Standard sizes of lining

The decoration of country houses and country houses with wooden “lining” gives them a cozy, nostalgic look both inside and outside. A selection of wooden trim parts of different texture, shape and quality of materials can have many options. And thanks to the skills of designers and builders, the house will become a masterpiece of wooden architecture.

Where used

In the manufacture of the first passenger cars, due to the low tractive characteristics of locomotives of that time, it was required that the weight of the train corresponded to these capacities. Then it was proposed to make the casing of the wagons of boards of a special form, which provided a certain tightness of the wagons. From here and the name "Lining".

Clapboard sheathe or trim various rooms. This is a material for interior lining of rooms, terraces, balconies, loggias, baths, dressing rooms, verandas. Looks good at home with a blockhouse and American exterior cladding. There is a growing need for lining the country house construction and the private sector, finishing apartments and office space. Every year the number of proposed new forms and profiles of wardrobe boards increases.

Special features

Lining is a milled, most often wooden board, which is widely used in the construction and decoration of various household premises. This is not a recycled product, but a solid material made of wood, specially treated for convenient assembly when covering walls, ceilings and other components of housing and utility rooms. The lining material contains no harmful impurities, with the exception of anti-decay agents and the effect of wood parasites.

All finished products in the form of clapboard must comply with the standards adopted in the EU and Russia.

The main dimensions according to EU standards:

- thickness;

- width (useful);

- length;

- spike size.

The starting material for the production of this type of products are coniferous trees (pine, spruce, larch), as the cheapest and most affordable for processing and use. But for expensive claddings, hardwood is often used.

It must be remembered that conifers, especially spruce and pine, emit tar when heated strongly, therefore different species should be combined to trim the baths to eliminate unpleasant sensations.

For the facing of baths and bath rooms they use a whole set of tree species from which lining can be made. A special place here is lime. Its universal and healing properties make it an ideal bath option.

Essential oils released from linden during heating have many healing properties, including anti-inflammatory and anti-bacterial. Stay in the steam room, trimmed with lime, relieves colds. In addition, the linden resists moisture and maintains a long-sanded surface.

Kinds

According to the purpose, shape, section, relief, methods of assembling the lining can be different options that have already been used for many years in construction practice. Also, there are new forms that offer designers and developers of building and finishing materials. Different types of wood are used in different ways.

Larch - the most durable wood materialwhich occupies the top lines in popularity among those who live in houses trimmed with wood.

On the plots near the country houses, the walls of houses, porches, gazebos, verandas are trimmed with larch lining. Larch porch can decorate a house of any format. In terms of environmental friendliness, this breed of wood is beyond doubt. When sheeting exterior surfaces, the attractiveness of the house only increases. Moreover, the external and strength characteristics of larch lining are preserved for many years.

Excellent finishing material - alder. Like linden, it has healing properties, it is perfectly polished, it retains external characteristics for many years. The tree is not afraid of moisture, in contact gives a feeling of warmth, so sitting on an alder finish in the bath will be very nice.

Wall cladding creates an atmosphere of coziness and comfort. Each species of wood used for the production of boards-wagon, has its own characteristics. Beautiful decoration of the clapboard at home and inside and outside gives the dwelling a unique design.

Area calculation

To calculate the desired area does not require complex calculations.Installation when finishing surfaces inside and outside is often done independently, and everyone who took up finishing their house is able to calculate the working area and the number of wagon boards. There are calculators that count the number of lining.

The required dimensions are added to the planning table, a calculated quadrature is obtained and divided by the effective area of a single strip. Get the amount of lining for the required coverage area. It will be better and more reliable if you add to the results 10% of the calculation. Such data will be accurate for rooms with the same height of walls.

Calculation examples

For facing the attic, its area is calculated, consistently carrying out several actions:

- the whole area is divided into components whose area is easy to calculate;

- a table of all measured data is compiled;

- all separate areas of components are added up;

- the total area is divided by the size of the useful area of one lining strip.

To the resulting number of lanes, add 10-15% for trimming, taking into account the complexity of the room configuration. The received number of boards of lining will be sufficient for performance of facing.

Standard sizes

It is interesting that the size of the wood clapboard is also influenced by the tree species. In practice, such species as pine, larch, cedar, linden, alder, oak, aspen are used more often than others to make this material. Species of the breed affect the difference in the cost of material from them. If you correctly make all the calculations, then there will be no overpayment for the purchased volumes of lining.

Below will be given the basic data board-lining: width, length, thickness. Knowledge of these sizes make it possible to choose the optimal number of boards lining.

There are some differences in grades:

Aspen

Lining of aspen most often finds application in the decoration of baths, saunas, canaenas. It is produced and supplied to the market by Russian and European enterprises. Imported products are characterized by increased requirements for quality, humidity and size conditions. All requirements are laid down in the European standard DIN 6.

Our GOSTs are less demanding in quality, so the material is slightly cheaper, but both standards are the same in size:

- thickness: 12–40 mm;

- width: 76-200 mm;

- length: 0.2 m (minimum) - 6 m (maximum).

- thickness: from 12.5 mm to 15.0 mm. (lining - 12.5 mm);

- useful width: 88 mm;

- total width (size);

- length: from 1000 mm to 3000 m.

Oak

Oak lining differs in durability, wear resistance, beautiful and noble texture. Residential and service objects trimmed with clapboard from oak are distinguished by their natural appeal.

Standard sizes of such lining:

- thickness: from 12.5 mm to 15.0 mm. (sometimes it happens - 14 mm or 12? 5);

- width: from 50 to 108 mm (determined by the manufacturer);

- length: from 1000 mm to 3000 mm. (most often 3000 mm, 2700 mm, 2500 mm, 1800 mm.

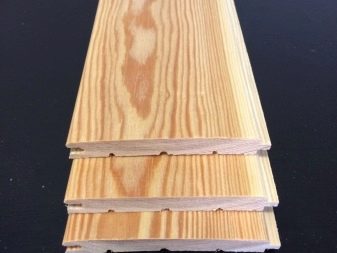

Pine

From pine blanks produce the bulk of the lining. The ease of processing and storage at a low price make the material available to most buyers.

Dimensions of pine wall paneling:

- thickness: from 12.5 mm to 15.0 mm. (13 mm are popular, or 12.5);

- width: from 50 mm to 108. (determined on production);

- length: from 500 mm to 3000 mm. (Preferred - 3000 mm, 2000 mm, sometimes up to 6 meters).

Larch

Along with the standard dimensions of conventional wall paneling, enterprises can also produce wall paneling with data other than standards. However, standard indicators are more often used in construction practice.

Wooden lining standards:

- thickness: 12–40 mm;

- width: 76-200 mm;

- length: 0.2 m (minimum) - 6 m (maximum);

- spike size: 4-5 mm.

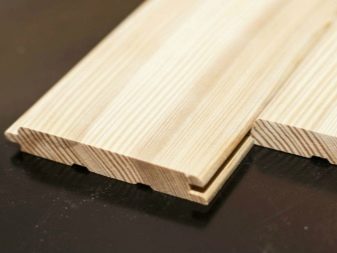

Standards of wooden eurolining:

- thickness: 13, 16, 19;

- width: 80, 100, 110, 120 mm;

- length: 0.5 m - 6 000 mm;

- thorn size: 8-9 mm.

Tolerances:

- thickness: 0.7 mm;

- width: 1 mm;

- length: +/- 5 mm;

- spike size: +/- 0.5 mm.

A simple board of the lining type has a fairly large range of parameters, its thickness is in the range from 1.2 to 2.5 cm, width - from 8 to 15 cm, length - from 60 cm to 6 m.

The EU standard is limited in thickness and width - 12.5x96 mm and uses 4 lengths:

- 2.1 m;

- 2.4 m;

- 2.7 m;

- 3m.

At Russian enterprises, other sizes may be varied for mass use: thickness - 1.3; 1.6 and 1.9 cm with a width of 8, 10, 11 and 12 cm, the length is limited to 6 meters.

Sometimes, by separate orders, manufacturers make lining with specific dimensions. (thickness - 20 mm, width - 120 mm, 125 mm, 140 mm). Euro-rail boards undergo chamber drying, therefore the standard moisture content of the material is maintained, which should be at the level of 10-15%. Conventional boards lining to such moisture is not adjusted, and it remains at a level 2 times higher than the European level. This affects the quality, but reduces the cost of production. Drying in special chambers is very expensive in technology and finance.

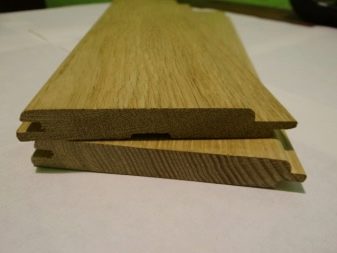

The main parameter by which you can immediately distinguish eurolining from the usual board-lining, - the size of the spike.In eurolining it occupies 9% of the width of the board (or 8 mm), in a conventional board-clapboard the projection is shorter - from 4 to 6 mm. In the boards made as lining according to EU standards, grooves are made from the rear sides for the passage of air. This prevents the formation of condensate and removes the internal voltage that may occur when temperature drops.

Difference of eurolining from lining:

- Accurate fulfillment of quality requirements.

- Dried in the chambers boards eurolining have a moisture content not exceeding 12%. In the usual lining this figure is in the range of 15-28%.

- The outer surface of the boards is polished and does not require further processing after lining.

- Each package with boards is packed in plastic wrap.

- Grooves for ventilation and condensate drain more.

- The size of the eurolining thorn is 9 mm, the usual - 5 mm.

Tips and tricks

When selecting the exact number of wardrobe boards (for useful area, width, pure size without a spike), remember that a short board costs less. So, 1 m3 of board with a length of 1.7 meters is almost 1.5 times cheaper than a standard board from 2.1 meters to 3 meters. When covering there are places of inconsistencies, it means that you need to take care of which one to choose and order a corner for final finishing.

The optimal number of boards-wagons calculated by the useful size (without spike). The shorter the length of the board, the lower its price. Therefore, for the choice of lining the dimensions and price remain the defining parameters. The total financial costs will depend on the surface area to be clapboard.

The outer surfaces of the premises are sheathed with a special clapboard, which is called "Block house". One side of this original lining is rounded. The execution of such a surface requires special equipment to get the same size and shape of the surfaces. The details of the blockhouse assembled in a particular decoration create the impression of a log house made of well-rounded logs. A feature of blockhouses is the possibility of replacing damaged elements in case of need without violating the integrity of the entire finish.

A special type of lining - "American". In fact, this is a planed board, in which a groove is cut from one end, and a tongue is formed on the other, this allows you to firmly connect them together. Chamfers on the side edges of the board create a type of masonry from wooden beams, you can not immediately guess that this is an “American” finish.

Although the purpose of this is also lining, but because of the impressive appearance, strength, width,its weight is used only for exterior plating. The house after finishing an American takes the form of a solid timber structure. Of course, if you wish, you can also use the material for interior decoration, but in this case a part of the interior space of the room will be reduced.

The total usable area of the entire workpiece must be calculated very carefully and carefully, so that at the end of the work there is no need for an urgent addition of the missing number of carriages due to poor calculations or the appearance of a large number of unusable elements.

On how to choose the right wall paneling, see the next video.