Dimensions of the block house siding board

The variety of facing materials will turn the head to any buyer. To make the right choice, you need to know which material will serve your faithful service and will not let you down in any weather. The best financial solution for cladding the walls of various building and household structures is a material called clapboard or “block house”.

Special features

The house, lined with “block house” material, looks discreetly and concisely, but at the same time is very dignified and stylish, thanks to which “block house” is widely used not only in the exterior, but also when creating interior solutions.

Once upon a time, the question of what material the “block house” was made of did not even arise.Now there is a variety of modern materials for decoration for every taste, which represent a wide scope for creativity. Consumer properties, sizes, profiles, colors of the “block house” are not limited by anything, which makes it absolutely “flexible” when implementing any exterior consumer solutions, providing an excellent visual combination in various styles.

“Block house” is a panel that imitates timber, which can be made of various materials, such as vinyl, metal, MDF, natural wood and others.

Types of panels

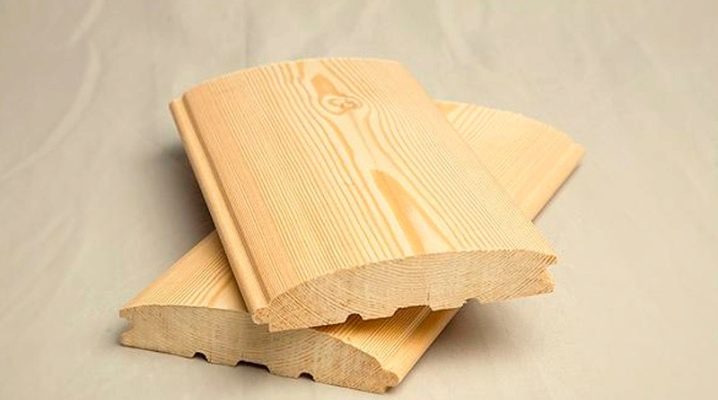

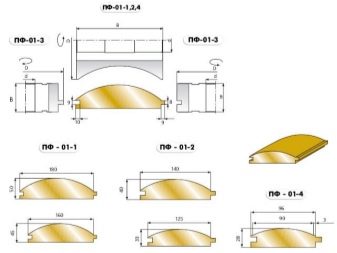

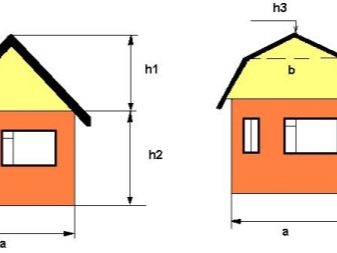

Wooden siding "block house" imitate a log, but is a board with a planed surface with a width of 80 to 150 mm and a thickness of 8 to 20 mm, characterized by the presence of grooves and crest. The most common samples are made of pine, larch, oak, linden, alder and others. The wooden “block house” is divided into the following types, depending on the destination:

- for interior decoration (approximate overall dimensions of the panel are 22x99x2100 mm or 22x99x3000 mm);

- universal (36x142x3000 mm or 36x142x 6000 mm);

- for exterior finish (36x1930x6000 mm).

The metal "block house" also imitates timber,but has a number of advantages in light resistance, fire resistance, is resistant to temperature extremes and unpretentious in care. The main area of its application is facing of facades. The approximate dimensions of the panel are 22x360x600 mm.

PVC "block house" is the most budgetary of all the above, but this does not prevent it from having a decent list of positive properties:

- resistance to temperature drops in the range from -50 to + 60ºС;

- resistance to the development of microorganisms when moisture changes;

- unpretentious care;

- service life reaches 50 years;

- approximate overall dimensions of the panel are 2x24x366 mm.

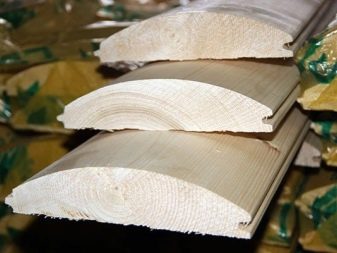

Wood panel production

At the first stage, the pre-treated log is sawn by the transverse or radial method. Then in the period from 10 days to 2 weeks (drying time depends on the initial moisture content of the tree) it is exposed to high temperatures. Then, using milling machines, the profile and the front surface of the board are directly formed. Next, cut the ridge and grooves. At the next stage, the product is faced and sorted.

Features storage of wooden options

Do not forget that wood is a very capricious material, so it is very important after processing to ensure optimal storage conditions, which will not lead to disastrous consequences. Wood must be protected from moisture.

To avoid damage to the panels due to moisture, the boards are packed in a special shrink film, forming bundles of several lamellae, while leaving the ends open to provide natural ventilation. It should be noted that the board, dried at natural humidity, is much less deformed and cracks. Dry board should have a moisture content that does not exceed 15%.

When choosing, pay attention to consumer characteristics and cost. Dry lining costs 25–30% more expensive due to the cost of drying, but at the same time it is less cracking or deformed.

Considering the quality and characteristics of various types of wood, it is planned to divide the panels into varieties or classes (A, B, C). This separation is carried out depending on the state of the wood, the presence of resin pockets and knots fused together.

The data on the category must be reflected on the package “block-house”.

- A - for every 150 cm length, one knot, two resin pockets and two non-through cracks are allowed;

- B - for every 150 cm length, no more than four knots, two resin pockets and two non-through cracks are allowed;

- C - permissible cracks, pockets, larger knots than in other categories.

The highest quality "block house" belongs to class A.

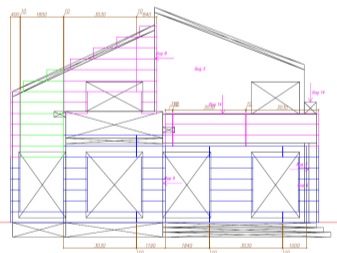

Stages of fastening panels for house trimming

When covering the house, you must follow simple rules and act consistently.

- Before starting work, the material must undergo acclimatization (accept the properties of the environment in order to avoid further deformation, cracks and distortions). For outdoor work, the adaptation period is 2 to 3 days; for interior work, the minimum period is 5 days.

- Thermal insulation and vapor barrier of the exterior walls of the building.

- Preparation of the "block house". Surface treatment panels quickly and deeply penetrating protective agents. For grooves and spikes, this procedure is recommended to be performed twice.

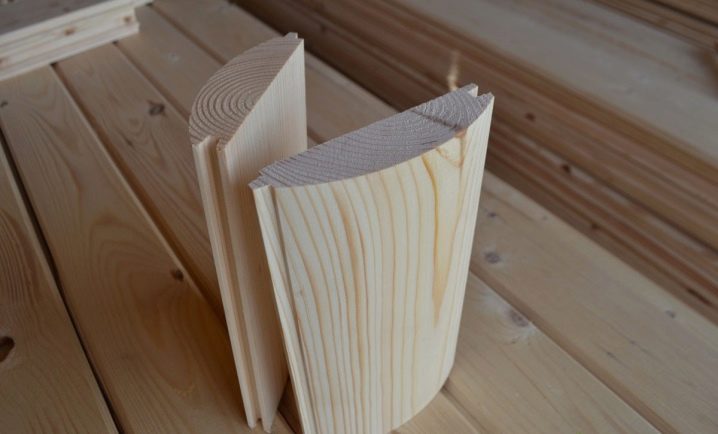

- Directly installation of the panels starts from the bottom of the wall and leads further upwards according to the principle “thorn into the groove” (the thorn is up, the groove is down). Fix the "block house" to the wall can be screws, studs or special brackets.When changing the temperature and humidity of the panel can change the density of the material, so it is best to attach the cloves, because they do not interfere with small displacements.

After finishing the lining, it is necessary to re-apply the protective layer on the panels, then renew the coating every five years.

The secrets of the masters

In order to reduce the total amount of work, it is recommended to use wide panels for the external lining of the building, which will give the house a stylish appearance. Such panels are difficult to distinguish from this bar. We must not forget about natural ventilation, retreating a short distance before installation. When re-applying a protective layer, special attention should be paid to the seams and joints.

For exterior cladding, it is recommended to use a flat “block house” of coniferous species, and for interior cladding - from hardwood. It is not recommended to use wide panels indoors. The estimated cost of finishing work may vary depending on the characteristics and material of the "block house".

How to choose?

To select the best panels made in accordance with Russian and international standards, and save yourself from unnecessary costs, It is necessary to pay attention to a few points:

- It is worth starting with an accurate calculation of the required amount of material, which directly depends on the characteristics and size of the “block house”, not forgetting the error on trimming.

- Greater competition among manufacturers in the Russian market does not mean that there are only high-quality panels that correspond to the declared grade. You must carefully inspect the purchased product for obvious defects (cracks and other damage). But here there are some difficulties - you can not unpack the goods if it is packed in film. You can see only the panels located at the edges. Inside the packaging, boards may be hidden that are deformed from moisture and improper storage.

- To check for the presence of curvatures, 2–3 panels are connected to each other, taking into account that there should not be a rigid fixation. If possible, be sure to measure the moisture level of the material.

- Panels should be cut along the growth of the tree trunk, and annual rings should not protrude from the board in order to avoid splitting. The edges of the boards must also be checked to ensure that they are smooth and without cracks, which are signs of rejection.

- Particular attention should be paid to the "block house", built up in length (milling of several parts of the board). Sections can be of unequal length, fitted according to the pattern or type of sawing, the connection can be made with glue.

- It is worth paying attention to the presence of mold and other microorganisms.

Any curvature, cracks, irregularities and distortions make the panels unsuitable for use and installation. It is worth checking the connecting grooves.

Cost of panels

The cost of the block house panel depends on several factors, of which the tree species and the geometric parameters are determining. For the manufacture of used rocks growing in the region of production. However, custom-made for an additional fee, you can order the manufacture of any material. The cost of tree species that are common in the middle lane is in the range from 150 rubles per m² (pine) to 1250 rubles per m² (oak species).

Classes (A and B) in Russia are very difficult to distinguish visually, respectively, and their price is 20–25% more. The price for class C is much lower. Additional cost for 1 m² for class A will add forced drying.

Useful tips

It is recommended to pay attention to a few highlights.

- "Block-house" 300 mm can be called the most popular and versatile finishing material to date. It is represented by panels of wood, metal, vinyl.

- Due to the variety of materials from which it is produced, even the most demanding consumer will find a worthy option that matches personal preferences and capabilities. Among the variety presented, you can choose a panel of wood, metal or vinyl.

- A wide range of characteristics allows you to use the "block house" as for exterior finishing work with a large temperature difference and high humidity, and for interior decoration.

- When choosing a particular type and class of “block house”, it is very important to carefully inspect it, eliminate deformations, and check for the presence of chips and cracks.

- During installation, it is necessary to comply with certain conditions and not to forget about the acclimatization of the material, treatment with protective compounds and natural ventilation, in which case it will last more than a dozen years.

For information on how to communicate the house "block house", see the following video.