Metal front panels: types and their characteristics

The construction market is filled with a variety of different materials used for cladding facades of various buildings and structures. This is a classic plaster, and brick or stone, and a special facade tile, but the most common version of steel panels for the facade. Such designs are often called "siding".

Features and benefits

The most widely used facade panels received during the construction of commercial real estate: various office buildings, business centers and retail and warehouse sites.However, more and more often, such facing panels are used in the decoration of the facade of private residential buildings and even high-rises.

Such a building material consists of two metal sheets, between which there is a mineral filler. From above, the metal is covered with a protective coating, which allows it to retain its original appearance and characteristics longer.

The filler and the type of fusion of the metal used may vary depending on the manufacturer.

The advantages of these metal structures include the following:

- low weight with increased strength and durability, which minimizes the load on the foundation of the house;

- easy installation and maintenance;

- the material is not subject to burning, and therefore safer than plastic or wood;

- resistance to aggressive media and mechanical damage.

With all its positive qualities, such wall panels still have two significant drawbacks:

- the need to purchase a large number of different fractional elements and special equipment for cutting on metal;

- the need to additionally insulate the wall surface before mounting the structure.

Such lining is used both for covering new and for reconstruction of old buildings, which makes it possible to give them a modern, attractive look. Thanks to the panels, the insulation is improved, as they create a kind of acoustic buffer. With the help of this material, you can level the facade and make it more ventilated.

Kinds

Metal panels have an average thickness of 0.55 mm. They are water resistant and fireproof. The degree of impact resistance is 50 kg / cm, and the flexural strength is 118 MPa. The classification of panels is based either on their appearance or on the metal used. Depending on the appearance of the panel can imitate wood, stone or brickwork. Profiles can be corrugated, smooth, perforated or different embossed on the edge.

For the production of facade panels can be used various types of metals and various ways of their processing.

Galvanized steel

Metal tile manufacturing enterprises also produce galvanized steel panels coated with polyester. Smooth, grooved or patterned - they all have a lock connection and are easy to install.The thickness of galvanized metal is 0.5–0.7 mm, and the coating not only protects the material, but also allows you to give the product a variety of colors and textures. Such material is the most versatile and is used when facing any facades, ranging from country and country houses and ending with trade pavilions and sports centers. The length of such panels can reach 5-6 meters and is ordered at the factory. You can mount them both horizontally and vertically. The panels are lightweight, durable and economical.

Unfortunately, because of its lightness, such structures are subject to deformation, as well as accumulate static electricity and require additional thermal insulation.

Stainless steel

Stainless steel is another popular facade cladding material. Covered with a layer of oxide "stainless steel" does not require additional coating with various protective agents. With the right grade, such steel panels are durable, have low weight and are very easy to clean, despite their rather big price. Like galvanized steel cladding, stainless steel requires thermal insulation and accumulates static electricity, but it is more resistant to corrosion.

Aluminum

Aluminum panels are also called composite.Their total thickness does not exceed 6 mm, and the length is 6 m. From above, the metal can be covered with an oxide film, which will protect the material and give it different shades. With this film you can get a mirror effect, imitate a wooden or stone surface.

A separate type of isolated composite multilayer panels of aluminum, called "Alucobond." Between the sheets of durable metal is either a synthetic polymer or polyethylene foamed under high pressure. Such material reliably protects the facade from moisture and mechanical damage, and also allows you to bring to life almost any design idea due to the fact that it bends easily and takes on the necessary shape.

Unlike galvanized and stainless steel, aluminum does not accumulate static electricity and does not require the installation of thermal insulation. However, it is a more expensive and less durable facing material.

Other types of metals

In addition to steel and aluminum, metal plates can also be made from other materials and alloys: brass, copper, and even bronze. Such panels are covered with glossy or matte varnish and installed using concealed fasteners.Inside, such constructions are plastered with sound-absorbing material in order to eliminate ringing during mechanical stress. They are durable, easy to install and dismantle. Such panels are used not only for cladding facades, but also for interior decoration.

Polymer coated

The basis of such panels is aluminum or galvanized steel, on which a protective coating of polymers is applied on top. The thickness of such metal panels is about 0.56 mm. They are smooth, corrugated or perforated. Such panels are moisture and frost-resistant, have good noise insulation, and also they are easy to install. Before installation, it is necessary to pre-heat the facade or use a more expensive sandwich panel. In order for such a lining to serve for a long time, it is necessary to correctly mount the sheathing from wood or aluminum profiles.

Metal-ceramic

Such panels are steel sheets that are covered with vitreous enamel. Enamel gives high resistance to aggressive environments, high rigidity and durability. Such structures are most often used in the construction of transport infrastructure: various tunnels, junctions and stations.However, today this material is increasingly used for cladding facades of ordinary residential buildings. Their thickness is 200 mm, the material is non-flammable, can withstand temperature drops from -60 degrees to +800. Products made from this material are easy to maintain and serve for over 50 years.

Design

In addition to the differences in the material from which the facade panels are made, they can vary in surface relief.

- Smooth. Conventional steel panels, which differ only in color. They can repeat a woody drawing, make up one big picture from fragments or be covered with gloss, creating a mirror effect.

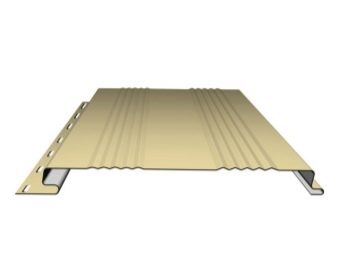

- Corrugated. Curved soft wave or hard angular protrusions.

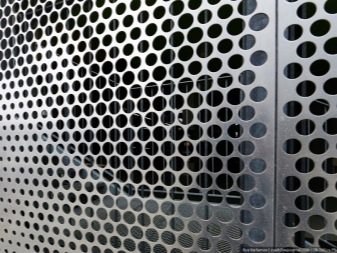

- Perforated. There are various patterns: from geometric to individual custom-made ornaments. In the dark, such panels let out the light emanating from the building and create a bizarre picture, embodying all sorts of ideas from designers.

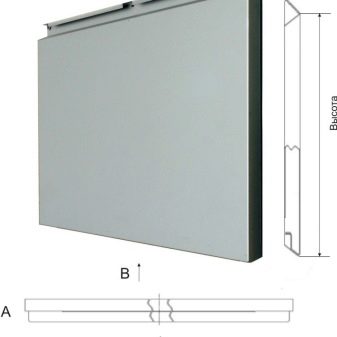

- With additional decorative ribs. Depending on the distance between these ribs, you can visually expand the facade or make it higher.

When finishing industrial and public places use, as a rule, cassette panels.

Such panels are of several types.

- Cassette - the volume panels consisting of an aluminum sheet or steel with a polymeric dusting. Such a cassette has a bend around the edges and is made not only in factories, but also directly on construction sites due to the simplicity of the design. Most often have a square shape and a smooth surface.

- Linear - elongated panels for exterior and interior decoration. Due to this design, the facade is mounted with a minimum number of gaps at the joints or without any gaps. Linear designs are similar to long cassettes, but may have a perforated or 3D surface.

With all the variety of materials, most of the facades are faced with sandwich panels made of several layers of different materials. The simplest products have three layers: two facing (metal, wood board or other materials) and one layer of filler (most often it is heat insulation).

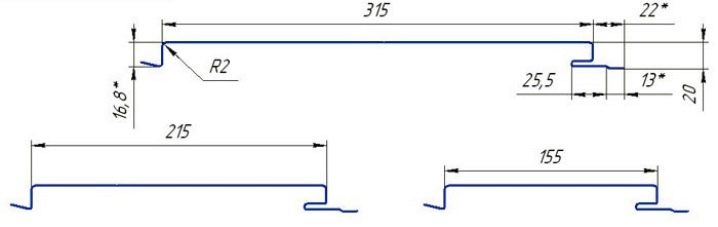

Dimensions and other specifications

The average dimensions of the steel facade panels are as follows:

- metal thickness ranges from 0.48 mm to 0.65 mm;

- the length of the longest panels (linear) can reach up to 6 m, but on average the length of the panels ranges from 2 to 3 m;

- the width usually ranges from 200–250 mm, but you can order siding of individual sizes - up to 300 mm (however, the large width of the product will increase the risk of deformation during transportation and installation);

- the weight of one square meter of such facing weighs on average from 2 to 3.5 kg.

Since the panels are sold individually, it is necessary to clearly understand how much material is needed for the work.

All calculations are always rounded up, and for beginners it is better to purchase several additional panels in case the first attempts fail.

Manufacturers Overview

The production of metal panels can be both manual (directly at the facility) and professional (at large plants). Products from foreign suppliers are represented by various companies, among which there are several brands that have received the best reviews: Finnish metal plates of the brand Ruukki (on the construction market for over 50 years), American siding from the company Alcoamade predominantly of aluminum, as well as the British-Dutch brand Corus group.

Among domestic manufacturers can be designated facade panels brand Grand line. Production of the Lipetsk section of the bending equipment and the INSI holding is widely represented on the market. As well as positive feedback from customers received products of the plant. SeverStal. The main difference between Russian manufacturers is that with the same quality, domestic products have a lower price than foreign ones. This difference is due to the absence of transportation costs.

Installation Recommendations

In order to veneer the facade of any building, it is necessary to consistently carry out the following stages of work.

Preparatory work

This stage includes cleaning the entire outer surface of the building from debris and old coatings, dismantling all foreign objects (shutters, gutters, antennas). In addition, it is necessary to remove any defects on the walls, remove all chips and irregularities in the concrete, process wood from rotting.

Markup

Using a perforator, special holes are drilled in places marked with markings.The markup is better to do bright indelible material so that in case of changing weather conditions do not have to start this again.

Crate

At this stage, the construction of the frame of wooden slats or metal profiles. Insulation is chosen so as to be no thicker than the crate, and fit snugly in the resulting "honeycomb." Insulating material is placed from the bottom up to the finished crate or directly glued to the surface of the wall.

It is important to use only dry insulation, since the moisture accumulated under the mounted panel can destroy it.

On top of the layer of insulation is covered with a waterproofing film, which prevents water from entering the already installed panels.

Installation

Most often, the process begins with the attachment of fractional elements: starting, angular and final strips. Then the wall sections next to the window and door openings are faced. In the case of the use of the finishing bar such elements are set, on the contrary, in the last place.

After installing the fractional, you can proceed to the installation of the remaining slats, starting from the lower left part of the wall. The elements are attached to each other with screws or special built-in locks, and you can also strengthen the existing lock fastening with additional screws. After facing is finished, all removed elements are returned to the place: slopes, drains, shutters, and so on.

In general, all the finishing work on the facade, in which metal panels are used, is carried out according to one simple algorithm - you can not be afraid to spoil and deform durable material.

Panels - a fairly economical solution for a private or holiday home, and the result will be pleasing to the eye for many years.

For more details on how to mount the panel system, see the following video.