ in modest weight, so we can safely say that they do not weigh down the structure at all.

Decorative Cladding

These building materials appeared on the market relatively recently. They differ in that they have a decorative coating. It can be either on one or on two sides. This layer of cinder block not only repeats various textures (for example, natural stone or plaster mix), but also additionally protects the building material, making it as resistant to moisture and dampness as possible.

Because of such equipment ceases to be a need for decoration.

Partitioning

These varieties of cinder blocks are addressed during the construction of partitions. They boast a number of advantages, for example, they allow you to form walls of perfectly correct geometry, save solution, are lightweight and can be installed very easily.

Colored

These types of cinder blocks are used on a par with simple materials. As a rule, it is to them that they are turned when making strong fences, gables or pillars. The required shade of cinder blocks is achieved at the stage of their creation. To do this, add crushed red brick or colored chalk to the composition.

Foundation

Otherwise, such materials are called artificial stone.It boasts excellent strength characteristics. In addition, the foundation cinder block boasts a very long service life. Over time, it not only does not shrink, but does not undergo destruction (does not crumble). If you are laying cinder blocks in a reliable foundation structure, then you need to remember about the presence of reinforced concrete tape. Its layer must be at least 1.5 cm.

Walls of foundation slag stones are in all cases supplemented with waterproofing and heat-insulating materials. In any case, it is impossible to neglect this stage.

Chipped and ragged

Relatively recently, interesting slag stones appeared on the building materials market, the surface of which is decorative and imitates a kind of “torn” or crushed brick. Typically, similar cinder block options are addressed for exterior cladding of fences or various buildings.

Slag blocks are divided by their immediate basis. So, the most common are materials based on slag, arbalite and expanded clay.

Based on slag

The quality characteristics of slag-based blocks directly depend on the properties and characteristics of the feedstock.This mainly concerns the environmental friendliness of materials (implies the presence of harmful toxic components in them). This parameter must be considered when choosing a cinder block. They differ in quite good heat-insulating qualities, and service life is same, as well as at a usual brick. However, we must bear in mind that the last parameter depends on the direct composition of the filling component.

If you make a choice in favor of high-quality blocks and subsequently correctly decorate them, then they will serve you for a very long time, and in many ways will surpass the brickwork.

On the basis of wood concrete

Special types of cinder blocks, based on an element such as arbalite, have excellent thermal insulation characteristics. However, keep in mind that these materials can not boast a long service life, which is a significant drawback. With the improvement of the last parameter, the environmental friendliness of materials usually decreases. This is due to the addition of special tools that affect the strength characteristics of the blocks. These components are not always environmentally friendly.

Based on claydite

Slag blocks, which are based on expanded clay, are considered environmentally friendly and safe. These building materials have excellent thermal insulation characteristics, coupled with a rather long service life. The advantages of such cinder blocks take place at all precisely expanded clay base. Such raw materials are lightweight, and in its structure there are natural voids in large quantities.

Most experts argue that expanded clay cinder blocks are the ideal choice of any master (both experienced and beginner). These statements are confirmed by statistical data - over 50% of European houses are built from such blocks.

Stamps

Choosing cinder blocks for any construction work, it is very important to pay attention to their marking. This indicator indicates the load that can withstand the unit. For example, a material having a mark with the designation “35” will seamlessly transfer loads that are no more than 35 kg per square meter. cm.

There are such brands of cinder blocks:

- M-35 kg / cm2;

- M-50 kg / cm2;

- M-75 kg / cm2;

- M-100 kg / cm2;

- M-125 kg / cm2.

Slag blocks, labeled "35", are usually purchased for the purpose of insulating other base material, which assumes the main load. Instances labeled M-50 and M-75 are often used to install walls and partitions. Blocks with the strength values of M-100 and M-125 are suitable materials for the manufacture of bases of various structures. In addition, they are suitable for the construction of foundations and supporting structures. From the above information it should be concluded that the greater the marking of the strength of the blocks, the more significant the load it can bear.

What is different from other materials?

Currently, block building materials are among the most popular and sought after. Buildings made of them are found with enviable periodicity. Today, there are many types of blocks, and many users are wondering what makes slag stones different from other options. We will try to answer this question.

From sand blocks and clay blocks

Peskobloki and expanded clay blocks are made in the same way as the cinder blocks. As for their environmental performance,here the latter are inferior to the sandy and expanded clay options, because the raw materials for their production are sand and expanded clay, which can boast of pure composition without any chemical and aggressive substances. Slag stones are usually made from various industrial wastes.

In addition, it should be noted that sand blocks and expanded clay blocks are not afraid of exposure to moisture and moisture, and also have good strength characteristics. Slag stones are inferior to them in these parameters.

From gas block and aerated concrete

It is also necessary to understand how slag stone differs from aerated concrete and gas block. In fact, the latest materials are identical. In their manufacture, an important point is the appropriate chemical reaction, providing a porous structure. Slag stones are made mechanically - by pressing.

Based on the parameters of these products, you can come to the following conclusions:

- cinder blocks are more dense, harder and stronger than gas blocks, but inferior to them in thermal properties;

- cinder blocks are less frost resistant than aerated concrete.

From foam blocks

Foam blocks today are sought-after materials, of which not only houses are built,but also all sorts of outbuildings. These materials in many ways are similar to cinder blocks.

Standard dimensional parameters of cinder blocks when laying are equal to 4-5 bricks, standard foam blocks can replace as many as 7-8 bricks. However, it is necessary to take into account the fact that the foam block is inferior in its value to cinder blocks. The same cannot be said about its thermal insulation characteristics and weight.

The foam block is more convenient and hassle-free in matters of transportation than the cinder block, and its installation is faster and easier. Otherwise, such a building material is called ecoblock. It has a higher strength factor than the slag version.

From brick

The lion's share of consumers is interested in, what is the cinder block different from the good old brick. It's no secret that the latter is terribly popular and has been used in construction for many years. In its performance characteristics and parameters, the cinder block is in many respects similar to a brick, and in some matters even surpasses it (this concerns strength properties).

Masonry bricks in rare cases have a strength mark of more than M-100. Slag blocks are also available with higher markings - M125 or M-150. In addition, it is impossible not to mention that it is very difficult to make a brick with your own hands (as a rule, it is almost impossible without appropriate knowledge and equipment), and it is quite possible to make cinder blocks on your own.

Useful tips

If you decide to build a house out of a cinder block, then you need to first build the strongest and tallest foundation possible. Experts recommend referring to tape options.

We must not forget that the cinder-block walls are very dense. Because of this, many craftsmen are faced with the problem of laying pipes and electrical wiring. As a rule, specialists in such cases refer to a special technique. That is why it is advisable to consider carrying out these works in advance if you are going to do this yourself.

When choosing this building material, always pay special attention to its filler. The best are the options with shell, claydite, sawdust and gravel. They are safe and environmentally friendly.

Be sure to verify the integrity of the cinder block in the process of their selection.In addition, you should pay attention to the identity of the geometry of several elements that are in different pallets.

Inspect the external walls of the cinder block before buying - they should be smooth. Also find out about storage conditions.

As for the transport of cinder blocks, it is most often used pallets. However, you can turn to simple storage. It is allowed to store blocks only on pallets. They should be placed under a canopy to protect from the damaging effects of various precipitation. Hollow elements should be put hollow down.

Experts say that the quality of the cinder block is quite possible to check with the usual 15 millimeter nail - Try to stick it with your own hands in the material below. If the nail enters it, it will indicate not the highest quality of the blocks.

Consider that the cinder blocks that were made without the use of a special vibratory machine, in their strength characteristics are much inferior to elements that were made with similar equipment. They are permissible to use only in the construction of plain non-residential premises.

If you decide to make cinder blocks yourself, you can always add certain missing components. The main thing is not to forget about the hardening time of raw materials, as well as the required proportions.

Slag blocks can not boast of high thermal insulation characteristics, such as, for example, the same foam blocks. Therefore, if you build a residential structure of these materials yourself, then you will have to pay special attention to the thickness of the seams. If they turn out to be too thick, the building will be cold - the heat will simply go through the seams to the outside.

Too thick layer of mortar (more than 1.5 cm) will negatively affect the insulating qualities of the walls.

If you decide to finish the cinder with plaster mix, then first you need to prepare them for carrying out these works. Otherwise, the plaster simply will not stick to the blocks.

Before proceeding with the construction of a building of cinder blocks, you need to correctly calculate their required number. To do this, calculate how many parts will be in 1 m3. For example, a material with parameters 390x190x188 mm can be calculated in this way: 39x19x18.8 = 13930; 1,000,000 (cube volume): 13,930 = 71. In 1 m3 there will be 71 block.

Do not save on the purchase of cinder blocks. Overly cheap materials can turn out to be of poor quality or even dangerous from an environmental point of view.

On the pros and cons of cinder block discussed in the next video.