Making a fence of bricks and corrugated their own hands

A beautiful fence and gate is the face of home ownership and the “outpost” of the protection and peaceful life of the owners, which is not visible to outsiders. Strong and reliable fence, besides perfectly fits into the surrounding landscape, this is the best result of the work of builders. Today, thanks to the technology developed over the years and modern materials, this task can be successfully solved with our own hands without the help of specialists.

Special features

There is a huge variety of fences and fences from various combinations of textures: monumental stone, light forged, eco-friendly wooden. Nowadays, a practical and durable combination of brick pillars and corrugated panels is very popular.

Benefits:

- This design has the strength due to the reinforced strip foundation, brick pillars, reinforced with a metal pipe, and lighter corrugated panels, which are mounted between the pillars, simplify the design, but they are also durable due to stiffeners, profiling.

- The life of such a fence is usually 25-50 years. All materials are resistant to aggressive environmental influences (precipitation, temperature changes, sun, mechanical loads), as well as environmentally safe.

- The materials used look good against the background of buildings made of brick or stone, the fence looks presentable and thorough. The range of textures and colors allows you to show creative imagination and impeccable taste.

- The professional sheet covers the territory of the household from the wind, the noise of passing cars, the curious glances of neighbors and passersby, from the penetration of foreign animals and people.

- The fence is affordable, it is possible to build it with your own hands, does not require the involvement of construction machinery, if necessary, repairs can be replaced by individual elements.

- The fence also reduces the noise coming from the street,in especially noisy areas, special noise-reflecting panels and strips are used, which can be attached to the upper part of the profiled sheet.

- You can combine sheets with other materials or use different textures of corrugated board, for example, wood imitation is indistinguishable from natural wooden inserts, but is not subject to rotting and deformation.

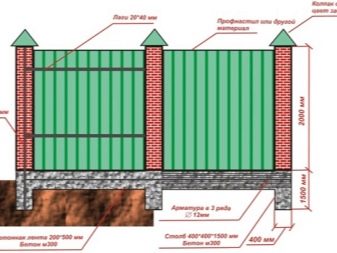

Constructions

It is important to choose the right design option, make a project, a drawing of the location on the ground and a plan for all phases of work, estimates.

There are building regulations that need to be considered:

- The fence should be within the boundaries of the land according to the documents.

- The distance between the brick pillars can not be more than 3 m.

- With differences in height, the fence line is divided into sections.

It is necessary to measure the length of the fence, divide it into sections, calculate the number of pillars and the universal distance between them. The height of the fence can take any up to 3 meters.

Options for constructive solutions:

- The pillars can be laid out in one and a half bricks from the front side and in one brick from the sides, and can be folded into two bricks. Inside the pillars are reinforced.

- Decking can close the supports of the fence, and can be mounted between them so that the pillars are visible.

- The lower part of the fence can be brick or monolithic concrete with the use of reinforcement or the foundation is made flush with the surface, then the panel of the profiled sheet is mounted on the entire height of the fence.

- To protect and increase the service life of the upper surface of the pillars closed caps. Caps can be metal, concrete, from other materials.

Decor

Today's variety of textures and colors of corrugated sheets can satisfy the most demanding client or designer. Smooth or textured surface, with imitation of brick and stone, wood of different breeds, natural materials, with various patterns, ornaments. You can choose a canvas with a photo print, apply any image, including 3D. The palette of colors and visual effects is also amazing. There are paints and coatings luminous, with thermal indication, electrical insulating.

The brick also has a variety of shapes, surface textures and colors. Classic facing red smooth brick looks strictly and is suitable for most homes.The combination of several shades of brown or beige will give a more modern look. Figured and embossed bricks give plenty of imagination and look elegant and unusual.

The poles can be laid out not even, but twisted, of course, this is a task for experienced masons, but the result looks impressive.

The foundation is decorated with bricks, metal in color with the rest of the elements, caps should also be combined in color with the whole structure. You can tint and the seams between bricks, for example, add soot to the solution and get a decorative black seams.

The monolith technology allows you to make complex configurations of the basement and the basement part of the fence: concrete podiums, projections and niches for ornamental plants and lighting elements. Additional lighting can also be built into the pillars. The fences, decorated with forged elements, lace strips with pointed tops welded to the upper border of the panel, look great.

Manufacturing

The project is ready, you can start construction.

To do this, you will need the following materials and tools:

- Brick, sand, crushed stone.

- Metal rods for reinforcement with a diameter of 5-6 mm.

- Board for the installation of formwork.

- Brand cement is not less than M300, and better than M400.

- Pipe or corner for the reinforcement of the middle pillars.

- For the frame you need a pipe 40x20x2 mm.

- Level, Plumb, Roulette.

- Hammer, nails, shovel, screwdriver.

- Welder

- Concrete mixer or drill with nozzle mixer.

At the corners of the fence, you need to drive pins and pull a nylon rope around the perimeter for marking. On the fence line it is necessary to level the surface, mark the places of future pillars and also drive in pegs, mark the locations of gates and wickets. Then you need to dig a trench under the strip foundation.

The depth of the trench is considered to be the freezing point of the soil. In regions it will be different, on average 60-80 cm. Under places with corrugated flooring, the depth can be reduced to 50 cm. The trench width is determined by the thickness of the pillars, 20-25 cm is enough.

The volume of excavated land will be approximately 3 m3. It is advisable to separate the fertile layer from the clay in order to pour it out in the garden, increasing the thickness of the fertilized soil. At the bottom of the trench we stamp a 5-cm layer of sand moistened with water, then 10 cm of crushed stone.

The second stage of the foundation arrangement is the formwork assembly. Usually formwork is done 10-15 cm below the surface.The formwork is knocked straight into the trench of the boards, reinforced by bridges and struts to prevent the formwork from deforming under the influence of the pressure of the solidifying concrete.

The foundation must be reinforced with steel rods 10 mm thick. To make the reinforcement completely immersed in the thickness of the concrete solution, it is necessary to install vertical rods every 1.5 m. Horizontal fasten wire or welding to the vertical every 10 cm height and not more than 5 cm from the base of the foundation, so that the reinforcement does not stick out and does not rust. Usually, the reinforcement is first fastened, and then the finished one is lowered into the trench.

Further, it is possible to install strictly vertically reinforcing pipes or a corner for brick pillars and fix them with boards inside the trench. The shape of the foundation is not strictly rectangular, but expanding downwards. Then the fence will be able to withstand the load of soil heaving without deforming.

The solution is kneaded in the proportions of cement and fine sand 1: 4 or to 1: 5, screenings or crushed stone are added, and then water is added until a thick mass is obtained. For the best quality of the solution, it is desirable to add 25-30 g of plasticizer, most often it is the most inexpensive liquid soap or dishwashing detergent. The trench bottom is moistened with water, then the mixed solution is poured into the formwork.To build strength and proper drying of the foundation, it is moistened every day with water and covered with plastic wrap to avoid cracking.

Full drying occurs in 2 weeks, but the layer gains half the strength after 5 days.

Waterproofing is laid on the finished foundation, most often waterproofing or roofing material so that the brick does not absorb moisture from the soil and does not deteriorate for longer. The next stage of construction is the laying of bricks around the reinforcement pipes, the result will be reliable and even pillars. The laying is made with bandaging for reliability in one and a half or two bricks. Standard seam is 8-10 mm.

Every second row is reinforced additionally with steel mesh. At the levels of fixing the profiled sheet to the vertical pipes are embedded mortgages for the subsequent installation of the frame and profiled sheet. At the top point, in the middle and at the bottom of the pillar.

On the lined pillars mounted on top of special caps made of concrete or metal. They are painted in different tones with mineral dyes that are resistant to fading, may have a decorative finish.

Caps perform a protective function, preventing the ingress of moisture into the thickness of the pillars, as well as give a complete and decorative look to the fence.

Installation

To mount the frame for fixing panels of corrugated board, you need to weld the fixings that will stick up on the sides of the post: at the top, middle and bottom, at the laying stage of the posts, then you can attach the frame from the profile pipe at these three points.

The pipe should be marked and cut into pieces, the length of which is equal to the length of the span between the columns, with the help of level, set strictly horizontally, and weld the ends to the fixings using arc welding. As a result, you get three guide tubes, which are necessarily covered with alkyd enamel to avoid corrosion.

If the pipes are already rusty, treatment with a liquid converter is necessary.

Now it is possible to mount profiled sheets. To do this, you need to buy or cut sheets of the required size, mark with a marker the points of fastening of the floor sheeting to the frame, usually at a distance of one wave. Thus, for every meter there are 6 places for fastening, you will need 6 galvanized roofing screws and 6 rubber gaskets for screws.

When installing, the finished foundation is covered with cardboard in order to prevent the bottom edge of the panel from being stripped.At low speeds, the drill is fastened with self-tapping screws and rubber panels are used to finish the panels, joining the sheets with overlapping if necessary.

The result was a combined fence, reliable and presentable. With the observance of the terms of drying, it takes on average 2 weeks for all stages of construction, and it will serve faithfully for its owners for many years. Care for the fence is easy, just wash it with a simple means, pouring water from a hose. The design is such that it is possible to replace, if necessary, individual elements.

Beautiful examples

The combination of red brick and a maroon profiled sheet with a smooth front surface looks very harmonious. The foundation is also lined with brick and decorated with burgundy metal. The pillars in this variant are visible and make up the contrast panels, forming a strict and neat build.

In order to fit the fence into the surrounding landscape and give additional decoration, designers often provide niches and podiums for planting flowers or climbing plants, these are classics of style and manifestation of impeccable taste of the owner.

The process of building a fence can be viewed below.