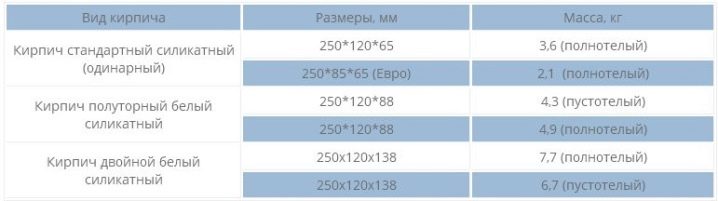

Dimensions and weight of standard sesquint silica brick

Silicate brick is made from quartz raw materials, in which lime and other substances are added, which improves the performance of the product. Initially, the brick is given the desired shape using a press in standard sizes, and then the workpiece is moved to an autoclave, where it is subjected to a pressure of 12 atmospheres. After this, the brick is treated with steam with a temperature of 200 degrees. The quality of the finished product depends on the correctness of these technological processes, and therefore it is important to monitor compliance with the parameters at each stage of production. The technological process averages 18 hours.

Brick features

The average weight of one silicate is 3-4 kg. Solid brick is used for the construction of buildings of not more than 3 floors in height. The density of each silicate brick is 1900 kg / cu. m. Also, the manufacturer can produce hollow stones, which have a lighter weight and lower density than conventional ones. This makes it possible to reduce the pressure on the foundation and to improve the heat insulation of the room, which allows preserving the heat-insulating qualities of the wall and reducing the degree of freezing of the structure with a smaller thickness.

In the hollow brick all the holes according to GOST 8394-73 are perpendicular. If necessary, bricks with other forms of voids can also be made. Such products are preferably used for the construction of multi-storey buildings, as they have good thermal insulation and low weight, which reduces the load on the foundation.

Weight measurement

By its gravity, silicate is similar to fireclay bricks. Some manufacturers may add iron oxide to the raw material for making bricks, as a result of which the product will look like an ordinary red brick. But you have to be careful when choosing.as this type of stones cannot be used for finishing fireplaces or stoves. With intense heating, they will crumble and turn into powder.

It is also important to know the weight of the brick, which is determined by the type of product. Depending on the use of silicate may be as follows.

- Private. It is used for simple laying and has rough sides. The presence of small chips on the surface.

- Facing. A decorative product that has a smooth and embossed surface and is distinguished by a large number of colors. The bricks should not be chipped or stained from the front sides.

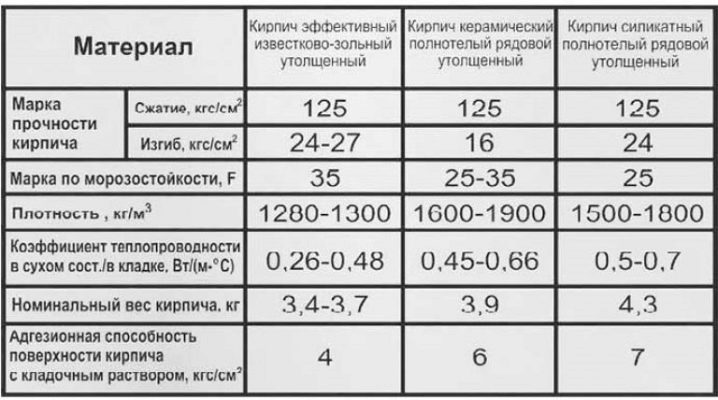

The weight of any body can be calculated in a certain form and produce such work yourself. Also in the calculations it is important to consider the presence of voids in the product and its humidity, which affects the weight characteristics. The proportion of standard silicate is 1300-1900 kg per cubic meter. Correctly made preliminary calculations will make it possible to find out how much weight will affect the base and to provide a reliable foundation that will withstand all the loads and will not allow the walls to crack during construction.Also, the manufacturer should always indicate the proportion of the finished product, which simplifies the calculations.

When choosing this brick, you must also remember about its strength, frost resistance and other properties. According to the degree of frost resistance, silicate is divided into grades. For the construction of external walls used brand F25. To increase the ability of a brick to withstand low temperatures, use special tools that repel liquids from its surface. Such compositions are applied to the face of the stones upon completion of the laying. This reduces the absorption of moisture and increases the frost resistance of bricks.

The strength of the stone is determined by the brand, which must also be considered when choosing. For example, the mark M75 is used for the construction of buildings with a height of not more than one floor. It is also assumed the possibility of the construction of them bearing walls with a small load. Mark M100 is suitable for the construction of objects in two or three floors. For tall buildings, a brick of strength M200 is used.

Distinguishes any silicate brick fire safetythat is ensured by the absence in it of components capable of igniting.The walls of this material must, in any case, additionally get rid of insulation. A disadvantage of silicate is a high rate of water absorption.

To know the weight of 1 cube of brick in a masonry, it is necessary to first determine the number of products in it. Experts note that in the cube of the masonry there are 414 single pieces, and the thickened one - 314. This number is approximate, since everything depends on the thickness of the seams and the type of masonry. For example, the average seam width is one and a half cm, and therefore this value should be added when calculating the number of bricks in one cubic meter of masonry. All data on which calculations are made, apply only to products manufactured according to GOST.

- The formula for calculating the number of bricks in a cube is 100x100x65 (88, 206).

- The formula for calculating weight in a masonry cube: 414 pcs. x 3-4 kg.

Knowing how many bricks are in one cubic meter of masonry, you can order the required quantity for an object and at the same time save money without buying excess material. It must be remembered that in each batch there may be defective products, and therefore it is recommended to add 5% to the required volume. If the construction of decorative elements on an object is intended, then another 15% should be added to the required volume.

The bricks to the object are usually delivered in packing, packaged in pallets, which contain one cube of brick. This allows developers to navigate in the calculations and order the required number of products. The sizes of silicate are standardized so that it is convenient to calculate their volume and number of units.

These bricks can be used for bearing bases, columns, pillars and other objects, and therefore, before buying, you need to decide on the type of masonry to be used. The choice of a product on thickness and other parameters depends on it. For example, single brick is usually used for the construction of load-bearing walls in buildings. To fill the voids, you can use the half-and-a-half bricks.

Also, when choosing this material, it is necessary to take into account the ability to absorb water, which reduces performance and reduces resistance to low temperatures. Therefore, it is not recommended to use such products without additional waterproofing in basements or other places where high humidity is observed. It must be remembered that silicate does not tolerate high temperatures, and therefore it is not recommended to use it near heating devices.

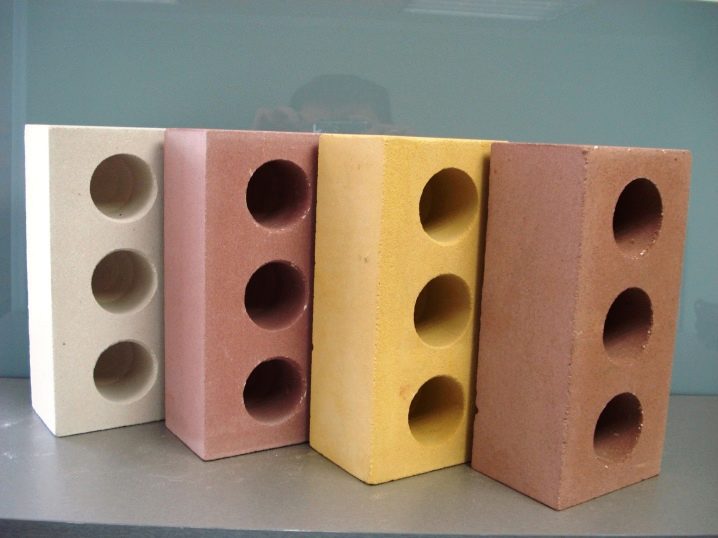

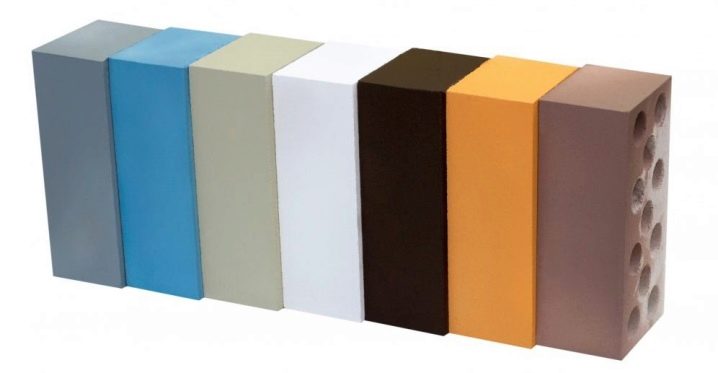

Through the use of modern technologies in the production of white brick, you can add in its composition various colors and change the color of the product depending on the needs. Today, such bricks can be orange, peach and other colors. If necessary, it is possible to order a color upon individual request. Coloring is made by pigments which are steady against an ultraviolet and rainfall, and then throughout all term of use the brick keeps the color.

Standard parameters

Building silicate stones are made rectangular and have standard dimensions:

- single - 250x120x65 mm;

- one and a half - 250x120x88 mm;

- double - 130x176x206 mm.

According to GOST, a deviation from the dimensions of not more than 5 mm is allowed. You should also consider the presence of marriage in the party. Non-standard products can also be used for rough laying or for building partitions.

According to the production technology today there is an opportunity to produce various types of silicate bricks, which are distinguished by their dimensions, parameters and characteristics. But the most popular are the main groups listed above.It should be remembered that the dimensions of the product do not determine its functional and direct purpose, but provide an opportunity only to determine the method and type of dressing during installation. Also in some cases, when using different types of bricks, you can speed up the work and save on them.

In practice, it is often necessary to use bricks of a larger size, and therefore in this case it is better to use one and a half bars, in which the width and length remain the same as the standard one, but the height is greater. This thickened brick is used depending on the required qualities of the surface and its hollowness. But when laying it is necessary to remember that the weight of such a product will be more. Often it is used to accelerate the laying, but working with it is inconvenient, since you have to lift more weight.

Silicate brick is an ecological material and has good characteristics.that allows you to use it everywhere. When buying any silicate product, you need to immediately determine what it is for, which will allow you to make the right choice.

You will learn about the pros and cons of silicate brick from the video.