Fire dampers for ventilation: variations, design and principle of operation

People and organizations are constantly taking steps to reduce the risk of fire. But prevention is not always effective enough, otherwise the need for emergency services would not be so high. In the meantime, their units rush to the challenge, it is necessary to reduce the intensity of flame propagation, and the solution of this problem is impossible without fire dampers for ventilation.

Special features

For any kind of technical systems related to safety in the event of a fire, strict adherence to norms and standards is even more important than for “ordinary” things. All the main technical standards are aimed at ensuring that the ventilation system remains free from gaseous and solid combustion products longer.

Another important task, which is being solved by the developers of flame retardant complexes, is how to increase the resistance of products to high heat. Therefore, quite a lot of attention is paid to the selection of materials and verification of their thermophysical properties. The duration of preservation of qualities at a certain temperature is also officially fixed.

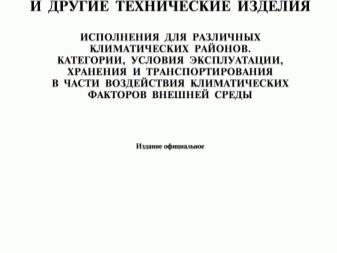

The state standard for fire ventilation systems was developed in 1969.

The requirements of GOST 15150 indicate that when using such devices:

- the design thermal regime must be strictly maintained;

- Do not allow dampers to come in contact with moisture, whether condensing or otherwise flowing;

- it is also necessary to prevent the wetting of the control units and the exterior.

It is strictly forbidden to use devices that do not have adequate protection for pipelines that remove corrosive and corrosive substances. Also, such devices can not be put where the concentration of corrosive reagents in the air leads to the loss of the corrosion resistance of buildings.

It is customary to single out:

- normally open valves;

- normally closed valves;

- smoke devices;

- open and sealed blocks of explosion-proof execution.

Official standards adopted in Russia

According to the requirements of SNiP 41-01-2003, all fire-prevention devices without exception must be installed. This act indicates that the so-called normally open valves should be installed on pipelines that exchange air with the external environment. They are suitable for air conditioning, air heating equipment. Also, such systems are needed for supply and exhaust ducts that serve automated fire extinguishing devices. As soon as the anti-smoke valve closes, the automation starts the operation.

This mechanism can be started in manual mode. Shutdown can also be manual, although by default the control unit opens the valve when the sensors record the cessation of a fire. As for the double action apparatuses, they are necessary both for the ventilation of houses and for the purification of buildings from burning products. Depending on the design, such devices can be launched by a command of fire extinguishing installations or by a signal from an autonomous control unit.The second option is used if an autonomous system is used to protect the premises.

The use of anti-smoke valve and other systems that allow you to quickly release the room from the smoke, necessarily everywhere where a lot of people gather. Also, such systems should be mounted in any warehouses. It is generally accepted practice that after installation, protective equipment should be thoroughly tested. All design work determining the type, number, location of fire dampers and the modes of their operation should be conducted in accordance with SNiP 21-01-97. The complete design cycle should be completed before construction begins.

Additional Information

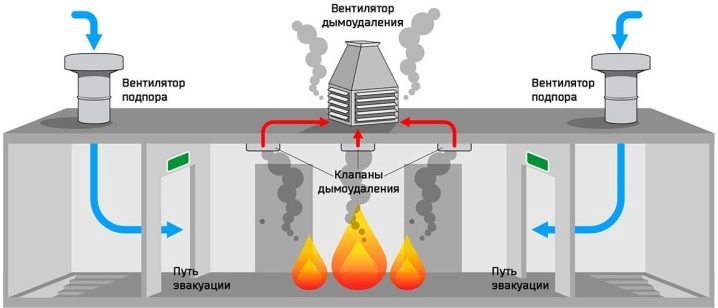

The principle of operation of the fire ventilation valve is also fully determined at the design stage. In this case, the static technique is simpler than dynamic isolation. In the first case, the operation of the ventilation system simply stops. Because of this, the smoke cannot reach the neighboring premises, and that part of it that has already penetrated the outside gradually dissipates and does not pose a particular threat.At the same time, blocking the supply of oxygen to oxygen from the outside inhibits the spread of fire.

For customers, the static scheme is most beneficial for installation. But its low reliability makes this advantage less valuable in practice, since there is a high risk that the equipment will not cope with its task.

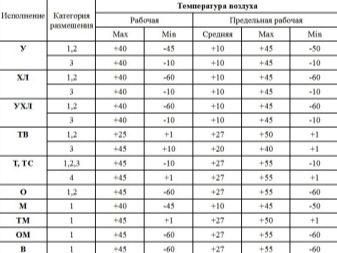

In dynamic systems, the valves are assisted by fans, which are activated by a command of the sensors. With the natural method of removing the smoke, smoke is drawn through the lights and smoke hatches. Attention: according to official requirements, smoke can be removed only from one source, that is, valves in other rooms will remain in the initial position.

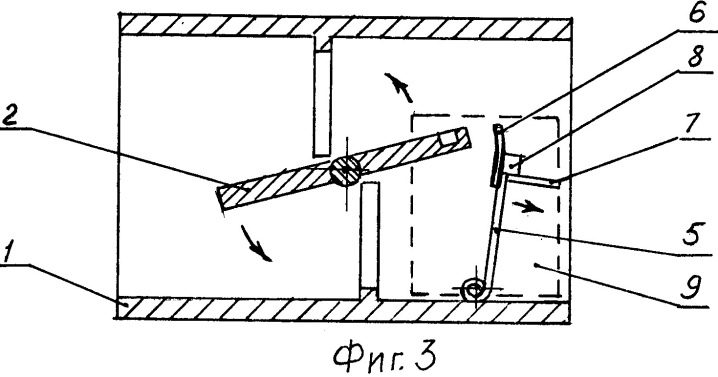

By itself, the valve does not differ increased complexity. In the metal case hides the valve, if necessary, blocking the lumen. Its start is carried out by means of the drive. As for the lattices, which equip some models, their role is limited to just the external design. Valves are divided into fastened inside walls, as well as channel ones, which are installed in the ventilation shaft.

Drives are diverse in performance. In addition to electromagnetic and electromechanical devices, standard solutions based on the action of springs are often used. After connecting the installed valves, it is mandatory to check the operation of the system as a whole. The commissioning works are completed with aerodynamic tests, the results of which are noted in the protocol being drawn up in a special form. It is quite reasonable to combine such tests with a training fire alarm.

Depending on the design, the type of drive used is different. So, with a reversible electric drive, flange devices that remove smoke are usually supplied. But restraining the spread of fire systems for the most part are equipped with return springs. When selecting engines for torque, it is necessary to focus on the area, which according to the standard has a damper for air. Most developers prefer to make the control signal the disappearance of voltage, which provokes the movement of the leaf of the electromechanical apparatus from the initial state to the working position.

To keep the sash in the initial position consumes very little electricity. For your information: some of the actuators are equipped with thermal indicators, due to which the system is triggered if the heating inside the valve reaches a critical value. And in reverse models, the movement of the valves occurs due to changes in the circuit of the supply chain. The undoubted superiority of reversing systems is due to the fact that they cannot accidentally operate if the power is suddenly turned off for any reason. That is why such blocks are recommended for supply and exhaust devices.

A visual demonstration of the operation of the smoke removal valve - in the video below.