Purpose and principle of operation of general ventilation

Outwardly, ventilation may look like a simple unit, and therefore people do not particularly think about its structure. It is extremely important to understand how it acts, what a block is. It is advisable to find out before buying and installing devices in order not to waste money.

What is it and what is it for?

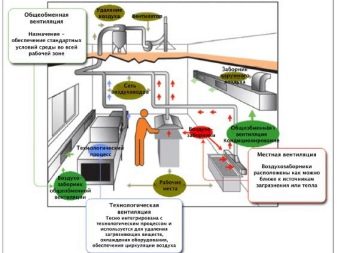

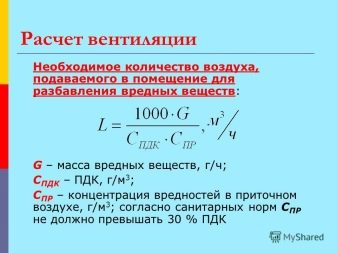

The purpose of general ventilation is to ensure a stable circulation of air masses throughout the volume of the room. It is used if substances harmful to the room and human health:

- directly into the air in the room;

- disperse throughout the volume;

- cannot be removed for any reason by local means.

The discharge of harmful substances includes:

- toxic gases;

- water vapor;

- substances that create a bad or just a pungent smell;

- dust particles;

- excess heat;

- waterlogging.

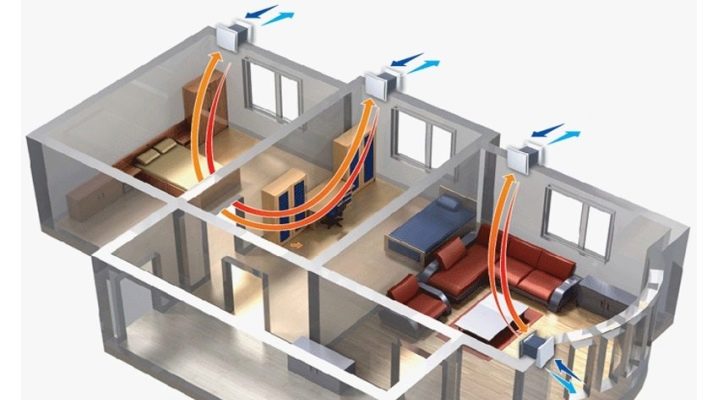

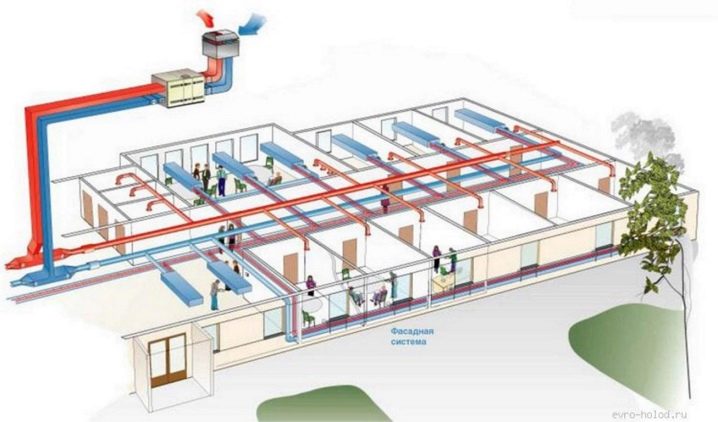

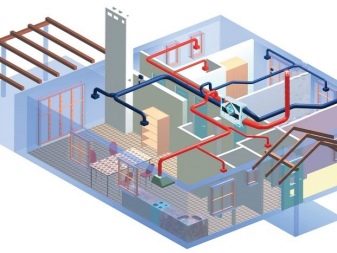

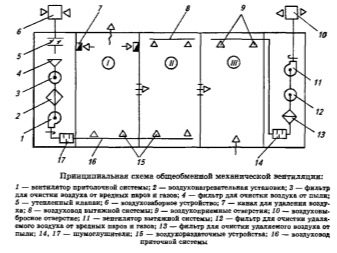

General ventilation has exhaust and intake components. This ensures the simultaneous removal of contaminated air masses and the flow of fresh air. The exhaust must work in such a way that when the air is replaced with a new portion, the contamination remains within the standard parameters. In most cases, the design and configuration of the system is set to move the same amount of air in and out.

An exception is made for situations where it is necessary to get rid of bad smelling substances or gases harmful to health - in this case more gas is extracted than it enters.

The main area of application of general exchange ventilation is those rooms where the temperature and humidity are excessively high. It copes with the purification of air much better than local options. It so happens that the heat is not enough. In such a situation, mount general supply air-supply complexes with mechanical drives and heating units are mounted.But since heating is accompanied by an increase in dust concentration, additional filters are installed.

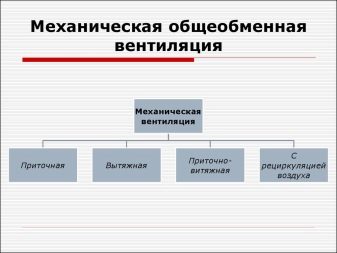

Types of systems and basic characteristics

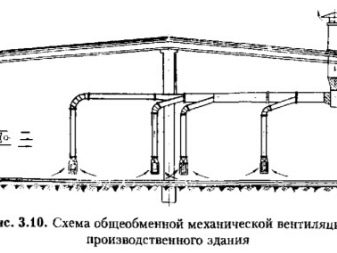

General industrial ventilation of industrial premises, as well as the local exhaust structure, is selected taking into account the explosive and fire category of the production facility. The distinction is made on the following indicators:

- driving force (natural or forced);

- flow movement (input or output);

- the presence or absence of channels.

Regardless of this division, it is required to strictly observe the sanitary standards adopted in the Russian Federation. Even systems with a mechanical push of the air flow begin to count and design with the definition of natural thrust. To accurately describe it, you need to consider:

- the level of difference between external and room temperature;

- differential pressure between the rooms and exhaust hoods installed on the roofs;

- wind speed.

The simplicity of natural ventilation is seductive for many people, since it can be mounted without being connected to the electrical network.Subsequently, very expensive energy will also not be used. However, direct attachment to the parameters of the environment is reflected in the functioning of the system is very bad. Even with a slight deviation of the situation from the norm, it begins to work significantly worse than is required to ensure a hygienic atmosphere. Therefore, in most cases, the artificial version of general ventilation is much more perfect than the “natural” counterpart.

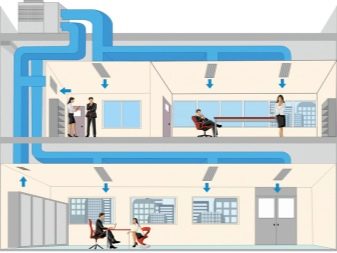

In practice, they try to get away from the two extremes, applying the mixed version as actively as possible. Due to the fans, the flow of purified air masses is organized. In order to leave the polluted part of the atmosphere, slots and doors are used in the general exchange ventilation. The air escapes through these holes by itself. Since the air pressure becomes excessive when air is supplied, it most effectively goes to the outer space.

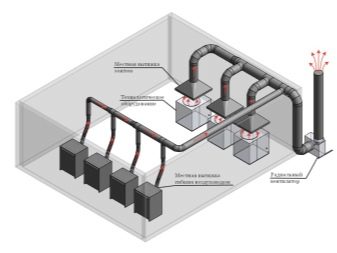

Often, general ventilation ventilation of the inlet type is supplemented with special filters. Selection of the degree of cleaning is done individually. Modern filtering equipment allows you to block the penetration of pathological microorganisms inside.Examination of pulling ventilation systems shows that they act on the reverse system. The supply is organized naturally by ventilating either from adjacent parts of the building.

The outflow is achieved by the use of fans, chasing the air through the system of discharge channels. General exchange ventilation achieves the best results where:

- local pumps are inefficient;

- the ingress of harmful substances into the air is associated with poor sealing of the main parts of the system;

- To find specific sources of contamination of the atmosphere with toxins does not work.

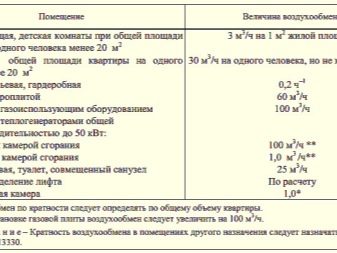

Making lists of the main sanitary and hygienic standards for the ventilation of any premises, it is impossible to show the slightest self-will. Solid instructions on this subject are contained in regulatory enactments and SNiP. It is recommended to design and install all dissimilar ventilation systems at the same time as the building itself, taking into account meticulously the specific features that the future object has and even its individual parts.

To accurately determine the category of equipment required, it is necessary to find out, first of all, how much air will need to be supplied and pumped out to create a comfortable, pleasant microclimate.At the production, information about temperature, humidity and noise regimes, emissions of harmful substances is also taken into account.

The correct choice and fine tuning of the ventilation systems are evaluated by the level of noise effects. It should not reach the interfering level, when it becomes impossible to live or work fully. But the deviations from the normal installation almost inevitably turn into strong noises. Situations when airing complexes contribute to the clogging of the atmosphere by any extraneous substances are also categorically unacceptable. To simplify the work of ventilation systems, they quite widely resort to automation: the larger the serviced area, the more relevant it is.

But it is important to understand that automation requires a serious attitude, because the slightest mistakes in its selection, installation and adjustment of modes lead to a distortion of the normal balance, to the movement of dust and dirt between individual zones. Often incorrect settings of automated ventilation can be recognized by the chaotic distribution of bad odors.

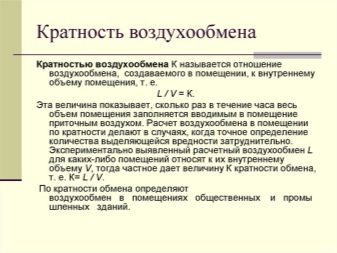

If, when setting the regime, the regulatory requirements for the multiplicity of exchange of air masses are violated, almost inevitably there will be a staleness.Therefore, only trained professionals should be engaged in automation of ventilation systems.

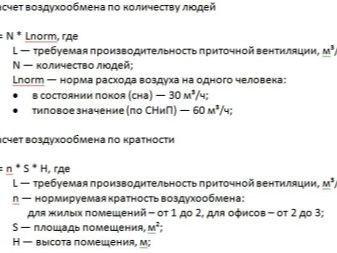

The multiplicity is calculated as the proportion of the volume of air passing inward to the total volume of space. The real multiplicity is often made variable so that it flexibly adapts to the number of people in the rooms, the temperature and the humidity of the air.

It is automation that allows you to effectively vary the frequency of air exchange - it is impossible to achieve the same success with manual control. Therefore, in reality, complex management complexes are not a waste of money, but real assistants to property owners.

Experts note that automated ventilation:

- minimizes the need for self-adjustment of the system;

- allows you to reliably protect the electrical circuit and the equipment connected to it from all voltage surges, short circuits, freezing;

- facilitates and accelerates the search for defects in technical systems;

- allows you to specify the mode of operation in general and in individual rooms, distribute the parameters over time;

- corrects not only the temperature of the air, but also the amount of toxic gases, the humidity of the atmosphere.

Automatic systems are able to inform people about the need to change the oil inside the compressor, to clean the air ducts, the current consumption, and the air pressure in the ventilation ducts. Sensors allow real-time collecting information about the state of the monitored object. The digital code supplied to the displays is set by the converter. Along with sensors, regulators are invariably used. They are usually of two types: devices for controlling the speed of air flow and devices for setting a certain temperature.

Automation shield is another essential component. It allows consumers and specialists to intervene in the work of the system using special algorithms. It is on the boards that the current information about the current state of the equipment is displayed, and through it, commands are given for manually starting or shutting down the ventilation system.

Selection of specific devices and methods of their interaction with each other in hardware and software should be carried out by technologists, because no one else can make the right decisions.

Air exchange calculation

Even in the case when the removal of dust is very important, it is necessary to eliminate the difference between pumping and removing air more than 15%. When calculating the air exchange through general exchange ventilation, one should focus primarily on the evacuation of excess heat and on reducing the concentration of harmful substances to acceptable values. What are these values in practice, detailed in GOST 12.1.005-88. For the whole territory of Russia, the normal temperature of the air entering the room is 22.3 degrees - this is the parameter that the ventilation must be adjusted to.

To determine the amount of heat that must be removed outside, make up the heat balance. Be sure to consider it:

- Sun rays;

- people in the room;

- cooling hot items.

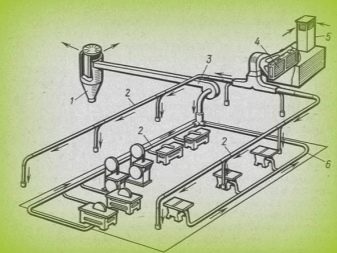

Device layout

When designing the design of general ventilation attention should be paid to:

- pipelines and channels;

- air receiving chambers;

- nozzles for inlet mass;

- throttle valves;

- valves for adjustment;

- filter units;

- pulling shafts.

Tips masters

It happens so that it is necessary to install long exhaust air ducts.When their length exceeds 30-40 m, it is undesirable to install an axial fan - it is required to use centrifugal devices. In kitchens, it is necessary to ensure the air exchange rate is 9 or 10 times. At the same time for 1 person who is constantly in the room, you need to submit approximately 60 cubic meters. m of air. It should also be borne in mind that at least 1 kW of heating equipment in a kitchen should have at least 70 cu. m of air per hour.

Types of ventilation systems are discussed in detail in the following video.