Stair balusters made of wood: natural beauty and comfort

The staircase in any high-rise building not only connects the floors, it also makes the descent and ascent safe, and besides, is an important element of the interior, emphasizing its style and conceptuality.

Features and Purpose

Wooden balusters are low supports connecting the handrails with steps. Their main purpose is to ensure safe movement up and down the stairs, preventing falls and injuries.In addition, they have an attractive design, so they often perform a decorative function and serve as a real decoration of the room.

Thus, it is possible to designate the following functions performed by balusters:

- ensuring safe descent and ascent;

- support function;

- giving stability and rigidity to the stairs;

- interior decoration.

Balusters are mounted throughout the entire staircase mechanism, so the design becomes more rigid, stable and reliable.

Balusters are made from a variety of materials: metal, plastic, polycarbonate, and even glass, but for many decades, options for wood have always been in high demand. The explanation is very simple - the tree has the highest performance characteristics:

- Wooden balusters distinguished by complete environmental safety, they do not emit harmful and toxic substances.

- Aesthetic appearance. As for the form of balusters - here the restriction can only be the imagination of the owner of the dwelling, they can be carved and turned, the most valuable are the variants with hand carving.The use of wood allows you to turn the stairs into a real work of art, unlike all other materials. However, the price of such a masterpiece is quite high.

- Versatility. Wood railing can organically fit into any interior - they favorably emphasize the classics, form a single whole with country and Provence, and also stylishly set off modern.

- Ease of installation. Installation of wooden balusters does not require special skills and professional equipment, even a novice master with the most standard set of tools can do all the work.

- Wide selection. A wide range of wood types of different textures, shades and prices offered for sale allows everyone to choose a material for every taste and wallet in order to create from it precisely those balusters that suit him in style and budget.

- Wood is beautiful combined with other materials. Very stylish look railings made of wood and glass, as well as options that combine metal with expensive wood species.

- Balusters can be made at home. This will make it possible to achieve substantial savings and reduce the overall level of expenses for the arrangement of the stairs in the house.

- Durability and durability. High-quality products made of wood with proper care can serve faithfully for quite some time. The minimum period of use of such balusters is 50 years.

- The possibility of repair. In case of damage to individual structural elements, it is possible to replace only the damaged part, and not to dismantle the entire rail.

The lack of such a railing is only one - every few years it is necessary to process special coatings and fire retardants, which will increase its resistance to burning and resistance to external adverse factors.

Species

Balusters in their eyes can transform any, even the most boring ladder. Due to the abundance of options for shapes and sections, a wide variety of styles of design solutions is achieved.

There are several types of balusters:

- Round. This is the easiest option for support columns, which is columns in the form of cylinders with a cross-section of 3-5 cm. As a rule, they are made from a single piece of wood and often combined with metal structural elements.

- Square. Such racks perfectly emphasize brevity in the interior, so they are installed in rooms where simple strict lines prevail.To make balusters more interesting, curly carving can be applied on their sides.

- Flat. This option is most often made of plywood or boards, to achieve a decorative effect, they are decorated with all sorts of ornaments and carved patterns.

The last option is the easiest, so it is most often used if the stair structure is installed by hand. All that is needed for such works is a regular jigsaw, and, of course, the main material.

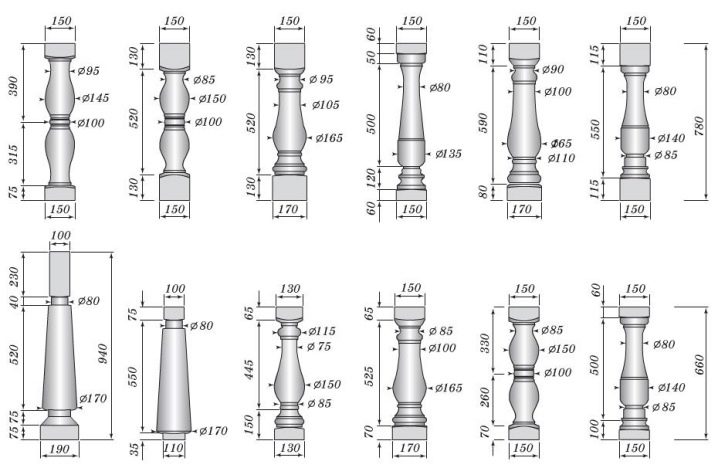

There are several basic techniques of making balusters. Depending on their product can be divided into several types:

- Turned. This is the most widely used wood treatment for creating supports. They are made on a lathe and purely visually look like shapes of bodies of revolution. A distinctive feature of this method is the simplicity and stylish design of the finished product.

- Milled For the manufacture of these racks used hand milling cutter, and as the blanks used turned balusters, which are decorated with all sorts of spiral, spiral and longitudinal notches.They have an attractive appearance and serve as an excellent element of decor in the interior.

- Carved. These are the most beautiful balusters that are manufactured on CNC process machines using the 3D modeling method. This allows you to create any form, even the most ornate. Making carved balusters is very laborious. These models can not be made by hand, so their cost is quite high.

Wood selection

For the production of balusters can be used a variety of wood species. Most often they take varieties such as oak, larch, beech, birch, ash and pine. Each of them is unique, distinguished by its own texture and pattern, as well as its distinctive performance characteristics.

From oak

This breed has the highest strength characteristics, but at the same time such wood is flexible, resilient and impact resistant. Oak constructions are considered the most durable and reliable, they can be used for up to 100 years! At the same time the texture of the tree is quite beautiful.

The tangential cut of the oak gives a pattern in which the pores are clearly visible, and when radially cut, the heart-shaped rays protrude.It will be right to use a bog oak, which is much stronger than usual, but it has a dark, almost black color, which significantly reduces its scope.

Oak, as a rule, is used for arranging wide staircases in large spacious houses.

If you decide to opt for oak, then you need to take into account several factors:

- to achieve the greatest expressiveness of the figure, structures from a large profile should be produced;

- In the work it is necessary to use the material aged from 80 to 150 years, because it has the greatest flexibility and plasticity and allows you to create figured decorative elements.

Larch

Larch is easily recognizable by its characteristic shade - it has a creamy brown color with traces of resinous drips. This is a very durable wood, but in processing it is rather heavy. Breed differs in high resinous content which creates additional pressure upon the tool during processing. Working with him requires perseverance and patience.

Larch has the strength and flexibility, so the balusters can be given any desired shape, while the material is resistant to adverse factors and resists infection with fungus and mold.

To significantly increase the life of balusters from this type of wood, it can be done by treating it with varnishes based on nitrocellulose, and it is very important to completely dry the product. Otherwise, the coating may crack.

From beechwood

Beech is a material with exceptionally high strength. Among all types of wood, this breed is the absolute leader in terms of this indicator, therefore, the railings from it are equipped in rooms with increased load on fences - in public places, schools and rooms with large concentrations of adults and children. Such wood has a long service life and retains its appearance and strength properties for several decades.

To enhance the aesthetic characteristics and protection from external adverse factors, it is varnished, and the varnish is absorbed in full and fairly quickly.

The only drawback of the material can be called its tendency to form growths. However, designers and this minus turned into a plus and began to use these seals everywhere to create an unusual pattern and topography of the coating.

Beech, as a rule, is used to make carved balusters.

Birch

Birch is one of the most popular options due to its hardness and affordability.

Distinctive features of birch wood are:

- high degree of strength and impact resistance;

- simplicity in processing - work with a birch does not require efforts, it can be done on the simplest equipment without special skills in woodworking;

- good flexibility, thanks to which you can create any form and reliefs;

- Unusual wood pattern due to chaotic fibers.

The most popular varieties of red-brown and black colors.

Tip: when choosing a material is to give preference to the tree harvested in the autumn. Such raw materials are more durable and durable.

From pine

Pine is the most accessible material because it is in the lower price category. It is optimal for the arrangement of stairs in a limited budget. The wood of this breed has a pleasant reddish tint, and the texture is very thin - it allows you to create quite interesting patterns. From the point of view of the physico-technical characteristics of the pine is durable and flexible, so it can serve for many years. This material responds well to processing.

The lack of pine is associated with its high resinous content, which makes it difficult to varnish balusters. The fact is that the resins are unevenly distributed in the structure of pine, therefore, areas are formed where their concentration is higher. If you use, for example, the stain, then in these areas it is absorbed better and deeper, and the color, respectively, will become more pronounced and darker. As a result of this treatment, the coating will be painted with “shreds”, which will significantly impair the appearance of the product. For processing pine optimal light or transparent varnishes.

From ash

This is wood of very high quality, which in its strength parameters is similar to oak. This material is used for structures with a long service life, since it is durable, strong and resistant to mechanical damage of medium strength. It is desirable to use such wood in its natural form, without treatment, since during lacquering it loses its noble color and unique texture. However, even without such a tree looks very aesthetically pleasing and stylish.

When deciding on the use of ash in the manufacture of balusters, you should keep in mind several features of this material:

- the material has high strength, therefore it is not suitable for creating small and intricate patterns;

- work with ash requires mandatory compliance with safety regulations;

- such balusters should be installed on stairs with three or more steps.

Regardless of which tree you decide to give preference to, you need to remember that wooden balusters are reliable and durable structures that provide plenty of opportunities for the realization of the most original design ideas and ideas.

Design

The most stylish and aesthetically attractive products are made on modern technological equipment - CNC machines that allow you to create any desired form of supports.

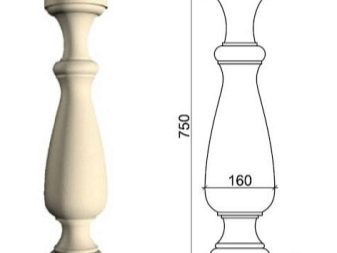

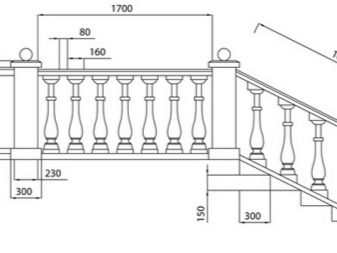

By itself, the process of making balusters is quite complicated, it requires woodworking tools, as well as perseverance and at least minimal skills in working with wood. Therefore, in order to make the railings as functional as possible, at the first stage of the arrangement of the staircase, it is necessary to design the future structure, make a drawing and calculate the required dimensions of the balusters.There are a lot of variants of sketches, but it is necessary to calculate the optimal height of balusters individually.

As a rule, their height is 90-120 cm, but to determine the required indicator more accurately, you can spend a little experience: when you descend from the stairs, extend your hand and measure the distance from your fingers to the tip of the foot - this height will be the most optimal and convenient for you . The width of the balusters depends only on the design ideas, and their frequency must meet all safety criteria. Thus, the maximum distance between the supports should be 15-20 cm, and if there are children in the family, then to reduce the risk of falling out, the step between them should be even longer.

It is very important to design a future form of balusters before starting work, and then make a drawing. At the next stage, the drawing is transferred to the workpieces and the manufacturing stage of the structural elements begins directly.

Manufacturing methods

To start making balusters, you need at least minimal experience with wood and a set of necessary tools. If the future baluster is smooth and round, then to begin with, the workpiece is made octagonal, and only after that it is rounded and proceeds to the final polishing.Carved balusters are considered to be a more sophisticated option, but their production is more labor-intensive: first, a sketch should be drawn up and transferred to the blank with the obligatory observance of all exact dimensions.

For the formation of unusual patterns for working with wooden blanks using a variety of incisors:

- reyer - used for milling round arches;

- Meisel - contributes to the creation of concave spherical elements;

- cutter jamb - used to create a cone-shaped structures.

Production of balusters directly occurs in accordance with the following work plan:

- Billets must be installed on the machine, with the fixation must be carried out strictly in the center, otherwise the final symmetry of the product will be broken.

- The edges of the bar are cut, for this they are turned around with a semicircular chisel.

- Further, in accordance with the drawing, the figured details of the baluster are machined. For this most often use incisors located at an angle of 45 degrees.

- At the finishing stage, grinding and polishing of the product and further decorative impregnation with varnishes are carried out.

The technology of making flat balusters is a bit different.For this you need a sheet of plywood, the necessary templates and a regular jigsaw. The sequence of works is as follows:

- creating a sketch using patterns of ornaments and slotted threads;

- full-size pattern is transferred to the workpiece and cut with a jigsaw;

- through elements of the pattern are drilled with a drill and then adjusted with a jigsaw tile;

- edges are polished with emery;

- flat baluster elements are glued to each other with special glue;

- after drying the blanks balusters are mounted on the railing, for this also use adhesive compositions.

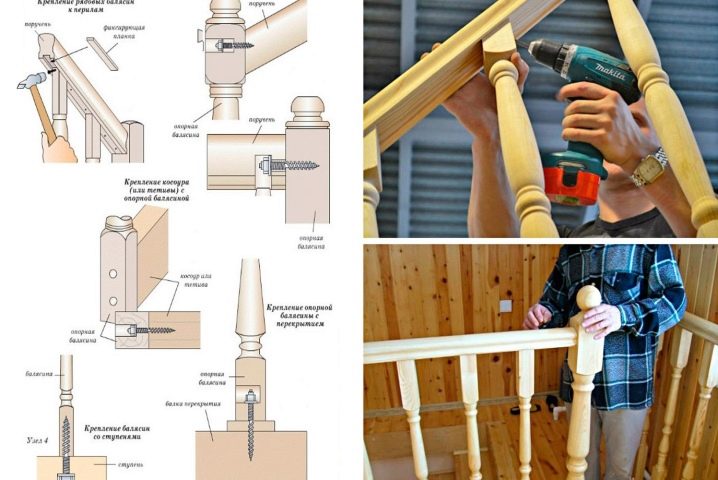

Mounting options

The cross supports can be fixed to the steps in three ways:

- using wooden dowels;

- self-tapping screws;

- threaded studs.

Regardless of the mounting used, the assembly takes place in the following order:

- To begin with, the angle of inclination of the structure is measured. This is of fundamental importance when placing supports under the railing.

- Next, a hole is drilled into which one of the fastener options is inserted.

- On the studs / shkaty / screws are mounted balusters, are set to the level and fixed, most often with glue.

Beautiful examples and options

Carved baluster pillars are considered the most stylish and expressive. Prices for such products vary greatly depending on the type of wood used and the method of applying the thread.

One of the most attractive options for carving is considered to be openwork. As a rule, it is used for drawing on flat materials and is most often used as decoration as overhead items. This thread is also called "wooden lace".

Blind carving is a flat wood processing method. Such elements are an adornment not only of the flight of stairs, but also of the entire interior as a whole. Only the most experienced masters take on such work.

The sculptural carving allows you to put any images you like - people, animals, plants. Such balusters often look like real sculptures.

On how to install balusters, you will learn in the next video.