Fence posts: varieties and installation work

Massive solid fences are needed to hide privacy from prying eyes and the elements. Decorative models, on the contrary, are designed to maximize the view of beautiful buildings, to decorate them, only slightly demarcating the boundaries of certain possessions. In either case, they could not function without reliable supports in the form of various types of pillars and posts. Therefore, at the planning stage of the fence, it is important to determine which option is right for you and how practical it will be.

Special features

One of the important characteristics of the supports is ability to withstand heavy loads, which depends on the following nuances:

- Of great importance are the climatic, geological and geodesic parameters of the area: natural phenomena (wind, rain, seismic situation in the area), the processes occurring inside the soil (subsidence,resistance to freezing), the proximity of groundwater. Since a person cannot influence them, it is very difficult to change - it only remains to take them into account when choosing the material, shape, type of pillars and the place suitable for their placement.

- The weight of the attached structure should not exceed the maximum permissible. This indicator depends on the estimated distance between the pillars and the height of the future fencing.

- Much depends on location. When hanging a gate, wicket or door, special attention should be paid to the method of installation and the safety of the fixings.

Other important characteristics of supports for the fence are:

- Strength.

- Versatility. Compatibility with different materials sections.

- The possibility of using different fasteners (except welding).

- Ease of installation and ease of delivery (since the involvement of specialists entails additional costs).

- Long service life and no additional costs during it.

- Accessibility (for different segments of the population).

Kinds

All columns depending on the material can be divided into the following types.

Metallic

They are a pipe or profile.The package usually includes a headband, tips, plugs, straps for mounting. They differ in thickness (cross-sectional size) and shape (they can be round, square and rectangular). The thinnest ones (5 cm) are intended for fences from the chain-link mesh and other sheet materials. Racks with a greater thickness (up to 10 cm) can withstand the weight of forged sections.

Stone

Such supports can be made of artificial stone (bricks, cinder blocks, foam blocks) or natural (pebbles, sandstone, dolomite). Choosing natural stones, you should pay attention to their surface and strength. As a rule, a metal rod is placed inside for reliability.

Natural stones are laid out only on the outer layer.

Wood

Choosing bars or logs, pay attention to how well they are dried, because raw wood can stratify or mold, start to rot. Naturally, this option will not last for a long time, even if in good faith to look after him.

The strength is also affected by other defects, for example, branches and areas affected by insects.

Usually for the fence take such wood as oak, birch, larch, pine.

Reinforced concrete

As is already clear from their name, they are made of concrete reinforced with an iron profile.This type of support can be made independently by mixing concrete with sand or purchase ready-made (from a special high-strength and frost-resistant composition).

Concrete bollards can be monolithic or prefabricated (their parts are combined on site and can significantly save time for the construction of the fence).

Asbestos

The most affordable option pillars. Their variety are asbestos-cement. Available in the form of round hollow tubes with an inner diameter of 10 cm. The thickness of the material itself is 1 cm. It is necessary to purchase plugs to prevent water from getting inside.

Plastic

Often, plastic, since this material is not very strong, makes special pixel panels that are used for the outer layer of supports. They are mounted on the profile iron racks, while protecting them from the effects of natural forces and providing a presentable appearance.

Which is better?

Of course, each type of support has its advantages and disadvantages. The same plastic, with its convenience, versatility and ease of installation, although it creates an imitation of a brick pillar, but never with him the strength can not be compared.

Stone products have other advantages, for example:

- Durability.

- A huge amount of facing materials provides a pleasant appearance.

- During operation, they almost do not need repair.

- You can make them with your own hands, showing not only skill, but also creative qualities.

- Flexible pricing - with a shortage of funds, you can choose a cheaper type of stone or use artificial options.

For reliability and long service life, concrete products are similar to them. However, their heavy weight, to which a massive base must conform, makes their installation more costly.

Yes, and self-production in this case will take much longer.

Metal poles are not suitable for all variants of the fence. The density of the hung material should not exceed their own.

In addition, they need special treatment, as well as wood. Only proper protection will protect them from corrosion and rotting. Used products such as tubing (tubing) must be reprocessed.

Asbestos and cement poles are quite fragile and require careful installation.

But on the other hand, they do not need to be cared for, and they are made of water only stronger. Their price is more than democratic.

How to choose?

In addition to financial capabilities, assessment of their strength during installation and the characteristics of the material, the choice affects the state, type of soil and depth of wastewater and groundwater. The most favorable for the installation of supports - rocky soil. Due to its hardness, it provides stability and stability to any structure. The water inside the reservoir practically does not move, therefore, there are no such problematic processes as erosion, settling and swelling.

Sand does not retain water and practically does not freeze through.

Difficulties can arise only with the fact that such soil is crumbling and can sink under the weight of the fence. To prevent this from happening, a broad base is needed.

The most difficult situation arises when it comes to clayey soil, which contributes to the accumulation of water in it. So that she does not come into contact with the support, under her make a kind of pillow made of rubble. Air accumulates in it, so it does not freeze through and can in no way affect the pillar.

There is another pattern according to which heavy materials, such as reinforced concrete, cannot be used for loose soil, if it does not have a wide and dense foundation.All these subtleties need to be taken into account at the stage of the acquisition and preparation of a land plot, because not all ideas can be implemented.

Markup

Directly on the site in accordance with the layout it is necessary to mark how the future fence will be located.

- To do this, you need to have a cadastral plan in your hands and discuss in advance how the fence will run with the neighbors in order to solve all problematic issues before construction begins.

- All segments of the fence are divided into equal intervals. At the same time, it is necessary to build on the dimensions of the component parts for the sections, since not everywhere a standard is not possible. In any case, this distance should not exceed 2.5 m. This value is directly proportional to the height of the fence.

- All measurements must be accurate, and calculations should be double-checked. Firstly, it will save you from additional expenses, and, secondly, if you order transverse strips of a ready-made length, their parameter may not be enough. If you do all the construction work yourself, you need to take materials with a small margin in order to be able to fit the components to each other.

- At the corners and at the entrance at the gate, pegs are driven in, between which a fishing line or rope is pulled. Its position must be taken into account when digging or drilling pits and placing billets. If the distance between the pegs is large, you can use intermediate pegs, which indicate the location of future pillars.

Installation

Metal pillars have the most installation methods. The main ones are the following.

Screwing

For this mounting method, the post must have blades or threads. Sometimes used screw piles with a flange to which the upper part is attached. Pile supports are suitable for any type of soil, even with a high level of freezing, since irregularities contribute to the consolidation and at the same time the structure of the soil is disturbed to a lesser extent.

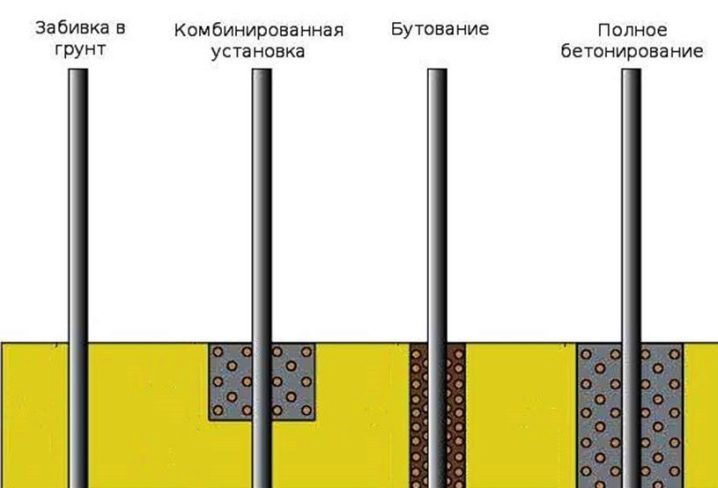

Zabivka

It is carried out by two methods - manually (you can score with a hammer or sledgehammer) and special devices. To dismantle such a support rack is easier.

Poking

During this process, crushed stone, gravel, sand, broken brick, and sand and gravel are poured into a wide hole. The first layer will serve as a support, so it, like all subsequent layers, should be carefully tamped.A pillar is placed on the bottom layer. As you fall asleep, you must ensure that it does not deviate from the vertical. You can alternate layers of rubble with sand or other materials. This method is also called dry concreting, since the top layer is covered with cement and poured with water. The thickness of each step is about 20 cm.

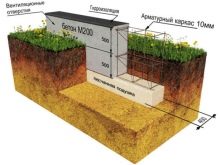

- Full concreting involves the initial sleeping of a layer of gravel, its tamping, formwork and pouring the rest of the space with concrete.

- The combined method includes several steps:

- Digging holes 2/3 of the estimated depth.

- The column is driven in such a way that its bottom edge is 30 cm below the pit.

- Backfilling rubble stone.

- Concreting the upper layer.

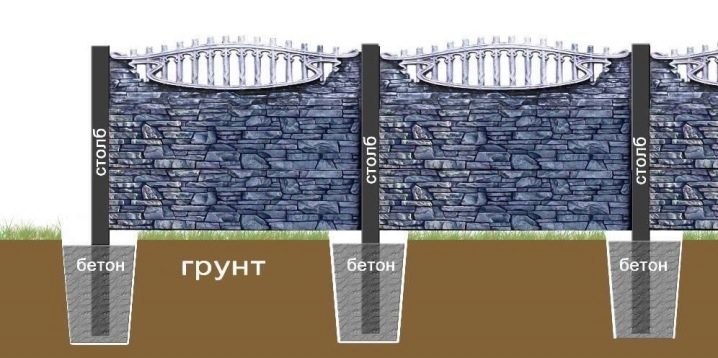

As a rule, a metal frame of rods or pipes is installed inside each stone pillar, therefore, holes are made for them in the foundation for the fence.

Reinforced concrete racks are installed:

- Concreting method.

- On a broad basis (a similar option provides a tape method of installation).

Asbestos columns are placed on the foundation, and also installed in a cementless manner (with the help of holders).All holes can be drilled by hand with a drill, with a special machine or with a shovel.

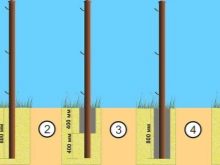

At what depth to bury?

Even at the design stage of the land plot, an estimate is made, in which the quantity of materials and their cost are prescribed. In accordance with the parameters of the fence, which are marked in the project and an order is formed for materials of a certain size, including support posts.

Their height is calculated by adding the following values:

- Heights fencing.

- Level of soil freezing.

- Gains for sustainability.

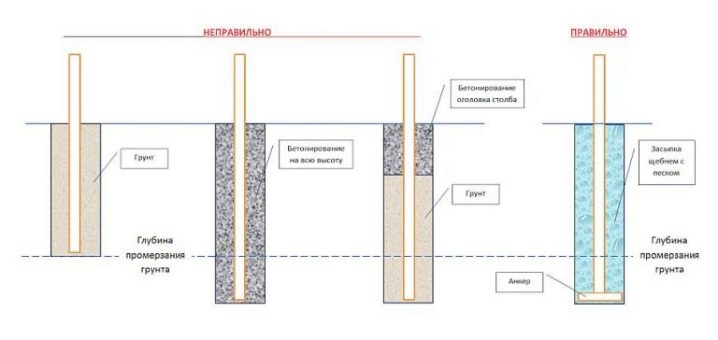

Why is the indicator of how much the soil freezes in winter? The answer lies in her ability to swell.

Ideally, the situation is when the groundwater is below the level of soil freezing and is not affected by any surface structures. If the water freezes through - they expand, creating pressure from below on all objects immersed in the soil. Such a pole risks being pushed out, leading to the destruction of the fence.

An additional increase of 20-30 cm is necessary in order to reduce the pressure on the substrate and reduce the associated risks.These figures, like other geodata, it is important to get at the planning stage. They are important not only for the installation of the fence, but also for the construction, placement of communications.

If this indicator is not available, you can simply observe the following proportions:

- The depth of the underground part must be at least one third of the total length of the pole. For example, if the height of the fence is 2 m, then the racks need to be deepened by at least a meter and the total length of the product will be 3 m. This value will help save money. Since metal pipes are produced with blanks up to 10 meters long, it will be more profitable to purchase it entirely and cut it into parts you need.

- Under the belt and a different type of foundation for the fence, a trench is being dug from 30 to 80 cm deep (depending on the weight of the fence and climatic conditions). The pressure in this case is compensated by an increase in the width of the base. However, sometimes deeper penetration is drilled directly under the pillars. Failure to comply with these conditions can lead to cracks in the base, pillars and sections, as well as their collapse.

Can I pour in the winter?

Most construction projects, especially if they are carried out independently (without experience in this area), are suspended with the onset of cold weather.This is connected not only with convenience, but also with the fact that low temperatures interfere with some building processes.

When pouring concrete, the time it takes for it to become hard increases. This is due to the slowing down of the process of evaporation of water.

You can speed up these conditions with the help of:

- The use of special formwork from heat-saving materials.

- Additions of salt and modifying additives.

- Heating solution.

- Acquisition of more expensive cement with improved performance.

We will make a reservation that all these works can be carried out in conditions of a slight cooling (according to some data up to 5 degrees below 0). If the object is located initially in a cold climate, such conditions, on the contrary, will be more favorable.

The advantages in this situation will be:

- Cost savings due to seasonal decline in prices for building materials and labor.

- If the soil contains a lot of sand, the installation of the fence will be even more convenient, because it will not crumble.

Among the drawbacks, in addition to an increase in the solidification period and the cost of equipment and additives, it can be noted that any failure to comply with the technology or a sudden drop in temperature will lead to the appearance of defects.

Treatment

In some types of pillars, it is possible to significantly increase the service life by processing with special means.

- Metal products in production are coated with polymers or zinc plated. Directly in place, their surface is treated with bitumen mastic. These precautions protect against the oxidation of a metal by the action of water or substances in the soil.

- The tree needs not only protection from moisture, but also from insects. For this purpose, impregnations are used, which contain pest-repelling substances.

- Concrete structures, asbestos-cement and plastic posts do not require special treatment.

In addition to practical qualities, the coating can seriously improve the appearance of the support. The decoration of the metal is painted with enamel on metal or varnish. Before applying the paint, it is mandatory to clean the surface of already existing traces of corrosion, degrease and apply a primer. Finishing with facing brick or false panels allows you to create pillars with imitation of different types of stone and other natural materials.

The decoration of solid wood, like any other natural material, is its texture, a special woody pattern of tree rings and fibers. Color can be emphasized with the help of stain or varnish.Due to the fact that they lend themselves well to processing, it is possible to carve or make quite unusual shapes.

Successful examples

In order for the fence to look beautiful, it is not necessary to resort to the services of designers. Having shown his creative potential and imagination, any person can create an idea of unusual design. Even a simple asbestos pole can look bright. To do this, it is only necessary to choose the paint and the original top.

In addition to the support function, the pillars can replace street lights. The main thing is to find a suitable niche for the lamp.

The traditional version of wood in a modern version with a 3D effect will become a local landmark. A feature of this kind of fencing is the creation of three-dimensional shapes based on a picket fence or interlacing of longitudinal and transverse rods of metal, plastic or solid.

A corrugated fence is able to hide the supports in the form of pipes - they will be visible only from the inside.

The block pillars will be noticeable in any case (due to their parameters), so you can focus on them by choosing a contrasting, in relation to other parts of the fence, paint and texture.Pillar blocks can be an unusual shape.

Recently, it has become fashionable to install eurofence. It is interconnected concrete pillars with grooves and sections. Facing spans can be in the form of an imitation stone, various ornaments, mosaics. Pillars in this version can be made in the same style or neutral colors to dilute the diversity of colors and reliefs.

To learn how to install a fence post on clay soil, see the next video.