Varieties and installation of facade cassettes

A variety of modern materials for finishing the facades of buildings is constantly updated with new products. New generation products for exterior cladding combined most of the positive qualities of existing materials, which led to their demand among consumers. These products include facade cassettes.

Features and specifications

Vented material for finishing is often called metal cassette. The main feature of these products is their design - they are made in the shape of a rectangle or square from different metals or alloys of raw materials. The edges of the cassettes are bent inward, due to which they have similarities with the box. Such a box has special holes for fastening, as well as a bend in the upper part of the product.The bottom edge is hooking; it contains openings for exiting the accumulated condensate and ventilating the base.

Installation of products to the wall is done with screws or rivets. In addition to the main purpose, facade cassettes are used in the arrangement of hinged structures for different purposes.

The material is included in the group of building products for lining, their use allows you to radically modify the exterior of the building. In addition, the products creates ventilated facades, improving the exterior and acting as a budget option when working on the reconstruction of buildings.

Products are sold complete with other components that are required for fastening.

The set includes the following elements:

- metal profile;

- slopes;

- wind panels;

- fastening crutches;

- platbands;

- products with the help of which gaps are hidden during installation;

- corners used for mounting.

Advantages and disadvantages

Cassette products are widely demanded.

This is explained by the presence of positive characteristics of products:

- durability of such facing;

- the strength of the elements due to the specificity of production and the type of raw materials used;

- quick installation - assembly of the facade from the cassettes is carried out in the shortest possible time, and for the work there is no need to hire a professional team of builders;

- products provide excellent protection of the base against negative atmospheric phenomena - strong wind, precipitation, ultraviolet;

- products are fire resistant and tolerates temperature fluctuations, including low temperature;

- the cassettes, as well as the linear panels for the facade, exert minimal strain on the walls of the building, since they have a low weight;

- in the space between the bases and the products, you can perform thermal insulation or lay an additional layer of waterproofing, which will increase the comfort in the rooms;

- the configuration of the material, due to their smooth surface, can visually hide all defects of the walls of the building;

- In addition, cassettes can also be used for interior work.

Each material has negative features, and front cassettes have disadvantages that are inherent in each individual product variety.

Steel products have more weight than other types of products.Therefore, the use of cassettes of steel will require the construction of a frame for mounting elements. When finishing such cassettes with structures that do not have a solid foundation, there is a risk that the building will collapse from additional load.

Aluminum front cassettes have two minuses - high cost, as well as time-consuming transportation and specific requirements for storage conditions. This is due to a certain softness of the raw material, due to which, as a result of careless handling, it is possible to damage the edges of the parts or make dents on the surface of the product. The presence of defects will adversely affect the subsequent installation of such cassettes.

Composite products have low resistance to UV and heat. Therefore, before purchasing this type of product, you should familiarize yourself with the recommendations of specialists regarding the temperature that they can tolerate without compromising the quality and aesthetics of the house.

Production and device panel

Cassettes are manufactured exclusively in industrial environments. Only a few Russian companies are engaged in the manufacture of such products according to GOST.In the workshop, the production process is carried out using high technologies on the principle of a closed cycle.

In essence, the work itself on the creation of products consists in stamping a sheet of metal having a thickness of from 0.5 to 1.5 mm. For the production of used cutting and bending equipment. As a result, finished boxed items are formed. Quality control products pass at every stage of the process.

First of all, starting to manufacture, the shapes and dimensions of the elements are determined. Dimensional accuracy is a very important nuance in production, since all the components constitute a complete structure with a large area, where every detail must ideally fit the installed side by side. Therefore, production facilities are fully computerized.

The cut material is sent to the next manufacturing stage. - in uglovysechnoy machine that performs tasks on the design of the corners and contours of cassettes. After performing these works by bending, the blanks are finalized. Products that came off the conveyor are fully ready for installation; no additional processing is required for the elements.

Incas metal cassettes are Russian products of this line of building materials.In addition, composite and aluminum products of Alucobond and Puzzleton trademarks can be distinguished. The latter are made in various forms of shapes, including angular, triangular and trapezoidal products.

Kinds

Based on the raw materials used for the production of cassettes, the products are steel, aluminum and composite.

Steel

Galvanized steel is used as a material of production, which gives the products hardness and strength. In addition, the elements are impressive weight. The color range of steel cassettes is quite diverse, so you should choose products based on your personal taste preferences. This advantage is due to the specifics of the production of the material, which involves coating a galvanized product with a polymer film having a wide color palette.

Aluminum

Aluminum cassettes have an acceptable weight, which does not affect the strength of the products. The products differ in their impressive dimensions - the cassettes are quite voluminous, due to which the installation time of the products on the base of the building is reduced. The disadvantage of aluminum cassettes for facade cladding is their high cost incompared with other types of this production. But high quality pays for the cost of buying such a product.

Composite

The weak point of such cassettes is their low strength, in comparison, for example, with aluminum counterparts. However, the weight of the alloy cassette is small. Most often facade composite cassettes are used to design low structures where the walls and the foundation of the building are not designed for heavy loads. It is worth paying special attention that the assortment of cassettes can be represented by products made from alloys that have a low level of resistance to temperature fluctuations.

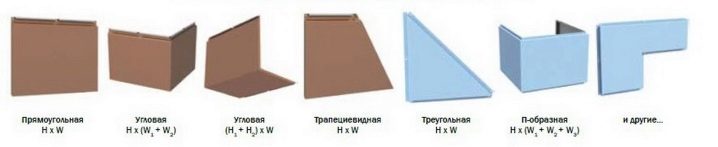

Forms and sizes

The operational dimensions of the cassettes can be different, the selection of suitable products should be carried out on the basis of the style and finish of the facade, and also taking into account the technological need. As a rule, the products have the following dimensions: the depth of products ranges from 20 to 55 mm, the width of horizontal and vertical joints varies between 5-55 mm. The height of the products can be 340-600 mm, width - 150-4000 mm.

As for the shape of the cassettes, the individual elements are mostly rectangular in shape, although long strips-panels with different widths are popular.

Finishing methods and stages of work

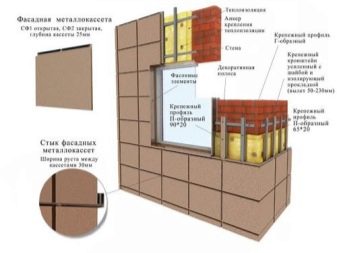

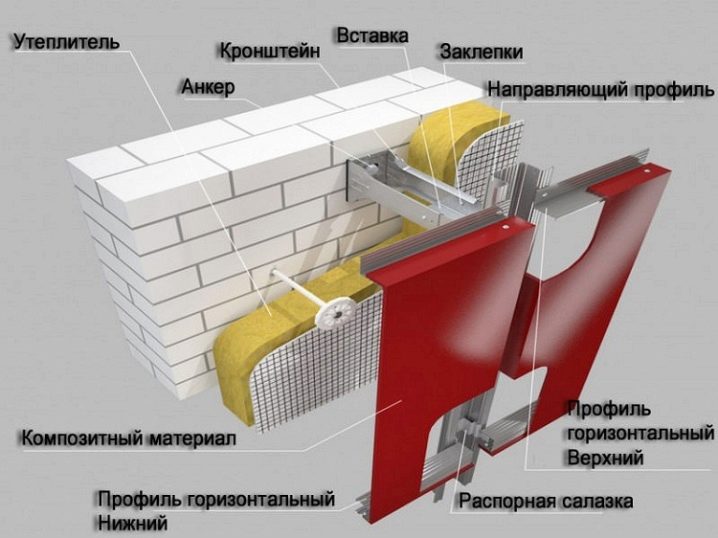

Each ventilated facade, the construction of which occurs when using cassettes of any kind, is a complete system.

Its structure contains the following details:

- metal profiles;

- corners, they act as a keeper;

- windproof panel;

- fasteners;

- slopes with platbands and flat bars.

Regardless of the complexity of the building structure, which is planned to be lined with facade cassettes, the presence of the above components will allow you to do the work in the shortest possible time.

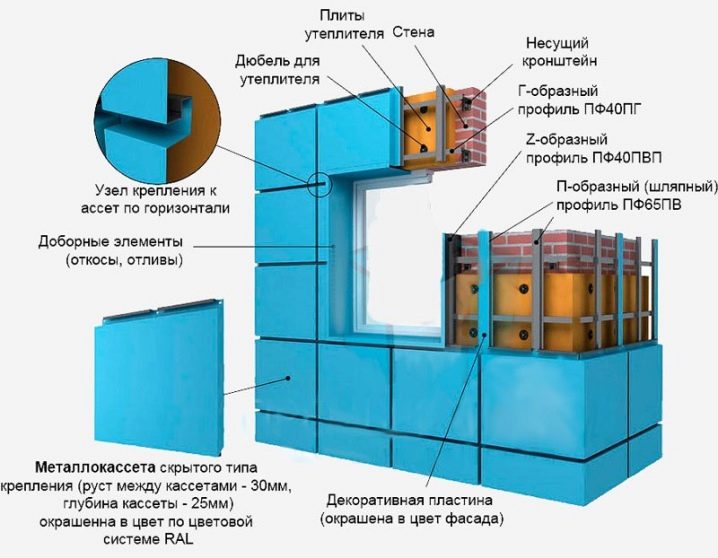

Installation of products can be done in two ways:

- hidden fasteners;

- visible fasteners.

The decision on the choice of one or another variant of mounting the cassettes should be based on the peculiarities of the building and its geometry.

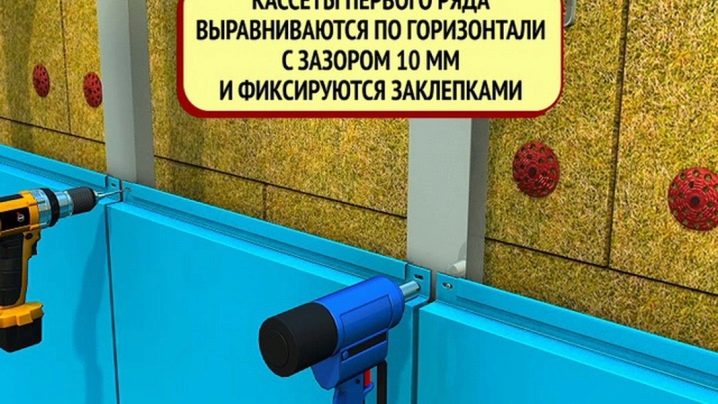

Experts consider the visible installation as the simplest technique for the performance of work. The configuration of each individual element includes a kind of bent edge with a special hole. Screws are screwed into it, fixing the product on the profile. This technique allows, if necessary, to replace the worn-out part, without dismantling the entire structure.It is the folds of the cassette that are responsible for fixing the entire part. For work to use any equipment is not necessary.

Hidden fasteners on their technology a little more complicated than the above option. But due to the use of this method, on the facade of the building a flat surface is formed from the cassettes, where the connecting seams between the elements and the parts used for mounting and fixing are not visible. Based on the mounting option, the front panel may differ slightly in its configuration, namely, the part will contain only one bent side. There is an edge on this part of the cassette. Its task is to fix the upper and lower elements with each other.

Facing the walls of the building with facade cassettes includes the following steps:

- First of all, the sheathing of the profile is installed on the base of the house. It has a cellular type. If you perform competent calculations of the height of the profiles, you can provide a good ventilation space between the wall and the facing material.

- If necessary, between the crate is insulating material.Most builders recommend the use of mineral wool for these purposes, since it has a dense top texture and a porous inner layer. In addition, in the course of work on the exterior of the facade of the house, you need to take care of high-quality wind protection. To do this, lay another additional layer of insulating material. The membrane fabric performs this function. That she can keep warm for a long time and protect the lower layer of material from moisture. All materials are attached to the crate with dowels.

- After the above actions, proceed with the installation of waterproofing for the building.

- The final step will be the installation of a special frame on which the fastening of the front cassettes will be carried out.

Useful recommendations

In order to properly perform the lining of the building, you should avoid common mistakes in the use of this material. For example, cutting during the work with an abrasive or gas-flame tool is strictly prohibited. Even before the purchase of materials should check the shelf life of products and the date of its manufacture.A material with a polymer coating on the base with all components, which is in the original packaging, can be stored no more than forty-five days from the date of shipment from production.

When buying material for public buildings, you need to know that additional installation on cladding from tapes of various signs is not allowed. For private households, the ban on installation to facade cassettes applies to the attachment of mounted visors, antennas, etc. Only components of the drainage system can be safely attached to cassettes, which should be fixed to the supporting base not connected with the facade cladding.

Purchased products require special storage conditions. - prior to the installation of the product must be kept in the packaging film, avoiding direct sunlight. Contact with ultraviolet light may cause changes in the composition of the adhesive, which makes it difficult to remove the film from the elements.

Care must be taken to protect products from moisture that will drain from the roof, for this gutter and drains must be in good condition.

Beautiful examples

Since the color gamut of the material is quite diverse, it is possible to select such a building from the total mass of structures without much difficulty. Using a contrasting alternation of colors during installation, for example, light and dark shades, outlining the correct geometry of the building, the structure is easy to see from afar. And the bright red details, highlighted in the general design, in combination with the cold gray color, will give the appearance of originality and attractiveness, guaranteed to interest such a bold decoration of passers-by.

How to mount front cartridges, see the following video.