Fence from a professional flooring: subtleties of production

Today, more and more owners of private houses are building fences of metal profiled sheet on their plots. And this is not surprising - this durable and reliable material quickly gained popularity among the people. Independently build such a fence is easy. All the subtleties and nuances of this work can be found in this article.

Special features

The fence from a professional flooring can be put on a site according to the drawing without appeal to professional builders and rent of special equipment. This and other factors make it very popular among owners of private homes.

Benefits

- Wear resistance. A fence made of profiled steel sheet will last for many years, as the material does not change its characteristics over time.It is reliably protected from corrosion by a special coating and resistant to strong wind gusts.

- Efficiency. According to the ratio "price - quality" profiled can be called the best for the manufacture of fences.

- Ease of installation. Almost any summer resident will cope with the features of the device of such a fence as quickly as possible.

- It does not require special care. Sometimes it is enough to simply wash the fence with plain water and, if necessary, replace individual sheets.

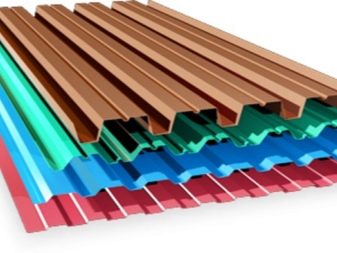

- Large selection of colors.

- Reduces noise. Decking able to reflect the sound waves.

- Aesthetic appearance.

Buying professional sheets, you should pay attention to the price. Too low cost may indicate a poor quality of galvanizing or not enough thick metal, which is not suitable for the construction of the fence.

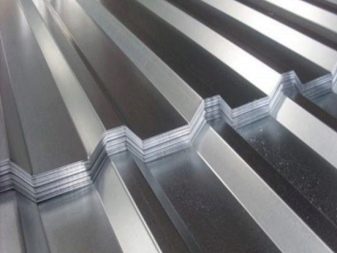

First you need to check the thickness of the sheet (for the construction of the fence is enough figure of 0.6-0.7 mm). Then you need to make sure that the seller has certificates confirming the quality of the material.

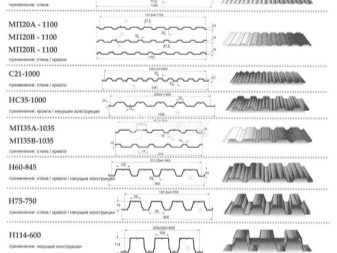

For fences most often used wall profiled. It is cheaper than carrying and suitable for any terrain without strong wind loads.It is important to find the optimal balance between price and sheet protection from external influences. Do not forget that the cheapest option in any case loses in durability.

The material has many layers, each of which serves a separate purpose. Of course, only the right combination of them makes the flooring really high quality. For example, a low grade steel coating will not have the desired effect. To stay on a particular material, you need to know what steel is covered with.

Varieties of protective coatings corrugated.

- Zinc. The cheapest option, the reliability of which does not have to hope. It is rarely used for the construction of fences in the suburban areas, but it is popular in warehouses, construction sites and industrial enterprises as a temporary fence.

- Aluzink. This is a coating of aluminum and zinc. Externally, this fence will be more presentable, besides it can be covered with acrylic or oil paints for metal. But the final cost will be rather big, considering the cost of high-quality paints.

- Polyester. The glossy surface of such a fence will always look neat, and any dirt is easily washed off with rain or water from a garden hose.The coating is resistant to any weather conditions and solvents are not afraid of it.

- Plastizol. The most expensive and at the same time the most reliable option. Often it can be seen in elite buildings. The fence with plastisol coating will stand for decades and look like new throughout this time.

Particular attention should be paid to the thickness of the sheet. If it is less than 0.45 mm, then the fence under the wind can easily be deformed and tear openings for screws.

It is about the thickness of the galvanized sheet in its original form, without a protective coating.

To avoid problems with the choice and not stumble on poor-quality material, it is better to order decking in Europe. There are concentrated leading manufacturers of world renown.

Constructions

Before construction, it is important to decide what construction will be the fence. There is little choice: the bottom edge can be buried in the ground or be above the ground. The distance between the fence and the ground is a prerequisite if the construction is carried out on a slope or on excessively wet soil.

It is also worth remembering that the wind and dust will gradually erase the protective layer of corrugated flooring and will need to be tinted to avoid rust.

But there is another way - to install special U-shaped profiles on the fence for protection.They, too, will need to be tinted every few years, but it is much easier than dealing with rust on the fence itself.

If the supports are round pillars of brick or wood, the fence frame should be mounted with overlap, i.e., by welding the lag and surface of the pillars, and the sheets are fastened exclusively to the lags. In the same way you can assemble the frame and on rectangular supports. Professional developers often do.

But for greater strength it is useful to fix the lags in the space between the supports in such a way that their external parts coincide. With this method of assembly, the sheets can be fastened both to the supports and to the logs. Screws, of course, in this case will need more, but the strength of the structure will increase many times.

There is also a so-called modular (sectional) fence - each professional sheet is framed by a frame around the perimeter, and then welded to the supports. This option is very time consuming, but in the end such a fence will look more stylish and complete than the usual metal.

Calculation of materials

Profiled - fairly durable material, and from it you can build fences up to eight meters.Metal is mounted on the logs, which are often two or three. For mounting also need metal screws.

In order to calculate the number of supports you need, you need to divide the length of the fence perimeter into gaps between the supports. To the resulting number, add 4 (two columns at the edges of the gate and for fastening the gate) and 4 more for each corner.

The amount of sheeting is considered based on the width of the sheets. Again, the fence perimeter should be divided by the width of the chosen professional sheets. It is recommended to take a couple of sheets more in case the calculations give an error.

To get the desired length of the lag, you must multiply the perimeter by 2, and add the required footage to the result for installing the gate and the wicket.

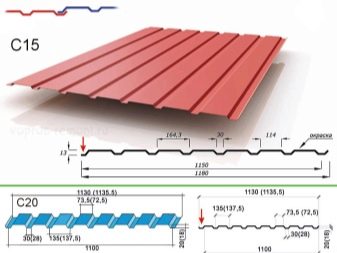

To make it easier to mount the fence, you can immediately order the sheets of the desired size. Their standard width is about 120-130 cm, and the height is 190-200 cm. You will also need metal screws, paint (if necessary), gravel and cement.

The method of installing supports, the thickness of the profiled sheet, the size (number) of doors and gates, the number of pillars and the lag may affect the final cost of the fence.

Preparatory work

Step-by-step instruction of preliminary works before the start of construction involves the implementation of several stages.

Markup

The first step is to decide where the fence will be located exactly (gate, wicket) and mark the place for the pillars. It is also necessary to decide what the height will be in order to correctly calculate the amount of material at purchase.

Selection of material for pillars

Most often, metal pipes are used as supports. The thickness of their walls should be at least 2 mm, for high buildings - at least 3 mm. Between round and shaped pipes, it is better to choose the latter, since they are characterized by increased mechanical strength. The height of the supports depends on the height of the fence, and under the ground metal is often placed half a meter. Over time, metal supports must be treated with anti-corrosion compounds.

If you want to save money, you can choose wooden posts for the supports. They are not as durable as metal, but will cost much less. In this case, the most suitable species are spruce, cedar or pine. It is important to choose a timber without cracks, with a smooth surface, otherwise repair may soon be necessary.Before you put the pillars in the ground, they must be treated with antiseptic and water-repellent mixture.

An alternative to wooden and metal supports can be concrete structures. Such pillars are made of cement, rubble and sand and have high strength.

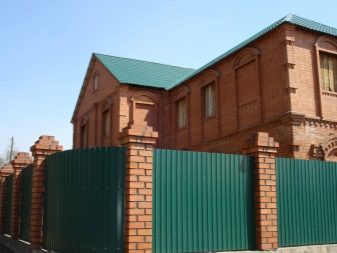

Sometimes the foundation of the fence is made of brick, which looks more advantageous. But building a fence with brick supports will require a lot of time and effort.

Installation of supports

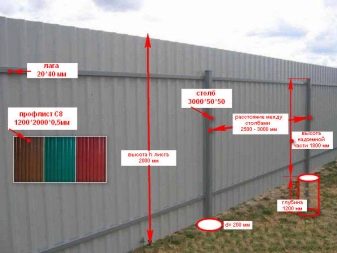

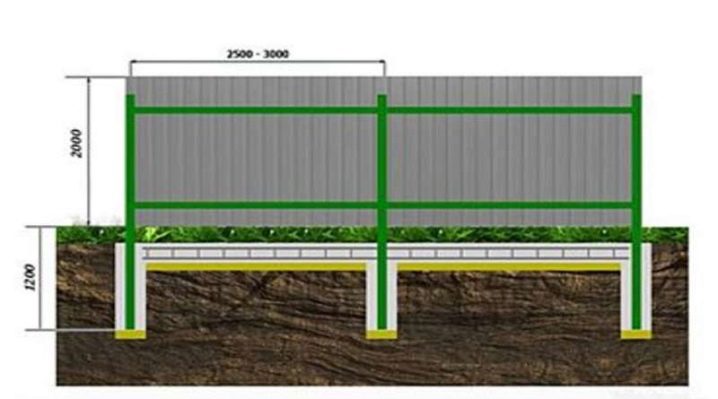

When the issue with the choice of material is resolved, you should proceed to the direct installation of supports. Here the most easy and reliable option would be a fence with columns of concrete. The standard indentation between the pillars is a distance of 3 meters. The fact is that the profile pipes are 6 meters in length and with spans of 3 meters it will be much easier to join logs.

Next, in the right places with the help of a drill, you need to make holes that will be at least 10 cm wider than the chosen supports. Gravel will be poured into these holes, which should be properly sealed. Then the supports are inserted and aligned.

Filling the holes with gravel to about the middle, you can start pouring cement.The post must be well fixed with boards or braces, which can be removed only after the mortar has completely hardened.

Fabrication and installation

When the foundation is completely frozen, lags can be set. There will need a six-meter pipe, which was mentioned earlier. The amount of lag varies from 2 to 3, depending on how high the fence is. Lags are installed at a universal distance from the edge - 4-5 cm. For reliable fixation, it is better to weld them.

To avoid rust, the posts are covered with a primer. If the soil on the site is soft, then the pillars with time can quickly subside. Therefore, in this case it would be logical to make a strip foundation. It is easy to install with your own hands - a ditch is dug out exactly along the pillars and a low tape box is built, then waterproofing is laid along the walls of the structure and all this is poured with concrete.

The next step is to install the metal profile on the logs. In order to firmly attach them, it will suffice to be ordinary metal screws. The joining of sheets of metal profiles is overlapped. It is necessary to mount in construction gloves, since.there is a danger of cutting yourself on the corners of the flooring.

The last and most laborious will be the installation of the gate and the gate. For them, you need to build a frame. At the same time, it is necessary to prevent sagging of the gate leaves by welding a separate strip to each of them, which will connect the opposite edges of the frames. After fastening the frame is sheathed on top of the profiling.

Important features to consider during construction.

- To prevent the final construction from squinting, it is very important to follow the vertical position with a plumb when installing the pillars.

- The distance between the supports is better not to do more than 2.5-3 meters, because otherwise the effect of sail can be created.

- Fence of corrugated can begin to build at any time of the year. Its further properties will not be affected by the weather and air temperature.

- If during installation the sheets are slightly damaged or scratched, you need to immediately paint over all the damage. In the opposite case, decking will lose its anti-corrosion properties.

Between the pillars on which the gate or gate will be installed, you need to dig a trench up to 30 cm wide, lay the armature frame inside and pour concrete on top.This is necessary so that the pillars are interconnected by one foundation and the influence of weather conditions is the same on both sides of the gate (gate).

Such a design will avoid misalignment of the valves and they will open / close freely. For pillars, which are intended to impose a brick, this design is required.

If the site is located on a slope, it is not at all a problem for the construction of a fence made of corrugated flooring, there are just a couple of features that should be taken into account during construction. For the evenness of the structure you need to stretch the rope around the perimeter of the building. Focusing on it, professional sheets are attached in such a way as to prevent differences in height between them. It turns out that each leaf has a slight deviation from the vertical relative to the ground, but on a small slope it will be almost imperceptible.

If the fence is erected on a steep slope with large differences in height, then another technology is needed. In this case, the line for installation is determined using a rope, plumb and construction level. It is necessary to measure the height of the difference between the pillars. To calculate the number of supports in this case, the height of the differences is divided by the indicator of the spans between the supports.

For example, if you plan to collect a length of 30 meters with spans between supports of 3 meters, and the difference is about 1 meter, then you need 10 centimeters divided by the number of spans, i.e. 10. We get the result of 10 centimeters. It is for this value that each of the spans must be made lower, which will preserve the aesthetic appearance of the building. The result is a kind of ladder, which gradually goes down the slope.

If the slope is very steep, you can install professional sheets of different sizes for each span. Thus, it will not be the most beautiful option, but at least the differences between the sheets will not be very noticeable and the fence will look more solid.

Combined structures with stone or brick supports require special attention to the condition of the soil at the site of the proposed construction. A problem for the construction can be soils that retain moisture. This property of the earth can lead to a sharp rise in the level of the soil when the soil freezes and, as a result, to the destruction of the entire foundation.

There are several ways to solve this problem.

- You can remove the entire soil at the level of freezing and replace it with another soil.This should be done with the ground around the foundation.

- You can set the foundation below the level of freezing, but in this case, the wet soil will put pressure on the base.

- There is also the option of warming the foundation with a special material for the entire depth of soil freezing. But this method is only suitable for light buildings.

- The best option is to install a drainage in the form of a trench with a pipe that needs to be wrapped in filter matter. This drainage is erected at a distance of about 40 centimeters from the fence, and the final structure is filled with rubble.

As you can see, the fence of corrugated can be built in the shortest possible time and be sure that it will stand for many years. If the concrete pillars do not look very aesthetically pleasing, there are plenty of ways to make the fence more attractive and stylish.

Decor

Originally the professional flooring was made as material for finishing of warehouses, temporary construction projects, parkings. That is, buildings that do not have an attractive appearance. Today, the professional sheet has become very popular, so manufacturers had to think about the colors and options for its decor.

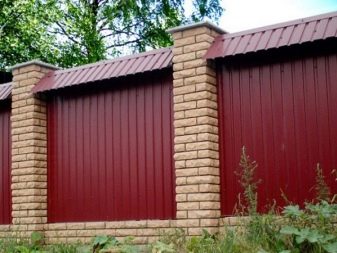

The most common way to decor - a combination of corrugated with brick or stone supports. You can also decorate concrete pillars with artificial stone or buy professional sheets painted under wood or stone.

The color of the fence should not be too cool to stand out from the design of the remaining buildings and the entire site. Some gardeners choose decking the same color as the roof. For the decoration of steel elements, it is better to use powder paint, which does not burn out or crack.

The technology of plasma cutting allows making curly cutting on professional sheets. Often the owners are limited to the figured design of the upper edge of the fence.

Many decorate their fences with forged items. It can be geometric shapes, patterns, ornaments and everything that is enough imagination. They can be welded or simply screwed to the corrugated board. Especially advantageous, these elements will look if these are already present in the decoration of the balcony, stairs or gates.

In the presence of facade paints, you can make your fence one of a kind. You can draw your favorite scenes, flowers, abstraction.And even better to hire a professional artist to depict a reproduction of classical painting. After drying, such a pattern should be varnished so that it does not crack and does not fade with time.

Well, the classic version of decoration - climbers, is always relevant. Often, greenery helps a pair of small mounts on the fence grow in the right direction, leaving only the gate and the gate free.

Useful tips

- If suddenly during installation the sheets of corrugated flooring were scratched with screws or something else, it is worth painting the damage with a spray can as quickly as possible.

- Without at least a minimal experience it is not worth taking up a welding machine. It is better to invite a professional or use alternative mounting methods without welding.

- If the parapets (ebb) of the fence are left open, then moisture will constantly get into small cracks in the material. When temperature drops this moisture alternately freezes and thaws, which can lead to the expansion of cracks and the subsequent destruction of concrete.

- Mandatory step is the waterproofing holes. Especially if the groundwater level is above average.Ruberoid is well suited for this purpose.

- If the corrugated sheets on the inside will be very dark, the area will visually appear smaller.

- The sheets should be joined in such a way that the corrugated sections are arranged vertically. Sometimes they are intentionally set horizontally, but in this case it is worthwhile to take care that moisture does not accumulate in the grooves.

- Sand poured in before filling the foundation will protect against uneven ground freezing in winter.

- Welds should be degreased and painted in the same color as the pillars and wicket. Otherwise, the seams may rust quickly.

- The work will go faster and easier if you immediately and correctly install the first sheet. The standard distance between the screws can be called three waves on the professional sheet. Thus, 10-12 screws are used for one sheet.

- For additional protection against moisture and give the construction of completeness, you can set the wind strip.

- When the columns are installed, you need to once again make sure that their location is even. To do this, take a thick thread and stretch it along the entire fence, securing it for the first and last pillar.

- Some self-taught builders simply hammer supports into the ground and professional sheets fasten on them. It is impossible to do this in any way, because without a planned basis, a fence in a couple of years can fall from a simple gust of wind. So that such improvisation in construction does not turn into complete destruction, you should immediately turn to professionals.

- For fixing the lag is used as a welding machine, and bolts. Experts advise to choose the first option. The total cost of the project will not change, but the strength will significantly increase.

- To avoid deformation of the sheets, you need to provide the correct distance between the edge and the lags. It will be optimal if it does not exceed 40 mm.

- Galvanized screws are necessary for fastening profiled sheets. The use of aluminum mounts can lead to cracks on the mounts in the cold and subsequently to the destruction of the entire fence.

- The choice of materials for the future fence is completely dependent on the owners of the site and can greatly affect the final result and service life. If dubious material catches your eye at a low price, it is better not to take it.After all, the desire to save money at the initial stage of construction can lead to additional expenses for repairs or even the need to completely redo the fence.

- If financial opportunities allow you to purchase a profiled sheet with a double-sided protective coating, then it would be logical to do so. After all, this option will be much more reliable and durable than the usual decking with one-sided protection. Such an investment will allow less frequent repairs to the structure.

- When painting sheets, application of several layers will be optimal. This is due to the fact that after mounting certain areas will no longer be available for painting, and additional protection will never hurt.

- It is clear that supports made of brick or stone will look much more attractive than metal pipes. But the latter is still used most often. This is due to the ease of self-installation and the ability to establish a lightweight foundation.

- When decorating, it is not worth being limited to identical sheets of the same color. With the right approach, you can combine multi-colored sheets with different corrugations and stone or brick supports.

- For registration with the help of plants you can plant grapes, ivy or other breeds that can grow on the fence.

- Also, more bulky plants are often planted around the perimeter - spruce trees, garden bushes, or they install large flowerpots in which ornamental trees grow.

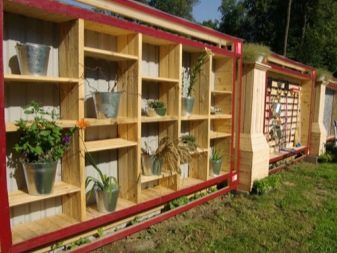

- The interior decoration of the fence can include various shelves on which you can put pots with curly flowers or just hooks on which decorative objects for the yard and garden are hung. In addition to decorations, household items or garden tools can be stored on such shelves.

- Often the question arises about how to close the space under the fence in the presence of strip footing. This can be done neatly from the inside of the fence using the remaining pieces of profiled sheet or ordinary boards. Of course, this will spoil the aesthetic appearance of the fence, but thick bushes planted around the perimeter will easily solve this problem.

- If you want to plant flowers along the high base, then it is better to choose varieties that are not afraid of shadow

- To smooth the walls of the concrete foundation, it is recommended to add stone chips to it before pouring it.

- Some builders for additional stability weld jumpers to the posts. It is worth doing from the outside or between the pillars. This method requires a lot of time and effort, but will allow you to get a very tough and reliable frame. In addition, each individual support will be attached to the sheets and thereby strengthen the entire structure.

- The amplitude of the corrugated wave directly affects the stiffness of the professional sheet. Accordingly, the larger this value, the stronger the fence will be. If the site is located on terrain with strong winds, then the material of class c20 will be optimal.

- Choosing the thickness of the sheet, you need to consider the future height of the fence. For a fence up to 2.5 meters, a thickness of 0.5 millimeters will be optimal. A standard fence for the dacha is rarely done above two meters.

- Coverage should also be given special attention. Powder coating is more resistant, so you need to make a choice in his favor. It is worth considering the fact that the standard profiled sheet is sold with paint on one side only, the reverse side is either painted gray, or is not processed at all. If the appearance of the inner part of the fence is important for the owners and they have no desire to spend a lot of effort on the decor, then it is better to get a professional flooring with double-sided coating.

- If it became necessary to cut the profiled sheet by yourself, then special metal shears will help. In this case it is better not to use the grinder, because the edge can turn out with notches, and scissors are much safer.

- Another important feature, which for some reason many builders neglect, is that the top of the support column should be brewed, otherwise it will simply flatten out and this will lead to moisture getting inside and, as a consequence, to increase and cracking of the support in winter time.

- Installation of the pillars is better to start with the extreme, fixing them with wedges and a tensioned cord. Focusing on them, it will be much easier to adjust the height of the next pillars.

- It is necessary to start the fixing of profiled sheeting and lag only after the concrete has completely dried, and this will take 3-4 days.

- Sheet does not require special care, but you still need to ensure that rust does not appear and just clean the fence from contamination.

- An alternative and more budgetary variant of the foundation is the foundation on screw piles. It can be mounted in any weather, saves the cost of building materials and their transportation and its devicetakes much less time. In addition, deciding to establish a screw foundation, you do not need to worry about the indicators of the soil, because they in this case do not matter.

Beautiful examples

The classic example of brick pillars with laying one and a half bricks. The supports must be protected from above with metal caps. Such a fence requires a solid strip foundation with additional reinforcement.

The combined design with supports from a natural stone very beautifully looks. But to make such a fence, you need to spend a lot of time and effort.

Excellent design solution - drawing-imitation for wood. Looking at such a fence is not immediately possible to guess that it is made of corrugated

Forged items are able to give a luxurious look to even the simplest of the corrugated fence.

Properly selected garden furniture, lighting and decorative elements will be perfectly combined with the simplicity and style of the fence made of corrugated board.

Along the entire fence can be equipped with a frame, and the grooves in it to use as shelves. In this example, candles are placed on such shelves, which create a cozy courtyard lighting in the evening.

Simple wooden props look very stylish, if you choose the right professional sheet tone for them.

Another original solution is decorating with flowers cut from aluminum. Their production will require a lot of time, but it is a good opportunity to make your site recognizable and unique.

Simple flower pots attached directly to the fence will be an excellent design solution. This option is universal and does not require large expenditures. Pots can be made from improvised means.

Graffiti on a professional flooring is most often found on urban fences and is associated with vandalism. But having paid due attention to the design and quality of work, you can get an original fence in the street style.

The framework of the fence can be used as shelves. There are, of course, few places, but small candles will fit and create the desired effect.

Looking at such a fence, it is not immediately possible to guess that it is made of corrugated board. With the help of openwork forging and an additional gate, this fence was turned into a real work of art.

Such an extraordinary landscape can be painted with the necessary skills, or printed on self-adhesive film and simply mounted on the fence.It is worth remembering that the metal profile will last much longer, and the film will soon lose its appearance and begin to peel off.

In this example, many decor techniques are combined - each sheet of corrugated board is placed in a frame, the upper part of the fence is decorated with curly cutting. The whole composition is complemented by forged elements. It will take a long time to decorate such a fence, but such a chic look is worth it.

Another example of a well-painted fence. Drawn natural elements in the form of greenery very organically fit into the general appearance of the site.

With the help of shape cutting, the upper edge of the fence is made in the form of a kind of peak. It should be borne in mind that in this way you can decorate not every fence, but only with a certain type of corrugation.

One more option of registration of a professional leaf under wood. Such a six-meter fence will look organic on a plot with a wooden arbor.

The drawing on the material can create not only wood, but also stone - however, in this case, you need to take care that such a fence does not stand out too much against the background of a residential building.

On how to install a fence of corrugated, see the following video.