Features of plastic ventilation grilles

Arrangement of ventilation is unthinkable without a fence conclusions from it. The air should pass there freely, but at the same time it is obligatory to sift out all the pollution, block the penetration of insects and small warm-blooded animals. One of the best options for solving these problems is the barrier grilles made of plastic.

Advantages and disadvantages

Plastic ventilation grilles are actually an indispensable component in air supply systems. With their help, a certain course of the air flow is confidently set. The penetration of garbage from the house or from the street is excluded. Thanks to these elements, the appearance of the room as a whole and its individual walls is complemented. And also it is possible to avoid reverse thrust,if the design is supplemented with a check valve.

The question may arise: why are polymer structures for ventilation best suited?

- low price (even with a hole for the hood);

- ease;

- ease of installation and subsequent use;

- graceful appearance;

- minimum cleaning labor.

But this does not mean that it is possible to use such gratings in any case for attic without a grid. They have a number of serious weaknesses. At considerable heating the plastic melts easily. It also has low strength (in comparison with metal products). These two factors significantly limit the use of plastic gratings in industrial and energy facilities, as well as on the street findings of home ventilation.

Forms and sizes

When selecting plastic gratings for ventilation, one must first of all be guided by the appearance of the air ducts, where they will be mounted. Along with rectangular and round elements, there are also oval and square details. But the practicality of such blocks is in doubt, and in some cases they are not suitable at all.Often used octagonal or half-oval lattices. If some other configuration is required, the product will have to be ordered additionally.

For the most part, such sophisticated devices differ not only in unusual geometry: they are given a special color. It is important to take into account the fact that the size of the lattice in the specification differs from its actual size. The fact is that the specifications are drawn up on the basis of the typical dimensions of the openings, and this refers to the openings indicating the size of 95x95 cm (or any other values). And because the landing clearance is somewhat smaller than the stated figures. Otherwise, there is a great risk of failure during installation.

For most manufacturers, the gap on each side is 0.15 cm. That is, the total difference between nominal and real figures will be 3 mm. The smallest permissible value is 5 cm. This is due not only to production difficulties, but also to the fact that a very small lattice does not perform its task well.

The recommended size is as follows:

- external elements in standard design - up to 1.5 m in width and up to 3 m in height;

- fortified version of external grilles - up to 2.5 and 3 m, respectively;

- reinforced lattice type with additional hardening of the lamellae - up to 3 m in height or width (but only if the size of any side is up to 2.5 m).

The bulk of plastic gratings has a length of from 10 to 100 cm. Their width varies in the same range. But the thickness is the same everywhere - 1.5 cm. If the thickness differs from this value, there is a non-standard product. We repeat that these amendments have not yet introduced corrections for the landing openings, these are just nominal values.

Species

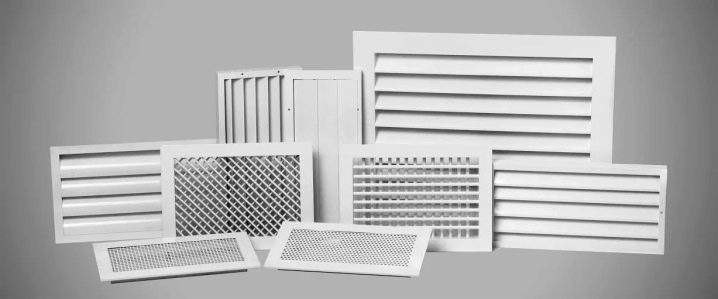

A very important role is played by the functionality of specific products. Many designs are not customizable, but there are adjustable varieties. Particular attention should be paid to those elements that can normalize the flow of air from the outside.

Also available:

- versions, supplemented by a non-return valve for effective blocking of the return thrust;

- modifications including insect screen;

- Internal filter designs that effectively clean the incoming air flow.

It is necessary to use adjustable external structures when systems are created that ensure the supply and removal of air, heating and air-conditioning complexes.The experience of using such products in the residential and office sector allows us to give them positive ratings. The essence of the adjustment lies in the fact that the slope of the lamellae changes, and after that, the feed rate and the course of the air jet are corrected. The use of linear gratings is resorted to in the case when it is necessary to distribute supply or exhaust air over a rather long area. Such constructions can be mounted not only in ducts, but also in walls or in suspended ceilings.

A slotted type with fixed adjustable parts is required when organizing both supply and exhausting, and even combined ventilation. The role of the inertial grids is to replace the check valves. Through them only the air going out is moving. The counter flow is blocked by special gravity blinds. The name of the transfer grids speaks for itself: they are needed wherever there is a need to support the movement of air from one part of the building to another part of it.

In addition to decorative properties, the geometry of the grids has an important practical importance. So, round products help to equally effectively supply air, pull it out, form a stream. The cylindrical format allows the flexibility to adjust the inflow or outflow.In a special form highlighted ceiling structures that are needed where the entrance to the ducts is located on the ceiling. In some cases, used grilles with increased ability to absorb noise.

The role of such elements is to compensate for the inability to install typical ventilation systems that quench extraneous sounds. A feature of the overhead grilles is that they are not rigidly embedded in a wall or other part of the building. These parts are mounted on top of the hood opening using self-tapping screws. In some cases, self-tapping screws are replaced with liquid nails. The choice of mounting method is determined by the individual features of the surface.

Materials

Plastic gratings for ventilation are mainly made from PVC profiles, for which they are used, the method of stamping or pressure casting is used. Polystyrene has become quite widespread.

The advantages of this material are obvious, since it:

- is inexpensive;

- easily survives ultraviolet radiation;

- very resistant to aggressive environments;

- mechanically durable.

In general, the same characteristics have the designs of polyvinyl chloride. However, they are already somewhat more expensive.The disadvantage of these two plastics is that their resistance to harmful factors is not suitable for all conditions. The solution to the problem is the use of advanced plastics - ABC and especially ACA. The first option is characterized by an increased mechanical strength, and the second is very well tolerated by the effects of a bad atmosphere, and intense ultraviolet radiation.

Installation

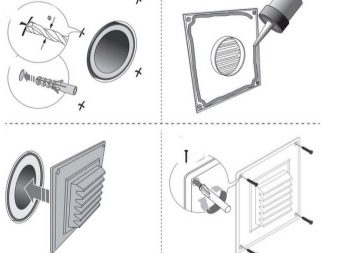

As already mentioned, the size and configuration of the installed gratings should ensure the closure of the aisles to the ventilation shafts. It is this consideration, rather than aesthetic priorities, that comes to the fore. In kitchens and bathrooms, it is best to install gratings in which lamella placement can be adjusted. If you want to block the hole in the door, it is advisable to give preference to narrow parts. They successfully perform the task and do not prevent the flow of air from one part of the house to other rooms.

Prior to installation, it is required to prepare the installation site and clean it of all contaminants. Begin work with a mark of attachment points. Accurately on the selected positions put dowels.When they are embedded in the wall, it's time to fix the structure already on the screws. Important: if the grille is equipped with a non-return valve, it should be oriented as precisely as possible. Since plastic products are lightweight, in many cases they are mounted on glue, while decorative versions best tolerate such an installation.

Glue lubricate the surface exactly on the contour. Then put a sealant on the grid. Now it is required to press as close as possible to the surface. For your information: it is worthwhile to attract an assistant who will control the accuracy of the installation with a building level in his hands Silicone adhesive will harden after 180 minutes. After that, you can remove the excess of its usual sharpened knife.

Greater popularity deserved mount on struts. But it is important to consider that this method is suitable only for individual modifications. If it can be applied, there is no reason for concern for the quality of the docking. Where it is impossible to seal the joint of the ventilating complex and the grill, it is necessary to put special adapters. To eliminate problems with a very large structure, so that it does not fall off suddenly, you need to use special elements.

See below for how to install the plastic ventilation grille in the bathroom.