The process and subtleties of ventilation certification

A passport for ventilation is even more important than for a person. This is not only an analogue of an identity card, that is, a description of the type of systems, but also a reflection of all the slightest features and nuances — about the same as all documents describing someone, along with a detailed biography.

What?

A passport is the only legitimate justification of the formal right to create and operate a specific ventilation system. This document shows that the full cycle and scope of work has been completed. And not just made, but in strict accordance with regulatory requirements and project materials. Just according to the passport registration of the purchased air equipment takes place. It frees owners from the need for tedious certification of foreign ventilators.

It is the passport that becomes the decisive evidence in disputes with control authorities. If the building is clouded with smoke, if the passage of air into the adjacent rooms is weakened, or if noise or vibration occurs, the controllers will demand that a document be presented. Then, according to the passport, it should be clear that the reason is not related to violations of work or structural defects of the installed equipment. Also, certification becomes evidence of the correctness of the installation work.

For your information: before handing in passports, all ventilation mechanisms will be tested, even if they have a full set of federal certificates.

General requirements for the ventilation system

The survey process can only be constructed so that all the information that is specified in SNiP 3.05.01–85 is disclosed. First of all, you need to check whether there is the slightest deviation from the project. The explanations in the spirit of “there was no tool and therefore I had to turn the channel a little to the side” of professional appraisers would not be exactly interested. All air ducts that pump very humid air should not have lower longitudinal seams. Segments that can be covered with dew, necessarily mounted with a slope to the draining line.

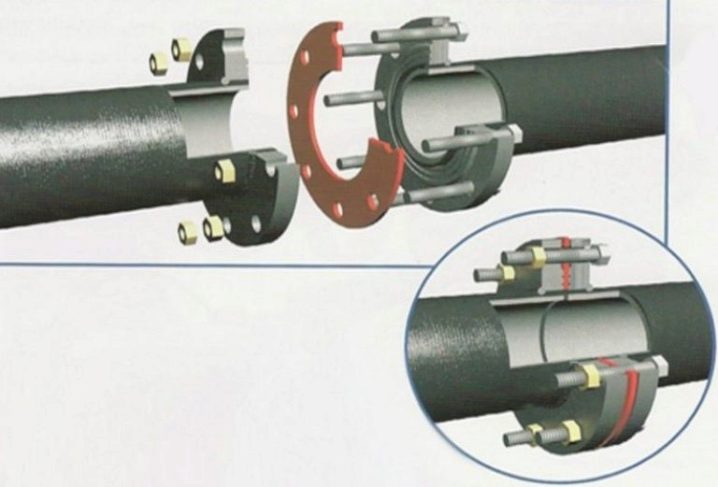

Normal slope is from 10 to 15 mm per 1 running. m. in length.Flange docking involves removing the gasket to the outside. It cannot be directed inside. As for the gasket material, it should be selected for specific temperature parameters. So, if the air is heated to no more than 70 degrees, you can use foam rubber and a rope made of polymer mastic.

But to use these substances with more serious heating is impossible. It is required to use elements on the basis of asbestos - a cord or a cardboard. Sometimes the air moves through the air ducts filled with acid fumes. Then you have to use resistant varieties of plastic. The list of materials providing tightness of joints without flanges is noticeably different.

At relatively low (no more than 40 degrees) air temperatures need a sealed tape. Up to 60 degrees round pipes should be covered with cuffs of thermal shrinkage. If the air gets hotter (up to 70 degrees), you need to apply mastic special samples. As for the flange joint, the bolts must be tightened thoroughly. Nuts must be placed on one side only.

A vertical flange is supposed to tighten the nuts on your own. If the product is mounted horizontally, it is required to place fasteners from below. Connections without the use of flanges: if the largest side of the pipeline is limited to 40 cm, then the step should be made up to 4 m, and with a larger face it is reduced to 3 m. , but not to the flanges themselves.

To connect the air duct with the fan, it is necessary to use only such an insert that is able to block the spread of vibration. Most often, glass fabric constructions are used in its role. Such parts are mounted immediately before testing the characteristics of the created system. To seal the socket can only be bundles of hemp, which are impregnated with asbestos cement mixture with the inclusion of casein glue. It is important: sometimes after such a treatment, voids still remain - asbestos-based mastic helps to remove them.

It is forbidden to leave the gap from the radial fan inlet pipe to the impeller of the same fan by more than 1%. Also the deviation of a shaft from a strict horizontal is inadmissible.The exception (vertical orientation) is characteristic only for fans placed on roofs. Electric motors and impellers are oriented coaxially, and if the fans transmit force through a belt drive, the axles of the pulleys should be set in parallel. Turning and switching all vent valves should be as easy as possible, even if no tool is used.

The list of works performed during certification

Since all measures during certification are aimed at finding out strictly standardized information, only typical procedures are performed. It is categorically impossible to do, as already mentioned, without deep testing of ventilation systems. First of all, they study the design features and the practical state of the air supplying systems. They must fully satisfy both the official working draft and the standards.

Thereafter:

- understand, whether the tightness of the hidden areas is not broken;

- they look at the operation of the main part of the equipment at idle;

- make sure that the fans have the characteristics stated in the documentation (or do not have).

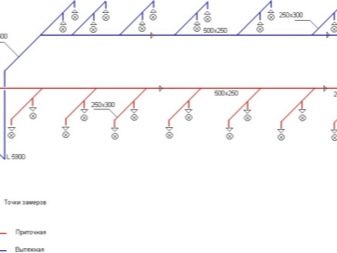

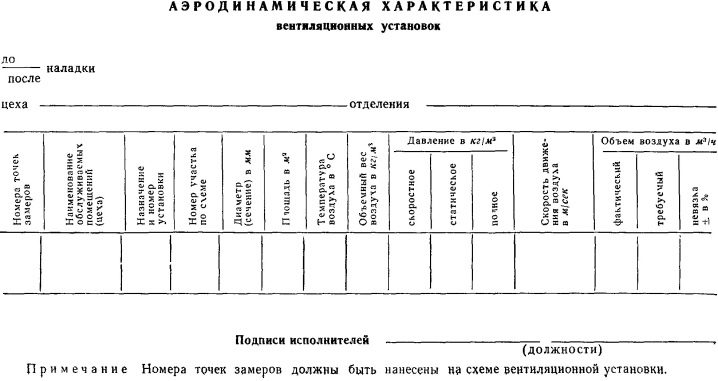

The next step is to check the efficiency of air exchange through ventilation, in fact, and whether it meets design standards. Important: supervisory authorities can and should also check the natural circulation in order to find out if the information on the basis of the project is correct. Measurement of the volume of sound that occurs during ventilation is carried out at several points. Where they are - determined in advance using special calculations. This is more to the acoustics and deserves a separate discussion.

Paperwork

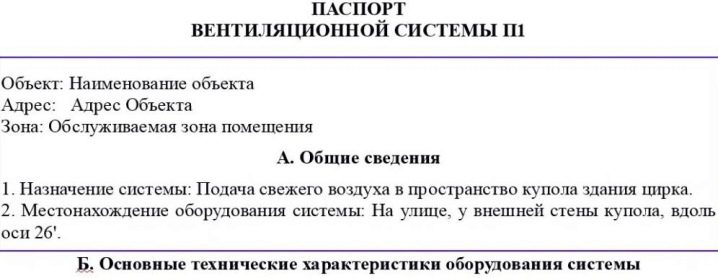

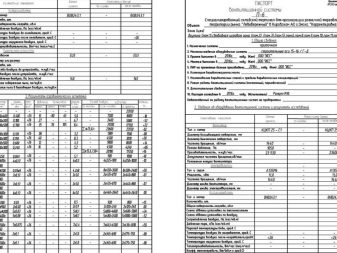

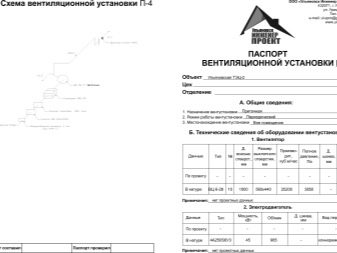

On the ventilation system

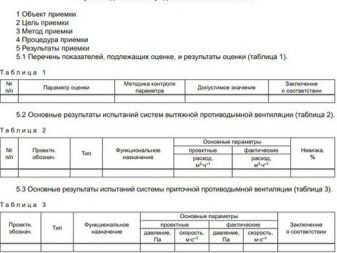

The list of information that should be recorded during ventilation certification is described in SNiP 3.05.01–85.

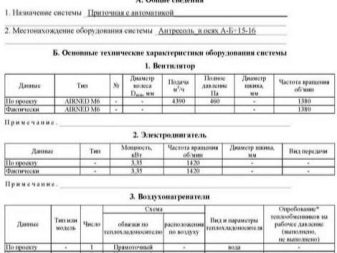

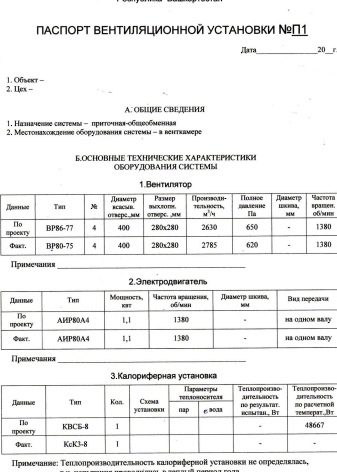

In the category of general information fall:

- type of object;

- its location;

- purpose of ventilating means;

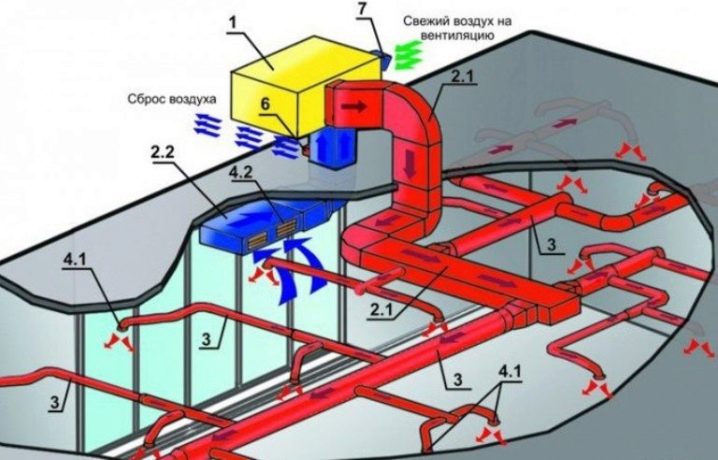

- placement of ventilation equipment at the facility.

To the ventilation unit

The content of this section of the technical passport strongly depends on what kind of engineering system is described.

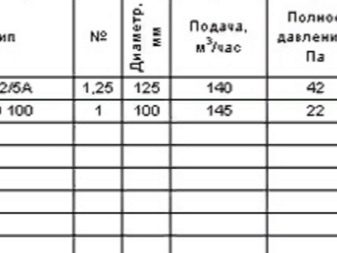

So, for any fan indicate:

- what type it is;

- how fast it spins;

- how big the impeller is;

- what is the volume of the driven air;

- limit pressure indicator;

- pulley diameters (only if power is transmitted through the drive belt).

Where there are fans, there must be electric motors. In the passport they write down what type they are and how they transfer the effort to the working part. More should be reflected power and torsional speed of the rotor. Of course, the view must be specified for both heaters and air conditioners. But with respect to them, it is necessary to further describe what kind of coolant is used, as shown by checking heat exchangers at regular pressure, exactly how air and coolant flow occurs.

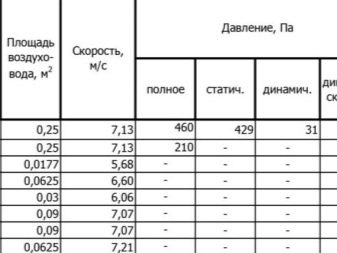

In addition to all this data, they enter in the passport:

- air duct sections;

- total air costs;

- whether it responds to the information specified in the project or not.

Features of the document

Knowing all the above is very good - no one argues with this. But for the customer of the works or for the owner of the building, other circumstances are more important. It is important for them to have clear criteria in order to understand whether the passport of the ventilation system presented by the contractor is correct.You also need to know what to write into this document yourself, and what should not be entered. There are three types of passports of ventilation, officially recognized.

The first type is the so-called building one, the second one is made up during operation, and the third one applies only to installations that purify gases. Additionally, you can make passports that take into account the specific moments of a particular industry. But this is a completely different topic. "Construction" passports are compiled whenever commissioning works are carried out. Important: this is required even in the absence of adjustment as such, because otherwise the operation becomes illegal.

Characteristic signs of a poorly written document will be:

- full coincidence of design figures and actual data (in reality this does not happen);

- no notes;

- an abundance of empty graphs (those who do not know enough about the adjustment of ventilation, are forced to let them through so as not to demonstrate their incompetence);

- reference to testing without specifying their specific date.

If the customer of the passporting detects at least one of these signs, he has the right to return the document to the contractor and to demand rework or return of the paid sums.On the title page (although it is not always) describes the identification information about the object. Passport cap contains an indication of the setup organization. Information about it should allow to fully identify this structure. Allowed (albeit optional) placement of corporate symbols.

If the organization has passed the accreditation, it will necessarily report the number of the certificate confirming this fact. This number will be needed later - to draw up test reports. He justifies the legitimacy of each conclusion. Regarding the type of ventilation system, he must sign in full, indicating passports for exhaust and inflow, for a humidifier and other components. In the future, it will be easier to navigate in such a document and controllers, and operational services.

If the number of installations exceeds 50–70, devices of the same type by designation may be indicated in the documentation in color font. No standard regulates this, so the choice of color at its discretion. Although the construction practice involves writing the address of the project, for state inspectors it is better to show the act, which indicates the real address of the building.Important: it is also worth noting the legal address of the contractor (along with the actual one), which helps to gain the favor of the controlling authorities. If you do everything in good faith, you should immediately provide for a reserve of free space, where the results of the efficiency tests will be reflected.

The problem of the construction form is that it reflects a number of information that is unnecessary for practitioners, while not including really important information. Most often, this drawback is eliminated through the use of notes.

For fans indicate:

- numbers assigned to the plants;

- full typical names of the ventilating installations different from names of fans;

- adjusting the control blocks or speed, corresponding to the passport parameters;

- other installed equipment;

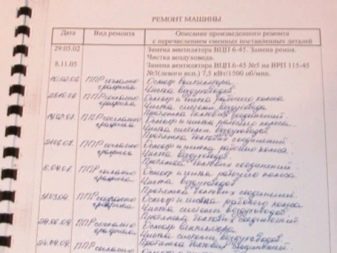

- information about repairs (if they occurred).

The passport must be accompanied by protocols recording the results of the tests. Typically, construction practices do without them, although this is just a common omission. In some cases, you can add instructions for use of the ventilation system (if it is something different from the usual). We are talking only about brief instructions (up to 1 sheet).Full instructions sometimes include up to 30 sheets, no need to attach them to passports.

Passport to exhaust devices are reduced, if there is no section on the air heater. But the documentation drawn up in production often grows due to information reflecting the replacement of individual units and modernization work. A complete reflection of maintenance alone requires several pages.

As a result of the test, protocols are also added to the passport reflecting:

- results of the aerodynamic test of the fan;

- tightness of pipeline channels;

- noise level;

- vibration intensity;

- overpressure.

Hint about conducting a test of the effectiveness of ventilation systems - in the video below.