How to fix PVC panels to the wall?

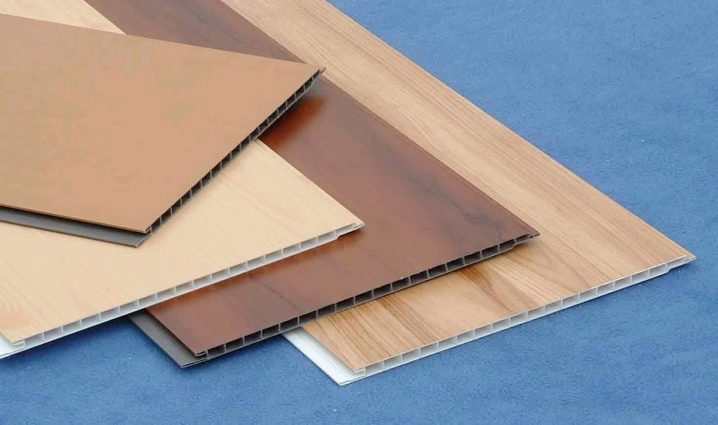

PVC panels are a popular finishing material that is durable, practical and affordable. Such coatings can be used for wall cladding, and for decorating the ceiling. Installing plastic panels is quite simple and fast. With such work it is quite possible to cope on their own. Today we will talk more about how to fix PVC panels to the walls.

Advantages and disadvantages

Plastic panels are popular and common wall covering. They can be found in many stores specializing in the sale of finishing materials.

Wide sheets and lining of plastic are in great demand, because they have many positive qualities.

- First of all, the durability of such finishing materials should be noted. In our climate, their lifespan can be more than 20 years.

- Such materials are durable. They are not afraid of moisture and moisture. In addition, they are not subject to rotting, such as natural wood.

- Plastic panels do not require complex and regular maintenance. Dust and dirt do not accumulate on their surface. If the finish is soiled, it will be cleaned with a normal damp cloth.

- PVC panels have noise insulation properties, so they are great for wall cladding.

- Using plastic panels, it is possible to divide the space into functional zones.

- Plastic panels are lightweight materials, making them easy to work with. All processes can be managed without the involvement of assistants.

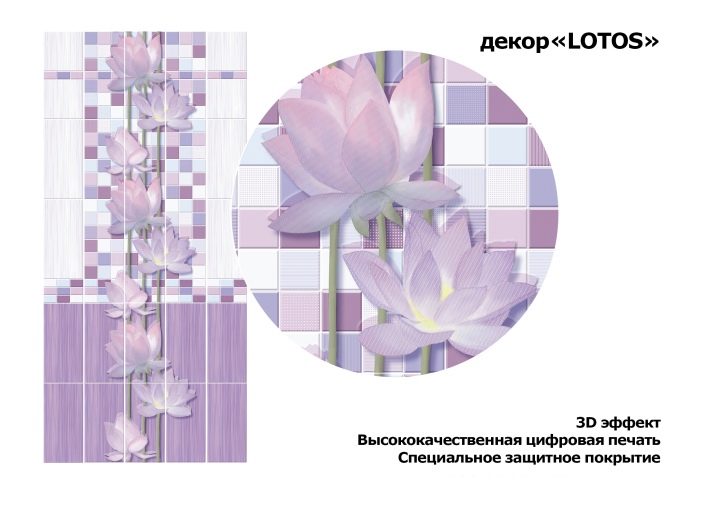

- Plastic is a very flexible material - it gives way to various types of processing without any problems. Therefore, in the shops you can find PVC panels having a variety of colors, textures, prints and ornaments.

- These finishing materials can be used in interiors of the most different styles.The only exception can be only fanciful and pompous ensembles, which must contain extremely expensive and natural elements.

- It is possible to install plastic cloths both in the city apartment, and in the private house.

- Behind the panels, you can hide various communications, such as wiring.

- Installation of PVC panels on the walls is quite possible to do it yourself, because this process is not complicated and inaccessible. You do not need to stock up on expensive tools.

Of course, PVC wall panels are not ideal finishing materials. They have their own weaknesses.

Consider them in more detail.

- PVC panels are flammable. In fire conditions, these materials burn strongly enough, spreading suffocating smoke indoors.

- Many consumers note that after installing plastic panels in the room, an unpleasant chemical smell persists for a long time, which is not possible to get rid of which by ordinary ventilation. Of course, in this case, much depends on the quality of the purchased plastic.

- PVC panels can not be called "breathing" finishing materials.They do not allow air to move through the ceiling, and this is very important for adequate ventilation in the room.

- Plastic panels have voids in which various insects and parasites often infest.

- PVC sheets are fragile. With a strong blow, they break. It is unlikely that we will be able to get rid of such deformations - the material will have to be changed.

Knowing all the advantages and disadvantages of PVC panels, it will be easier to work with them. You can avoid many mistakes in the process of installation.

Criterias of choice

PVC sheets produced by various manufacturers have different properties and performance characteristics. When buying a suitable material, you need to pay attention to its quality - this is the main criterion on which to rely.

Experts do not recommend to buy plastic panels.

- there are damages (even barely noticeable) on their stiffeners or they are completely deformed;

- stiffeners protrude too much;

- if the lines of the pattern on the front half are poorly defined, and there is also a blurring of the edges;

- scratches and other minor damages are noticeable on the surface of the panels;

- lamellas from one set differ from each other in color and brightness (such decoration will look inharmoniously and ridiculously on the walls);

- panels from the same set have different sizes (in this case, the technology of mounting the finish will be noticeably more complicated, since different-sized elements will not be fixed qualitatively).

Pay attention to the decorative layer of the panels. Any drawings, prints and paints should not be blurred and too dim. These features may indicate a low quality material. Such coatings will quickly lose their original appearance.

Nowadays, Chinese and European-made PVC panels are found in stores. European products are considered to be more qualitative.

When choosing a suitable material, it is necessary to pay attention to its density. It is from this parameter depends how durable and wear-resistant is the panel. This indicator is affected by the number of hard edges that are located in the inner part of the sheets.

The best indicators are:

- thickness of the front side - 2-1.5 mm;

- the number of ribs - 20-30;

- the total weight of the part is 2-1.7 kg / m2.

To ensure the reliability and strength of the material, you should press on it with your finger. The front side of the panel should slightly bend under its pressing, and then quickly return to its original state. If the lamella is strongly deformed, then it means that it contains a large amount of chalk - such materials do not last long and are very fragile.

Preparatory stage

If you decide to install PVC panels yourself, then you should stick to a specific work plan. If at each stage you do everything right, the result will not disappoint you.

To begin with, it is necessary to prepare the wall base for future facing with plastic. This work is especially important if you plan to attach PVC panels in a frameless way.

Algorithm works.

- First you need to remove the old finishing coatings and any items that may fall off the wall.

- It is also necessary to get rid of all defects of floors. If there are noticeable gaps or cracks on their surface, then they should be sealed with a suitable solution.

- Too prominent areas need to be cut.

- When the wall is aligned, and all the defects are eliminated, it must be treated with a quality primer with antibacterial components. Such coatings are necessary so that the substrate is protected from the formation of mold or mildew.

Only after all the work done on the preparation of the walls can you proceed to the design of the batten (if you use the frame method of installing the material).

Tools and accessories

To work on the installation of PVC panels, you need to properly prepare and stock up with all the necessary tools and accessories.

You will need these tools:

- a tape measure with a pencil or marker (indelible) to mark;

- hacksaw with small teeth for cutting sheet panels;

- construction level and plummet, so as not to encounter distortions and irregularities;

- triangle;

- plastic profile, slats for the design of the corners of the structure;

- screws, dowel-nails, clamps for fixing different elements on the base;

- screwdriver and hammer drill;

- sealing compound;

- glue;

- antiseptic.

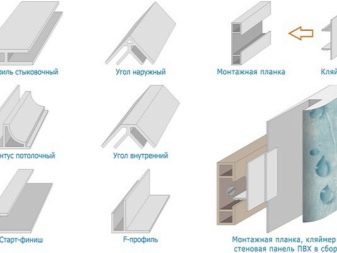

Also in the process you will need special accessories:

- external and internal corners;

- docking profiles;

- starting profiles;

- F-shaped profiles;

- ceiling and floor plinths.

All tools and fittings must be of high quality and reliable.

Payment

It is recommended to proceed to finishing work only after all the necessary calculations have been made. This step is needed to find out the exact number of PVC panels you need for wall cladding. Thanks to accurate calculations, you can avoid unnecessary overpayments due to the purchase of material with a large margin.

The fastening of PVC sheets implies their horizontal or vertical arrangement. In this case, the choice is only for the owners.

To calculate the volume of material vertically:

- you must first measure the entire room (that is, find out the length of the perimeter);

- then subtract the width of the window and door openings;

- Now the balance should be divided by the width of one PVC panel.

As a result of such simple calculations, you will receive the number of panels required for finishing the room. It is recommended to add a couple of additional units to the resulting value. It is necessary that you have a stock in case of damage to some parts.

As for counting the amount of material horizontally, it is carried out as follows:

- you first need to measure the area of the room;

- then the area of door and window openings should be subtracted from it;

- The resulting number should be divided into the area of one panel from the kit.

Add to the final figure of 10% - it will be a stock. It should be borne in mind that the horizontal display of plastic panels will have to cut, so you will remain in the form of PVC residues scraps.

Mounting methods

Installation of plastic panels can not be called too complicated. According to experts, it is quite possible to cope with such work alone, since PVC sheets do not have much weight.

There are two basic methods for installing such veneering materials. The first of them - frame. Choosing a similar installation option, you must be ready to make a reliable and high-quality crates, to which the plastic sheets will be attached. The second installation method is frameless. With this option, you do not have to make a separate frame, but you will need to carefully prepare the wall base for the future application of finishing materials.Otherwise PVC panels will not hold tightly and securely on the floors.

It is worth considering in more detail how the installation of PVC sheets in both cases occurs.

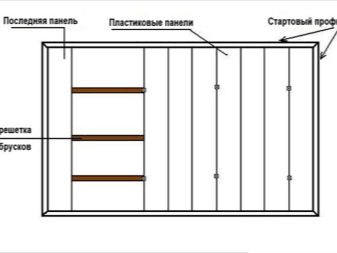

On the frame

When you have completed the preparation of rough overlap, you can begin to prepare a high-quality frame. It can be made of metal profile or wood. Both options are quite reliable and durable. However, if you want to build a wood structure, it must be additionally treated with antiseptic agents to protect it from rotting and drying.

Guide rails should be installed perpendicular to PVC panels. Simply put, if you are going to mount the sheets horizontally, the crate should be vertical and vice versa.

Frame bars should be mounted at a distance of 30 cm - this value is optimal in this case. These parts need to be fixed at the beginning and at the end of the wall, as well as around the door and window openings.

The frame construction under the plastic panels is recommended to be fixed to the bases on the dowels. Fasteners of 6x40 mm are inserted into the concrete floor (this is necessary so that a piece does not fall off on the other side of the concrete base), and 6x60 mm into the brick base.Fasteners are recommended to be installed, adhering to an indent of 50-60 cm.

The crate must be set in the same plane. - so plastic trimming will turn out smooth and neat. To achieve this effect, you can use small wooden linings or ordinary plywood pieces and install them under the framework of the frame. Do not forget that these elements must also be treated with antiseptics.

It is also permissible to use special perforated hangers, which are usually used for plasterboard ceiling structures. Such elements are necessary for exposing metal profiles in one plane, but they can be fully applied in the case of timber frames.

If you plan to use plastic profiles for the construction of the framework, then you should take into account one important nuance: these elements should be located only perpendicularly to the PVC panels. The slightest deviation can lead to many problems, for example, klyimery can not close and will not perform the main function. To avoid such errors, you should constantly check the vertical and horizontal.

Also, experts advise installing wooden frame elements around the perimeter of the room. the same thickness as the PVC profiles, since the starting panels will be attached to these bases.

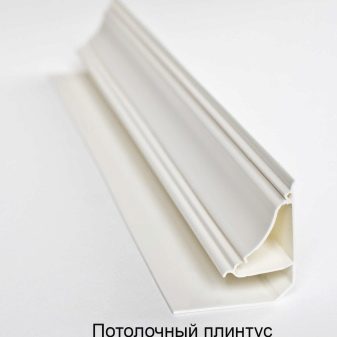

Further, at the level of the floor and ceiling, you should use a starting or ceiling plinth. The starting element is a narrow plastic strip. The ceiling plinth is a shaped part having a special cutout.

Laying PVC profiles must begin in one of the corners. (at the top or bottom). Fastening finish should be made on the slat frame. Fasteners are selected depending on the material that you used to design the battens. The result is a design that resembles a frame. It will be further inserted into the PVC panel.

Next, you need to cut the starting lamella in accordance with the length and height of the wall. To cut off excess pieces, you should use a hacksaw or a special metal saw. Cutting the panel, do not push it with your foot or hand too hard - push or break. To the first part correctly stood in the right place, you need to once again measure its length.Subtract from it 4-5 cm and cut.

At the starting strip, it is necessary to cut the protruding spike. After that, with the cut side, this part needs to be inserted into the corner profile, having tucked the edges into the upper and lower profiles. It is worth lightly tapping with the palm in order to drive the bar as far as possible.

Be sure to attach the level to the edge of the installed element to check its evenness. If the part is correctly, then we can safely fix it to each strap of the batten.

When you install the launch pad, you should cut off the second one, dock it with the first one and fasten it. Further actions are very simple and of the same type. Problems often arise only with the installation of the last lamella on the ceiling. Most often, this part has to be cut to the width, after which you need to try to fill it at the same time in the groove and in the profile (starting or corner). It is not always possible to do this carefully, since the plastic is easily wrinkled. To avoid such a problem, do not install a second corner profile. In this case, this part is worn on the fitted to the finish panel. Then these assembled elements fit in with the previous lamella.The profile is fixed only after these actions.

Further lining of floors with PVC panels is exactly the same.

According to experienced decorators, the frame method of mounting plastic panels is reliable, but more complicated than frameless.

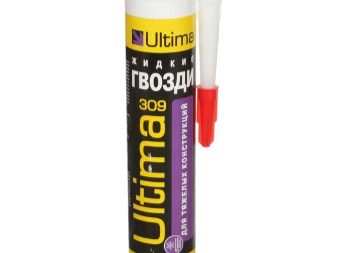

Frameless

In cases where the floors are smooth, plastered or sheathed with plasterboard, they do not need to install the batten for plastic finishing. In this case, it only takes the free space in the room. On such bases, PVC panels are attached using silicone, liquid nails or foam.

However, the launch panels in this case will still have to be fixed to the walls with dowels.

After that, they put on the back half of the sheets:

- foam (it is better to lay it on PVC sheets in a zigzag);

- silicone (it is recommended to put it on the panels in small portions at intervals of 10-15 cm).

Then the bar is slid into profiles and tightly pressed. After that, it is fixed with fasteners. Further installation of plastic panels should be continued on the same principle.

The main advantage of this installation method is that it takes a minimum of free time.However, it can be accessed only if the walls in your home have a perfectly flat surface without serious flaws. It should be borne in mind that in the future to remove such a finish without damaging the plastic is unlikely to succeed.

Recommendations

Facing the walls with plastic is not the most difficult job. The main thing is to follow the instructions provided and use quality materials / tools.

If you decide to make such finishing works with your own hands, you should take into account some recommendations from specialists.

- It is not recommended to combine PVC panels with more expensive materials. For example, the union of luxurious marble and PVC will look ridiculous and disharmonious.

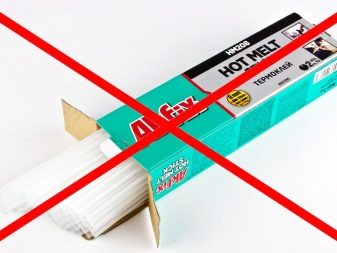

- According to experienced craftsmen, hot-melt glue cannot be used for PVC.

- To make a competent installation of the panels around the sockets, you must pre-make all the necessary holes for them in the material. Before this, be sure to turn off the electricity.

- If you have constructed a wooden crate in the bathroom or in the kitchen, then you should add a couple of millimeters to the indentation, because the wood is subject to deformation under the action of dampness, moisture and temperature changes.

- PVC panels are a popular and popular material, but they are not recommended to be laid in the bedroom (both for children and adults). For such rooms, it is better to choose more “breathing” materials.

- PVC panels are not recommended to sheathe the walls immediately after purchase. They should rest in a dry and warm room for at least 2 hours.

- To finish the walls should begin only after they are ready floor and ceiling.

- The advantages of polyvinyl chloride panels include their ability to hide various communications. However, these elements should still be accessible to the owners. To do this, use removable inserts.

- If you use liquid nails for fixing PVC sheets, then with the removal of their flows you should not pull - these compounds dry out very quickly.

- Materials for wall decoration should not have a different disclosure in the joints. You need to follow this by picking up plastic panels.

- At each stage of laying PVC panels, it is necessary to check the evenness of the structure with a level. This adaptation will help to avoid bevels and curvature of furnish.

- Experts recommend purchasing high quality PVC panels.Do not look for too cheap coatings - such materials are already available. Ask the seller certificates of quality canvases. Carefully study them. The composition of such finishing materials should not contain toxic compounds.

Design options

Polyvinyl chloride panels look organic in many settings. Designers do not recommend only to combine such coatings in one ensemble with very expensive and pompous coatings (for example, natural stone). Against the background of such finishing materials PVC sheets may seem too modest and even "poor."

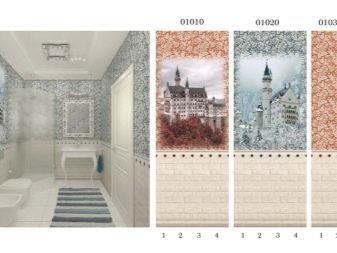

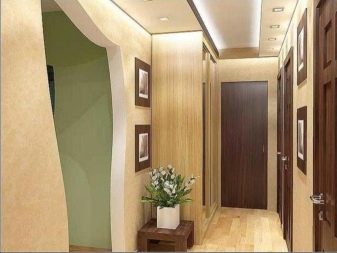

Plastic panels are able to revive the interior hallway, corridor, living room, bathroom and kitchen. The main thing is to choose a coating of suitable color and texture.

In the small loft-style kitchen, the dining area can be distinguished by PVC panels.imitating dark red brickwork. Against such a background, a laconic white table and metal chairs with dark wooden backs and armrests will look harmonious. The dining area will look complete if you hang a large dark clock over the table.

PVC panels can be used to decorate the apron in the kitchen.For example, in a room with burgundy walls, white floor and the same white set it will look spectacular apron, trimmed with a wide plastic sheet with the image of coffee beans.

In the hallway PVC panels are used most often. In such rooms, coatings that imitate brick and stone look particularly attractive. As a rule, they are adjacent to the usual wallpaper neutral colors. For example, canvas under a light brown stone will look harmoniously in tandem with yellow wallpaper and a wooden entrance door.

Also in the hallway or corridor conditions, PVC panels with a silk screen effect look good. Against the background of such light canvases, both entrance and interior doors of dark shades look advantageous. Such coatings look attractive, along with wooden furniture and decor items.

With the help of PVC panels you can revive the interior of the living room. In such environments, 3D coatings with embossed surfaces look particularly original and stylish. For example, with spectacular textured black canvases you can draw an accent wall with a TV, and place a dark chocolate woven sofa in front of it.To the ensemble does not seem too dark and oppressive, on the floor should put a light laminate.

For how to wall the walls with PVC panels, see the following video.