Slag stones: standard sizes and area of use

Slag stone is a demanded material which is used both in residential and industrial construction. He has many positive characteristics that have made him incredibly popular.

Pros and cons of the material

Slag stone is a practical building material, which is produced using special shapes and vibrating devices with a press. Such a product is made not only in factory conditions, but also at home. Of course, in the latter case, quality products are obtained only with strict adherence to technology. The material presented today is quite common.

Its use is resorted to not only in the construction of ordinary residential buildings, but also in the construction of various kinds of outbuildings, from baths and sheds to original gazebos and flower beds.

The slag unit is characterized by the following positive qualities that have made it so popular in the modern market:

- One of the most important advantages of this material is that it is fireproof;

- the cinder block is not afraid of either high or low temperatures, even in the conditions of severe frost, such parts are not subjected to deformation or destruction;

- houses and other erections made of cinder block are durable and reliable; thus, a high-quality housing made of this material can easily serve for more than a century without losing the original appearance;

- cinder block constructions are easily repaired; Not only an experienced master, but also a beginner can easily cope with these works;

- the lion’s share of experienced builders advises to turn to this building material, since all the work is fast with it, due to the large block size and their relative compliance - if needed, the owners can easily correct such elements, for example, cut or cut off the extra parts;

- construction work with this material is usually inexpensive;

- even an inexperienced master, who has never come across such works, can cope with the laying of cinder block elements; moreover, you can build a house with your own hands from the cinder block, without having any special education;

- such materials are characterized by good sound insulation properties, due to this characteristic in cinder-block dwellings there is usually no excessive noise from outside;

- cinder blocks are made from different types of raw materials, thanks to this, each consumer can choose for himself a product that will serve without any problems in certain conditions;

- This material does not have a particularly attractive or rich appearance, although there is a special variety on the market - decorative cinder block; such details look expensive and aesthetically pleasing, so they are often used as cladding of various buildings;

- The slag block is an excellent choice for the construction of a private house, since it is not a “target” for rats, mice and various insects; Since parasites are not interested in this material, it does not need to be regularly treated with protective agents, such as antiseptics;

- this product is not subject to rotting, such as natural wood, which over time loses an attractive appearance and many positive qualities;

- Many consumers stop the choice on the cinder block, because it is characterized by heat capacity, the cinder block houses are very warm and hospitable;

- transportation of such materials is permissible to produce not only in special pallets, they are often simply put in a truck, without fear of the appearance of chips;

- some varieties of slag blocks have a low weight, because of which it is permissible to build structures made of such materials on lightweight foundations;

- Many buyers think that the cinder block can only be rectangular, but in fact today we can meet blocks with very different shapes; very original and eye-catching structures are made of them;

- such materials do not harm human health, and also do not cause allergic reactions;

- cinder block is not afraid of temperature fluctuations.

Professional builders strongly recommend that you familiarize yourself with all the minuses of slag blocks before proceeding to work directly with their use.

These include the following:

- not all types of cinder blocks have low weight, there are also very difficult options, work with which takes a lot of time and effort;

- if you want to spend money on the acquisition of an attractive decorative material, then you need to prepare for the fact that you can not make a simple construction of beautiful blocks;

- these blocks should be protected from contact with moisture and moisture, since they will penetrate into the structure of the material; over time, the dampness will accumulate in the blocks, and then lead to their separation and destruction;

- certain varieties of such blocks cannot be called environmentally friendly, since their content contains aggressive chemical components;

- when choosing an aesthetic decorative block, one must take into account the fact that it is distinguished by increased hygroscopicity;

- stacking shlakoblochnye walls, many masters are faced with the problem of laying communications; in the conduct of such work have to turn to special devices;

- tall multi-storey buildings cannot be built from these blocks;

- without finishing the foam block looks not too beautiful,therefore, it is usually finished; the owners may encounter another nuance - plaster or paint-and-lacquer mixtures cannot be laid on such materials due to the water absorption of the blocks; it is permissible to finish these bases only with specialized materials;

- the geometry of cinder blocks leaves much to be desired, because of this, when laying cinder-block walls, craftsmen often have to level their planes further;

- Units formed in non-industrial conditions may turn out to be of poor quality due to non-compliance with proportions or manufacturing techniques.

Kinds

There are several types of slag blocks on the building materials market.

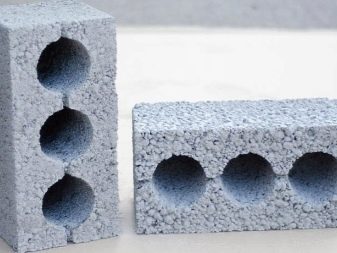

- Hollow and corpulent. These materials are used in construction with enviable regularity. So, full-bodied specimens can be used in the manufacture of foundations, columns, bearing structures and plinths. Blocks with voids are used in the construction of partitions and walls. Such products have a very small weight, so do not create serious loads on the base.

- Decorative. These types of cinder blocks are facing.They have occupied their niche in the building materials market quite recently, but they have already gained popularity among buyers due to their attractive appearance. On their surface there is a neat decorative coating imitating a stone or plaster. This addition not only makes the blocks more aesthetic, but also protects them from contact with dampness and moisture. Of course, such materials are more expensive than simple ones, but their quality justifies the price.

- The foundation. Blocks of this type are also called artificial stones. Such products have excellent strength characteristics. Moreover, these materials serve for a very long time. Over time, foundation cinder blocks do not shrink and do not deform.

- Partitioning. These types of cinder blocks are designed for laying partitions (hence the name). From these materials you can build smooth and neat walls of the correct geometry. At the same time, the consumption of cement mortar can not but rejoice the master. Such blocks are also distinguished by the fact that they are easy to use.

- Colored. These types of cinder blocks are used as often as the usual variants.However, they are often turned to in the manufacture of fences and columnar structures. This or that shade is given to these blocks even at the time of their manufacture. To this end, the solution is supplemented with crushed brick dust or colored chalk.

- Ripped and crushed. Recently, torn and crushed cinder blocks appeared on the market. Their surface is considered decorative, as it is an imitation of "torn" or chipped brick. These materials are used for lining due to the original look.

Slag blocks are separated by their basics.

There are several options.

- Slag. Slag-based materials are most common. They can boast of good thermal insulation qualities. Serve such blocks are capable of as much as a simple brick. But here it should be noted that the service life of these materials depends on their composition.

- Arbolitovye. Arbolit-based blocks also have excellent thermal insulation qualities, but they do not last as long as slag products, which is a rather serious drawback. If substances that prolong their durability are added to the composition of wood concrete blocks, then the materials become less environmentally friendly.

- Expanded clay. The most environmentally friendly blocks are rightfully recognized on the basis of expanded clay.Such materials are characterized by excellent thermal properties and a very long service life. The positive properties of such blocks are due to their expanded clay base, since in itself, expanded clay is a lightweight material, the structure of which has natural pores.

Today, experienced specialists recommend stopping their choice precisely on expanded clay slag blocks, which is explained not only by their environmental safety, but also by their unpretentiousness. Today, many homes in Europe are built from such elements.

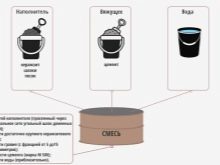

Composition

Many consumers are sure that slag is the main component in the composition of cinder blocks. However, it should be noted that the name of this material has long passed into the category of conditional.

The following materials can be used as a block filler:

- crushed granite;

- sand;

- river gravel;

- expanded clay;

- sawdust;

- slag;

- ash.

The properties and characteristics of cinder blocks are directly dependent on the components that are present in their composition. For example, corpulent parts are usually made from ingredients such as pebbles, rubble and sand. The result is dense and heavy materials.

In the preparation of lighter concrete solutions used perlite, slag, expanded clay. From such a base blocks with low weight and low thermal conductivity are obtained.

Dimensions and weight

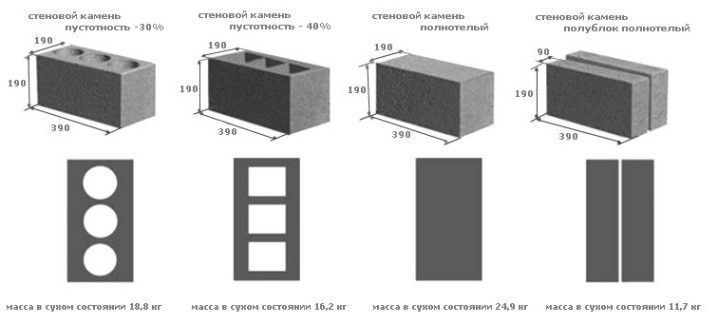

Standard sizes of typical slag blocks in accordance with GOST are as follows:

- 39 cm - length;

- 190 mm - width;

- 188 mm - height.

But do not think that in retail outlets you can find blocks that have only such dimensions. Materials of other sizes are also available, for example, 400x200x200 mm or 395x195x195 mm. There are special types of cinder blocks - semi-blocks. Usually from them stack partition structures. Standard sizes of these materials are 390x120x188 mm. DIY-made blocks can be significantly different in size from products manufactured on an industrial scale. For example, parts with dimensions of 300x140x140 mm are widely used.

As for the weight of slag blocks, then it is worth considering that the following features affect this parameter:

- fillers, which are available in blocks;

- direct internal structure of materials;

- solid or hollow block type.

The average weight of a corpulent cinder block (standard) is 25-28 kg. Hollow variants, on the other hand, can weigh 13-18 kg, and the weight of semi-blocks often varies in indications from 10 to 13 kg.

Scope of application

Slag stone is famous for its multitasking. This material is used in different areas and has a different purpose.

It is worth paying attention to the following examples:

- high-density products are used for the construction of residential buildings, while exterior walls are made of full-bodied parts in those buildings where more than 1 floor is present;

- apply this material and in the construction of baths; it is suitable for such buildings, as it is not afraid of fire and does not rot;

- from cinder blocks you can build a garage;

- these materials make reliable fences, for this purpose it is recommended to use only frost-resistant materials of high strength;

- foundation slag-block erections are simple in construction, and also serve for many years; the strength of such a foundation will depend on the specific type of soil on the site and on the number of floors of the future construction;

- most often this material is used for laying walls; so, for external structures, corpulent parts are usually used, or such blocks, in which the level of voidness is equal to 30%;

- many owners build cinder blocks of sheds on their sites; if the appearance of such a building does not play a special role, then absolutely any type of block (with any composition) is used for it;

- good arbours are obtained from cinder blocks; of course, people turn to such structures less often, since the classic gazebo should be more elegant and attractive, but cinder-block structures will turn out to be warmer and more stable; for such construction work, materials can be used in which the level of voidness is 40%;

- From the slag block, excellent basements are obtained;

- this material is permissible to use when erecting a rough base, and later to finish it with decorative materials;

- if there is a noticeable drop between the threshold of the house and the plane of the courtyard, then it can be laid out with a cinder block that will easily “smooth out” the drop; then it will be possible to trim the draft structure with tiles or porcelain stoneware - it all depends on the preferences of the owners;

- very few people know, but it is quite possible to build an outdoor toilet from a cinder block; as a rule, such structures are additionally insulated, so it is permissible to use any kind of block (even with a very low level of density);

- many consumers are wondering if it is possible to build a basin on the site from the cinder block; in fact, experts still advise pouring such structures with concrete, since slag elements absorb water and start to break down, it is better to make formwork out of such blocks;

- some home craftsmen make barbecues from slag blocks; It is recommended to make a site where fire will be divorced from refractory bricks, and lay the lower part in blocks;

- used slag stone is sometimes more expensive than new, as a rule, such materials were previously laid out using the correct technology and were manufactured at the factory; These types of slag blocks are permissible to use for the construction of cesspools.

On the pros and cons of cinder block, see the following video.