Channel fans for round ducts: device and features of operation

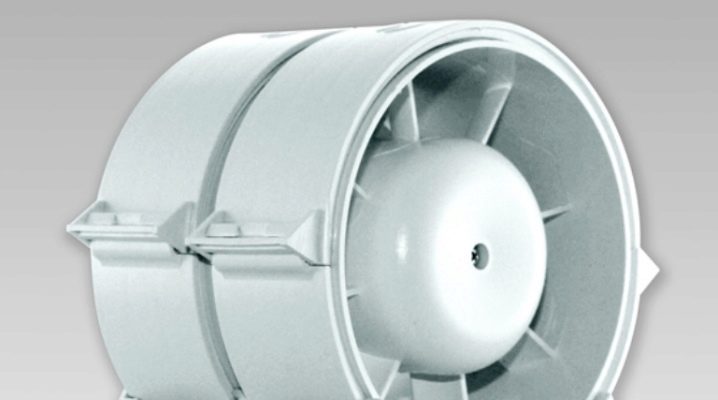

Channel fans for round ducts are a common type of exhaust equipment and are widely used in the construction of ventilation systems. Devices are used both in household networks and in industrial installations and have proven to be simple and reliable devices.

What are we for?

Ventilation is an integral part of modern communications and ensures the removal of exhaust air from the room and the influx of clean air into it. The simplest type of ventilation system is the exhaust design, which works by means of natural draft, arising from the difference between external and internal temperatures. However, such installations are not suitable for full air exchange and quick removal of polluted air.

In this case, it is advisable to use full-fledged forced-air and exhaust installations.operating due to the forced circulation of air masses. In order to provide artificial traction, duct fans are installed in the ducts, which are perfectly suited for this purpose. Due to the simple design and long service life, channel models have found wide application in all types of buildings and structures, ranging from kitchens to hot shops of industrial enterprises.

Advantages and disadvantages

High consumer demand and popularity of duct fans due to a number of indisputable advantages of these devices.

- Small dimensions and low weight allow you to install models in any air ducts, including flexible and plastic.

- The devices are highly reliable, durable and do not need regular maintenance.

- Due to the absence in the design of complex mechanisms, devices can be mounted in any spatial position.

- The dimensions of the fans are fully compatible with the diameters of the ducts, which greatly simplifies the selection and simplifies installation.

- The devices have a fairly wide range of operating temperatures. Domestic models are able to function in the thermal mode from -40 to +60 degrees, while the upper limit of smoke removal devices is +600 degrees.

- The fans are equipped with a speed regulator, which allows you to change the intensity of air exchange independently. In addition, the devices are able to work in both inlet and exhaust systems.

- The power supply of the fans is carried out from a normal electrical network of 220 V. The models do not require the laying of a power cable and can be operated in conjunction with other types of devices.

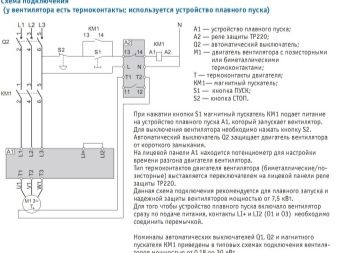

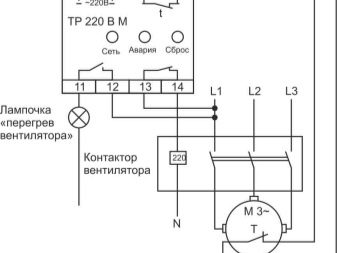

- The fan motor is equipped with thermal contacts that open an electrical circuit when the device overheats excessively.

- The case of channel fans corresponds to the high class of insulation IP44, which makes the operation of the device stable and safe. When working, some types of units do not produce any noise, which allows them to be used in residential premises.

- The high efficiency of the devices allows to significantly save energy, which distinguishes the channel models from their analogues.

- Low cost and wide consumer availability make channel fans even more popular.

The disadvantages include the inappropriateness of devices for air flow polluted with solid and fibrous particles. This significantly reduces the scope of their application and does not allow the use of models in the manufacturing industry and weaving workshops.

The principle of operation and operation

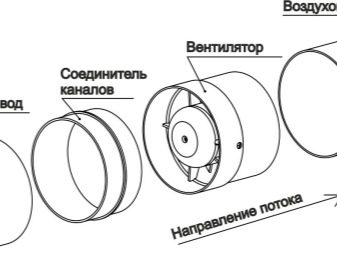

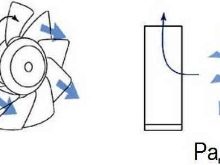

The essence of the fan is to capture the passing air using blades and create a discharged space, where the air masses are drawn in and then pushed out. Due to its versatility, the devices can work as a supply device, and when the unit is rotated 180 degrees - as an exhaust. This allows equipping supply and exhaust systems with fans of the same type, which simplifies the acquisition and, if necessary, repair. Installation of the device is made in the duct rupture without the use of additional console devices.

The operation of channel fans does not require scheduled maintenance and preventive measures. Devices work fine for a long time and do not break. The main conditions for trouble-free operation of the units is compliance with the manufacturer’s recommendedmodes of operation, such as the degree of contamination, the temperature of the exhaust air, the level of humidity. In addition, when choosing a model, you should carefully familiarize yourself with its technical characteristics.

For home use, purchase medium-power, silent models with backward curved blades. This design feature significantly reduces the noise level and allows you to use the device in a residential area. However, if you want to purchase a powerful unit, then the installation of flexible inserts at the fan inlet and outlet will help reduce the noise load. If the device is supposed to be used in industrial installations, then a model in which the blades have a bend forward is suitable. This greatly increases work efficiency and increases efficiency.

Features and varieties

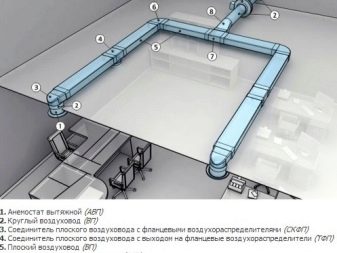

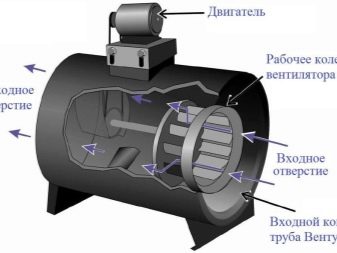

Channel fans for round ducts come in two varieties: radial and axial. Axial models with the help of blades capture and promote air masses along its own axis. A distinctive feature of such devices is low aerodynamic drag and low power consumption.Radial (centrifugal) models are equipped with spiral blades, with the help of which they capture and move air masses into the casing, from which they go under high pressure into the duct. Such units have a large suction power and are often used to service large rooms.

In addition to the design, duct fans are classified according to a number of signs.

Purpose

The most common type of household and industrial fans are intake models. They are widely used for arranging supply and exhaust ventilation systems and are installed in long ducts.

The next type of duct fans - smoke removal devices, are an important element of fire protection systems and are installed in emergency ventilation ducts. The units are characterized by high power and allow in a short time to make a complete replacement of the air in the room. The main characteristics of smoke-removing models are their reliability and ability to operate at temperatures up to +600 degrees for an hour.

The heat-resistant qualities of the devices are due to the protection of the electric motor from overheating, which becomes possible due to the design features of the device. Fans of smoke removal are designed in such a way that the stream of hot air does not interact with the body of the electric motor, which is reliably protected by the impeller sleeve. The installation of smoke removal fans in permanently operating systems is not recommended. The device is designed for short-term, but very powerful and effective work in emergency situations, therefore, during normal use, it can lose some of its performance.

Heat-resistant duct fans, unlike smoke removal fans, can work not only in emergency systems, but are also used in regular installations. Models are intended for ventilation systems of baths, saunas, fireplace halls and for work in hot production workshops.

Another type of channel fans - silent models can be separated into a separate category only conditionally. Products with low noise levels are present in both inlet and heat-resistant and smoke-removing devices, and the level of noise load depends on the design of the fan and its power.

Silent are models in which the sound level does not exceed 25 dB.Such products are recommended for installation in ventilation systems of residential premises and public spaces. Models whose indicator exceeds this threshold are considered noisy and cannot be applied without taking additional measures to equip noise insulation in apartments and houses.

Material

The body of the duct fans for round ducts is made of galvanized sheet steel with a zinc coating thickness of 20 or more microns. From the inside, the steel casing is coated with an anti-corrosion compound, which allows the use of models for pumping air with admixtures of aggressive chemical compounds. On top of the device can be covered with heat-resistant paint, which increases the protection of the metal from adverse environmental conditions. In addition to the metal version, there are models with plastic cases and blades. Such products have low power, low productivity and are designed for home ventilation systems. In the manufacture of models with sound insulation, mineral wool is used as an insulating material, which has undergone a pressing procedure and has a thickness of at least 5 cm.

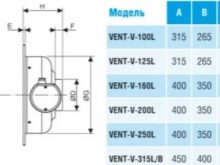

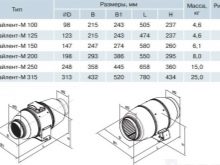

Dimensions

The classification of duct fans according to the size of the section is fully consistent with the classification of ducts. The most common and popular are models with a diameter of input and output equal to 100, 125, 150 and 160 mm. Such units are most in demand in household systems installed in apartment buildings and private cottages. Models with a diameter of 200 and 250 mm are often mounted in the ventilation systems of shopping centers, cinemas and exhibition complexes. These are, as a rule, quite powerful models capable of providing full ventilation of rooms with large crowds. Overall units with a cross-sectional size of 315 mm are used on serious high-performance installations of industrial enterprises and have high power and large working life.

Professional Tips

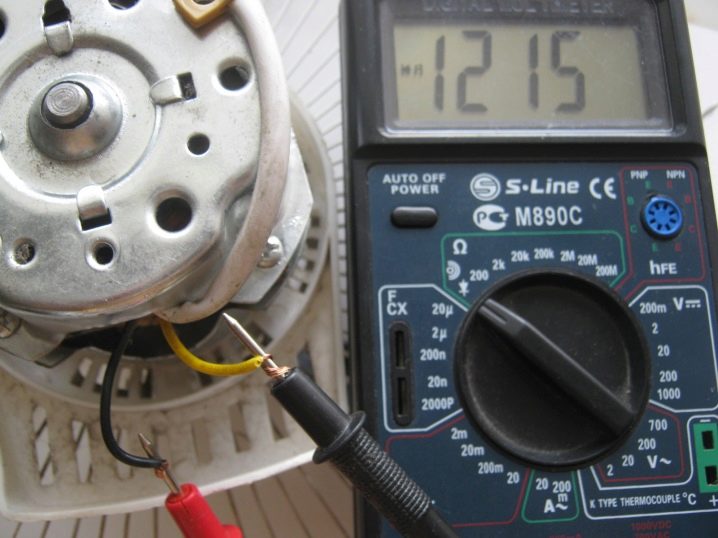

Channel fans are a complex electromechanical device, so disassembly and repair of products should be done only by masters professionals. However, minor malfunctions arising from the operation of the device can be repaired independently. So, if the unit does not turn on, then first of all it is necessary to check the voltage in the electrical network, inspect the condition of the terminals, clean them from dust and tighten the bolts.Then you should make sure that the wheel can rotate freely, and nothing prevents it. In case of blocking, it is necessary to free the shaft, check its free rotation, and if a strong deformation of the blades is detected, replace the device.

If the shaft and blades are OK, you need to check the controls, as well as the electrical safety fittings. If an incorrect protection setting is detected, its operation should be adjusted. Further, if the device has not turned on, it is necessary to ping the motor winding with a tester. Zero resistance indicates that the motor winding is burnt out and needs to be rewound. However, in some cases, rewinding wires on the rotor and stator no longer helps, and the engine has to be changed. When performing diagnostics, it should be clearly understood that rewinding or complete replacement of the electric motor should be carried out only by masters on special equipment.

Channel models for round ducts are reliable and durable devices and allow for a small amount of money to equip the ventilation system with a powerful and efficient fan.

The principle of the channel fan is clearly presented in the video below.