Clinker panels for the facade: technical characteristics and installation details

The clinker panels are a popular type of decorative facade finish. The material was developed and put into production by specialists from Germany more than 40 years ago, and since then it occupies a worthy place in the market of building and finishing materials.

Specifications

The manufacturing technology of clinker is known for a very long time and consists in the extrusive treatment of shale clay, after which the products acquire high performance, and surpass clay and concrete materials in terms of strength and frost resistance. Such facing can often be seen on the facades of residential buildings and architectural monuments.

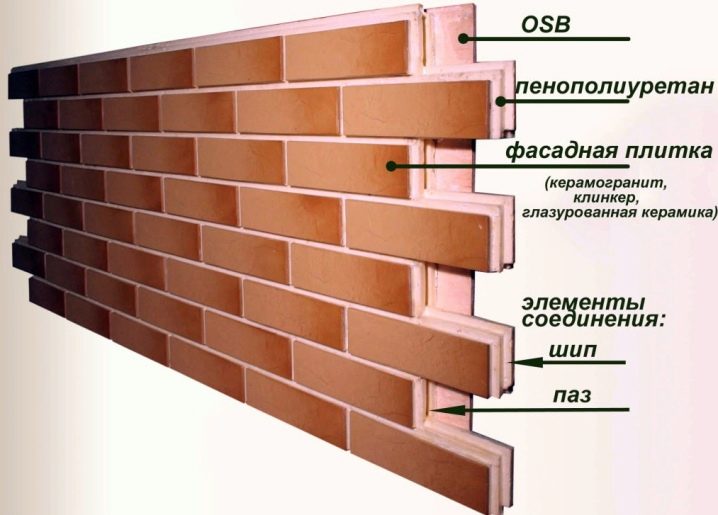

The clinker panel is a multilayer module consisting of a polyurethane foam sheet. from 2 to 8 cm thick on which the ceramic decorative layer is fixed.Thus, the clinker panel is a unique finishing material that harmoniously combines decorative properties with a powerful insulating effect. The manufacturing techniques of a tile which consists in the premise of ceramic preparations in special forms with the subsequent pouring by polyurethane foam structure completely excludes stratification of the panel in use.

The size of the plate depends on its design and purpose, and averages 1090х359 mm. The cost also varies depending on the size, number of layers and the manufacturer. The most expensive are the German models. Their price reaches 12 thousand rubles per square meter. Italian companies offer products at 7 thousand rubles, and Polish manufacturers produce more budget collections, which cost an average of 5 thousand rubles. The most budget option are considered domestic products. So a square meter of the panel, which is based on extruded polystyrene foam, can be purchased in just one and a half thousand rubles, polyurethane models will cost two and a half thousand, and panels that do not have heat insulation are sold at 1900 rubles.

Advantages and disadvantages

High consumer demand and a large number of positive reviews are due to a number of indisputable advantages of this material.

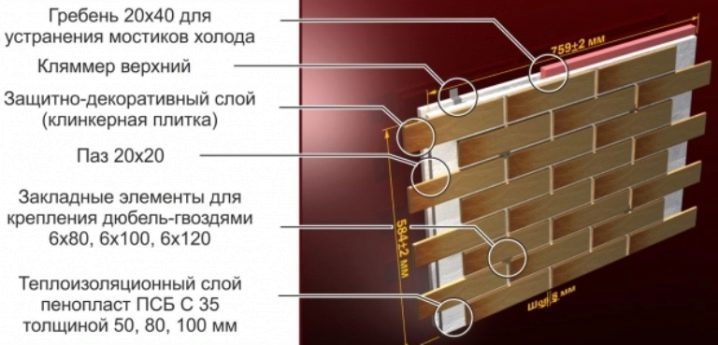

- The design of the panels allows facing of the facade in a seamless way. This favorably affects the increase in heat saving and makes it possible to significantly save on the heating of housing. The thermal conductivity of a clinker plate with an insulating layer of 8 cm thick is equal to the thermal conductivity of brickwork 70 cm wide or a wall of aerated concrete 40 cm thick.

- Monolithic panels have an attractive appearance and eliminate the need for plastering facades. The material is produced in a wide range with a wide variety of colors and textures, which greatly facilitates the selection and provides ample opportunities for the implementation of bold design solutions. The clinker layer is made in the form of a brickwork or stone, and can have both smooth and rough texture. The relief surface looks most impressive: it further enhances the visual similarity of the clinker panel with natural material.

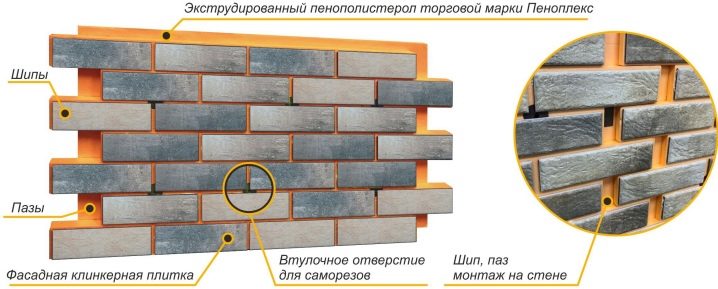

- Easy installation and easy maintenance.Thanks to the universal fastening system "thorn-groove", cladding the facade does not require the use of expensive tools and the involvement of specialists.

- The panels are highly resistant to ultraviolet rays, and therefore do not lose their original appearance for a long time, and do not require measures for their restoration and repair.

- Materials are not of interest to insects and rodents, and are not susceptible to the appearance of mold and fungus.

- The presence on the reverse side of the double-layer panels of special gaps, provides the necessary ventilation of the facade, which eliminates the need to install additional ventilation equipment.

- The tight connection of the panels between them guarantees the absence of cold bridges, the presence of which can lead to condensate accumulation and over-wetting of the facade.

- High sound insulation properties of the material will reliably protect the home from extraneous noise.

- The increased resistance to the effects of aggressive external environmental influences allows the panels to be operated in any climatic zone.The material tolerates temperature drops, is not afraid of excessive moisture and can last more than 50 years.

- The panels are lightweight, so the clinker cladding does not have a significant effect on the foundation and load-bearing walls.

- Possibility of installation in any season. The only limitation is the application of inter-smooth grouting. Its installation can be carried out only at a positive temperature.

- The presence of additional elements for the design of exterior and interior corners, windows and openings greatly facilitates installation and gives the building a finished look.

The disadvantages of the material include its high cost, which is especially noticeable when facing buildings in two floors and above. The downside is the fragility of the clinker layer. Ceramic coating does not withstand mechanical impact and strong shocks, has low fracture strength and requires particularly careful storage, installation and transportation. There is also a poor vapor permeability of the panels, which, if the installation rules are not followed, may lead to excessive wetting of the facade due to the formation of condensate.

Species

The clinker panels are available in two-and three-layered versions. The three-layer models consist of a ceramic layer, expanded polystyrene and an additional heat-insulating base, with which they are mounted on the facade. The additional layer can be made of fiber cement, glass-magnetism or oriented strand board. Fiber cement is characterized by environmental safety, good strength and durability. The glass-magnetism base attracts with flexibility and allows the facing of curved walls, and the plate on a wooden base has high noise and thermal insulation properties, is distinguished by low weight and low price.

In each plate, regardless of the number of layers, there are special holes and mounting grooves. In the process of production of three-layer models based on polystyrene foam technology is used, which provides a closed perforation, which provides finished products with minimal steam exchange. However, it should be borne in mind that the available vapor permeability indicators are not sufficient for adequate ventilation, therefore, clinker panels are not recommended for use on the facades of wooden houses.

The two-layer models consist of a clinker decorative layer and the base, made of OSB or DSP, and are intended for cladding facades that do not require insulation, or for those buildings where insulation has already been installed. Their main advantage with respect to the three-layer plates, is a good vapor permeability, which is due to the lack of insulating layer. Due to this quality, the walls of the facade have the ability to breathe, and the excess moisture is freely discharged outside. The service life of lightweight panels is 25 years. According to the location of the panel are divided into thinner wall, and thick basement options. The height of the ceramic layer of the latter can reach 1.7 cm.

Subtleties of installation

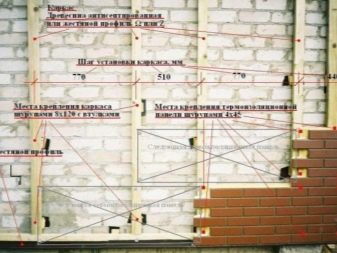

The cladding of the walls of the building with clinker panels should begin with the preparation of the wall surface. To do this, it is necessary to remove all protruding elements, in the form of air conditioners and shutters, remove the previous facing coating and treat the surface with an antiseptic and a primer. Then, you should proceed to the installation of the batten, which is necessary when installing a ventilated curtain wall and with large wall irregularities.The frame can be constructed from wooden bars or aluminum profiles. Planks made of wood should be pre-treated with special compounds that prevent rotting.

Fastening the guides should be carried out using self-tapping screws, the use of brackets is not recommended. Initially, the lower horizontal rail is installed, which should be placed at a distance of 20 to 40 cm from the ground and check its location with the help of a building level. Each panel should be located on three vertical bars, so when calculating the step between the slats, its dimensions must be taken into account. The gap between the bars and the wall is eliminated with mounting foam. After the installation of the batten is completed, you can proceed to facing the facade panels.

Installation of three-layer panels should start from the corner from the bottom, moving from left to right. To do this, on the first rail from the ground, you need to install the panel and fix it with dowels. Further installation is carried out on self-tapping screws and made round. You can proceed to the installation of each next row only in the case when the installation of the previous one has already been completed.For each laid row should fill the foam. This will increase the rigidity of the structure and provide a more tight connection between the rows. The finishing of slopes is made synchronously with the main facing. After the installation is completed, the interpanel seams should be coated with frost-resistant putty.

Lighter two-layer models without insulation are fixed on the wall or frame using adhesive composition derived from dry building mixture or glue-foam. This type of installation has restrictions on air temperature, which is regulated by the manufacturer of the adhesive used. Usually this indicator corresponds to -10 degrees.

Clinker facade panels are a versatile option for finishing buildings. Combining excellent decorative qualities and high heat-saving characteristics, they allow you to stylishly and effectively decorate the facade and make the house warm and cozy.

Detailed review of the clinker tiles and panels - in the video below.