Basement siding "under the brick": choose the material for lining

Basement siding panels, made under the brickwork, are conveniently mounted to the surface thanks to the correctly chosen manufacturing format. In addition, this material can be applied on a wall already finished with another material. At the same time requirements for the quality of the working surface do not have strict criteria, as when finishing with other materials.

This property becomes especially relevant when the wall has serious defects, which cannot be corrected by insignificant means such as plaster.

The front siding imitating a brick is made on technology of polymeric molding. The raw materials for its manufacture are optimally matched to the operational features encountered by facade finishing materials.Panel "under the brick" - a relatively new material, produced by modern technologies on the latest equipment in accordance with European quality standards, which ensures a long service life and high resistance of products to various negative influences.

Advantages and disadvantages

When choosing a finishing material, it is important to consider the benefits of one or another type of finishing materials.

Basement panels "under the brick" have many positive qualities.

- Mass finishing. The low weight of the basement siding significantly increases the load on the building foundation, than brick finishing.

- Easy installation. The money and time spent on the installation of siding, at times less than similar work using stone or brick.

- Weak contamination of the site. Installation of panels is made with minimal pollution of the surrounding space, in contrast to masonry work using cement mortar, accompanied by high dust content and fine debris.

- Long service life. Modern production technologies provide a warranty period for panels up to 50 years.

- Easy handling. Siding is easy to clean and wash, does not require special conditions of care.

- Wide range of. Unlike analog materials, siding can imitate almost any texture and at the same time be the right colors, a pleasant appearance is maintained throughout the entire period of operation.

- Economic accessibility. The panels are cheaper than analog trim facing bricks, visually the appearance is almost identical.

- Preservation of air exchange wall. When carrying out installation works according to the established factory procedure, the finishing material will not interfere with the normal air exchange of the wall. This will affect both the pleasant "not suffocating" atmosphere inside the house, and the lack of dampness of the structures, contributing to their destruction.

- Additional insulation. The frame, on which the siding is mounted, allows to place insulating materials inside of itself, for example, polymeric wool, without additional work on the installation and finishing of insulation.

But also the basement panels under the brick have their weaknesses, these include:

- PVC is a fairly specific materialworking with which you need to take into account its ability to compress and expand under the influence of lower and higher temperatures, otherwise the facade finish will not last for a long time;

- some properties are weaker than those of analog materials: brick and stone, for example, strength or durability;

- externally, the plates imitate bricks well, but if you look closely at a close distance, it becomes clear that this is siding.

Specifications

From the operational point of view, basement siding under a brick has the following properties:

- it is steady against differences, maximum and minimum values of temperatures;

- siding is not porous, which causes its high moisture resistance, as a result of which the material does not dampen and does not collapse;

- Another consequence of moisture resistance is the absence of fungal mold on the surface of the plates;

- it is universal in circulation, it can be used in combination with other materials for finishing the basement;

- high resistance to aggressive phenomena of nature: snow, hurricane wind and other things;

- the color of the product does not tarnish and does not fade, while maintaining a pleasant exterior all the period of operation;

- strong and durable, does not stratify, does not crack in any operating conditions.

Kinds

Graduation basement siding occurs on the main component of manufacturing.

Vinyl

The main component is PVC (polyvinyl chloride), products are distinguished by a variety of size design and texture, which precisely bricks imitate masonry. When finishing the basement of the house with this material, it is necessary to take into account the property of vinyl to linear expansion, which should be reflected in the correct placement of the panels during installation. Otherwise, when the temperature differential neighboring products deform each other.

Other material features include:

- low weight provides an easy and simple installation process;

- products can be easily customized in size by cutting;

- high resistance to deformation processes;

- high heat insulating performance;

- powerful waterproofing properties;

- not subject to the damaging effects of ultraviolet and infrared radiation from the sun;

- resistance to extremes, upper and lower limits of temperature.

Metal

The main material is one of the metals suitable for these tasks: galvanized iron, steel, aluminum. Each option has its own advantages and disadvantages.

The features of aluminum include:

- the ease of construction, respectively, facilitates the installation process itself, and less material is needed to fix it;

- does not corrode;

- less resistant to mechanical stress;

- easy to color.

For steel siding panels are characteristic:

- high strength;

- susceptibility to corrosive processes;

- relatively large weight of the material, complicating the mounting panels.

Brick panels made of galvanized iron:

- does not give in to corrosion;

- relatively heavy, about 2.5 times heavier than aluminum, somewhat lighter than steel;

- relatively durable.

Cement

For the manufacture of panels used cement mortar with cellulose fibers, reinforced with synthetic additives. Fiber cement siding is obtained by pressing the mixture. Before installation, the work surface must be carefully prepared, otherwise the panels will not last long on the wall.

Characteristic properties of cement siding are:

- strength;

- frost resistance;

- resistance to weathering and sunlight;

- durability.

Selection features

When choosing a material that imitates a brick to finish the basement, it is worth considering some factors, including those that strongly affect the price of products.

The bulk of the cost of finishing panels forms the used raw materials. In foreign analogues: European or American, for the production of standardized raw materials used, certified and a lot of checks, respectively, the price of such products is much higher.

Also imported products after production must be transported over long distances, which ultimately leaves its mark on the price.

It is better to buy branded goods from the official dealer of the trademark - they will have the lowest price, and there is no risk to buy low-quality products without a guarantee. Prefer better to well-known brands, manufactured products in factories, and not in artisanal workshops.

The main indicator of the properties of basement panels is their compositionit is he who determines the operational properties of the products, if the domestic manufacturer uses good raw materials,the quality of such panels will be slightly inferior to import.

Brand manufacturers

Although the material is relatively new, there is a fairly wide selection of products on the market, the following manufacturers produce high-quality siding panels “under the brick”.

- "Dolomite". It produces panels with imitation of stone in three main lines: “monotonous stone”, “colored stone” and “exclusive”. The size of manufactured products is 30 cm x 22 cm with a thickness of 1.6 mm and a specific weight of 1.8 kg.

- Docke The manufacturer offers panels imitating the laying of bricks, stone and laminated sandstone. High quality at an affordable price have made this brand very popular.

- "Alta Profile". Russian manufacturer of siding panels. In the company's assortment there are products with the texture of bricks, layered stone and canyon.

- FineBer. Also, a domestic manufacturer from Novosibirsk, which offers siding panels imitating facing brick, made in red and yellow.

Calculate the required volume

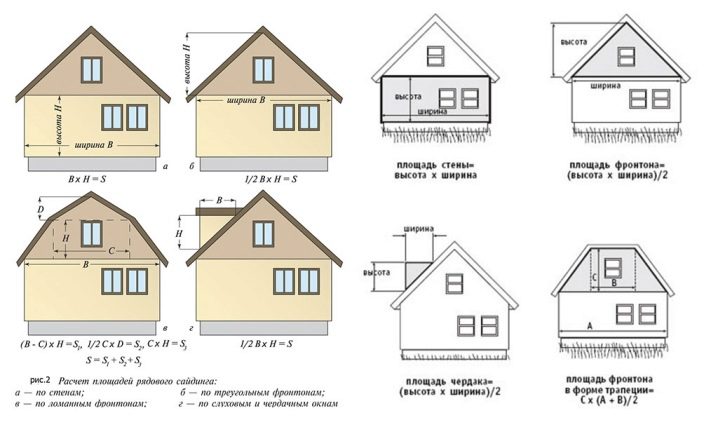

After selecting the brand of basement siding that meets all the criteria, you need to calculate the amount of material that will be needed for facing the house.

To do this, do the following.The area of the finished surface is calculated by multiplying the length and width of the base.

It should be borne in mind that during processing and installation of panels, the average material damage, in the process of fitting the plates, their sawn, chips and other moments, is about 10%.

Installation costs increase with an increase in the length of the surface to be trimmed., the same rule applies to facade plates, the longer they are, the greater the increase in trim. Profile and slats, from which the frame is constructed, do not have such problems, although they should not be bought too far.

To find out more accurate amount of material that will be needed to trim the base, you can contact the seller-consultant in the store or in the online support service on the manufacturer's website.

On how to disassemble the siding, so as not to disassemble the entire wall, see the following video.