Types of flexible inserts for ventilation and their features

Ventilation in a private house is a rather complicated thing in its structure. It can not be reduced only to pipes and externally visible leads and inputs. There must be other equipment, among which special attention was paid to the flexible insert for ventilation.

Characteristics and options

To create the most efficient air flow, special air-blowing machines are used. Under the action of their pumping occurs much faster and in greater volume. But since these machines inevitably contain parts moving during operation, vibration also arises. One of the ways to combat the negative effect of vibrational oscillations is just a vibration insert for ventilation systems.There are special types of such devices.

The flange insert format is formed, as already follows from its name, by a pair of flanges. In the interval from one to the other flange is a flexible part. Its properties are designed so that the design can move a little. As a result of the movement, the bulk of the energy of the vibration oscillations is discharged into the air. The flange itself does not move — its movement cannot be fixed even by the most accurate instruments. As a soft part, a self-adhesive sealing tape based on polyethylene is preferably used. Also in the design includes textiles or neoprene.

To make the flanges themselves, use the following materials:

- aluminum;

- aluminum foil;

- steel with an external zinc layer (applies only to networks that divert smoke).

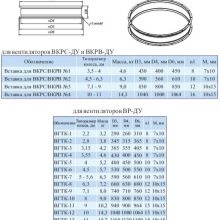

Modern flexible inserts have a device that has worked for decades. Constructors achieve above all the optimal balance of simplicity and efficiency. But a universal solution has not yet been proposed - it follows even from the instructions of GOST.The generally accepted approach is that for all types of fans bend inserts should be chosen specifically. There is still a difference in geometry: products are produced in both round and rectangular configurations in order to provide docking with connectable nozzles and air ducts.

The vast majority of flanges are made of steel, because this metal is the most durable and practical. Inserts are mainly calculated for pumping air, the temperature of which is not lower than -30 and not higher than +85 degrees. For this purpose, the materials already described and their combinations are sufficient. But in reality there are situations when such characteristics are not enough. Special types of inserts can be designed for heating to 650 degrees, for this purpose, the flanges are made of stainless steel grades, and fiberglass is used in the connecting link.

How to pick and use?

In order not to be mistaken with the definition of the type of insert, it is necessary to focus on the so-called fan number and its type. These elements can be placed on the input and output. The main dimensions that you need to pay attention to - this is the length and cross section.It should be borne in mind that not all inserts are mounted on the pipes. Many of them are mounted in the gaps between the individual sectors of the ducts, because there too it is necessary to weaken the vibration processes.

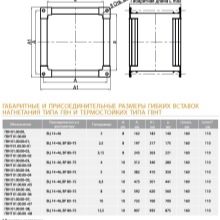

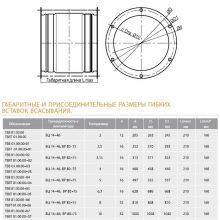

The greater the flow of air that passes through a separate segment of the pipeline, the higher the intensity of vibration. Therefore, it is necessary to carefully calculate all the parameters. Another option is inserts that compensate for thermal expansion. Thanks to them, the problem of protection against temperature distortion of the structure is effectively solved. A typical installation involves attaching the insert from one end to the vent, and from the other end to the duct.

By a similar principle, the connection is also organized with a nipple device. To assess how well the vibrating inserts are mounted, you need to check them in operation. Specialists should have with them special measuring instruments that record vibration levels and loudness of sound. It is very important that these indicators are recorded simultaneously. And one more thing: the test should be carried out under any possible operation modes of the equipment,guaranteed to eliminate unpleasant surprises.

The rectangular insert is intended for a place where air is forced from outside. It is mounted at the intersection of the exhaust fan and air duct. But the round part must be bought for installation at the places where the suction duct of the fan and the air duct are connected. Noteworthy are the characteristics of the material of self-adhesive sealing tapes used in air ducts.

According to the instructions of GOST and the requirements of practice, this material and the structures made from it should allow:

- seal the seams of the elements;

- make impermeable joints of individual sections;

- improve the efficiency of the supply and exhaust systems.

A very important point - the minimum propensity to absorb water. The tape should not be saturated with it more than 2% of the mass. At the same time, resistance to water, ultraviolet and atmospheric oxygen is obligatory. Another nuance - resistance to lubricating oils and the ability to work in a chemically aggressive environment. At temperatures from -50 to 100 degrees, the tape must act flawlessly, without losing any mechanical strength or plastic properties.

One of the sides of the interflange glued elements is covered with a special adhesive. Its recipe and distribution must be such that it is easy and convenient to fix the structure. This does not relieve consumers of the obligation to clean and degrease the surface in advance. Modern manufacturers widely use neoprene, which perfectly holds back both water and heat. When buying it is worth wondering how the product complies with fire safety standards.

More information about the properties of self-adhesive tape used in ventilation systems is described in the video below.