Characteristics, types and use of rivets

Exhaust rivets are quite common fastening material and are widely used in many areas of human activity. The parts have replaced the outdated methods of riveting and are firmly in use.

Purpose

The rivets are used to join the sheet material and require access to the working surface from one side only. This is one of their main differences from the traditional "hammer" models. The mounting of the rivets is made into the drilled hole with the help of a special tool, which can be both manual and pneumatic. Connections made with exhaust rivets are very strong and durable.In addition, parts are easy to install and are highly resistant to the aggressive effects of chemicals, high temperatures and humidity.

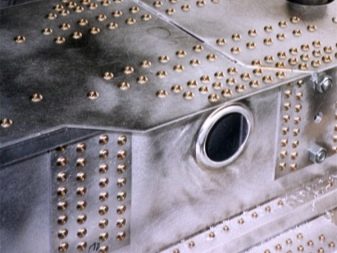

Due to its versatility and reliability, the scope of application of rivets is quite extensive. Parts are actively used in shipbuilding, aircraft engineering and mechanical engineering, the textile industry and construction. When working on objects of increased danger, rivets act as an alternative to welding joints. In addition, rivets are widely used in the repair of parts and mechanisms in hard-to-reach places and fire hazardous objects. In addition to connecting elements from ferrous and non-ferrous metals, exhaust rivets are able to connect plastic and textiles in any combination. This allows them to be widely used in electrical works and actively used in the manufacture of clothing, textile consumer goods and tanks.

Advantages and disadvantages

High consumer demand for exhaust rivets due to near indisputable advantages of these hardware.

- Easy installation due to the need to access the connection only on the front side.This favorably distinguishes these hardware from threaded nuts, for installation of which access is required on both sides. In addition, threaded fasteners tend to loosen over time and loosen the connection.

- The low cost of exhaust rivets allows you to create a reliable and durable fastening, without saving on material.

- A wide range of sizes greatly facilitates the choice of fasteners.

- The ability to combine materials of different structure and properties greatly expands the scope of application of hardware.

- High strength and durable connection. When complying with the rules of installation and careful operation, the service life of rivets is equal, and sometimes exceeds the service life of the fastened parts.

The disadvantages include the need for pre-drilling, misalignment of the connection and the application of significant efforts when riveting by hand. In addition, the models have a one-time purpose and can not be reused.

Manufacturing materials

A wide variety of materials are used as feedstock for exhaust rivets. This allows the use of hardware in almost all types of construction and repair works.For the manufacture of rivets use a number of materials, each of which has its own strengths and weaknesses and determines the place of installation of future products.

Aluminum

Often use its anodized or varnished modification. Aluminum rivets are lightweight and low cost, however, in terms of strength, they are somewhat inferior to steel models. Products are used for bonding light metals, plastics and are widely used in electrical engineering.

Stainless steel

Also used in several modifications. Thus, the brand A-2 is considered one of the most resistant to rust and is used for mounting parts when performing outdoor work. While A-4 has no equal in resistance to acidic environment and is widely used in chemical industries.

Galvanized steel

It has high anti-corrosion properties and provides a reliable connection. However, if one of the elements to be joined has mobility, galvanized parts wear out quickly.

Copper alloys

Widely used in the manufacture of rivets. The most popular is Monel - an alloy consisting of 30% copper and 70% nickel.Sometimes bronze is used as a rod in copper models. The disadvantage of copper elements is their high cost and the risk of green plaque during oxidation.

Polyamide

Used for the manufacture of rivets used in light industry and tailoring. The material does not have a special strength, but it can be painted in any color and looks good on products.

Optimally, all rivet elements should be made of the same material. Otherwise, the risk of galvanic processes, during which the more active metal destroys the weaker, increases. The principle of compatibility must be guided in the selection of hardware for certain materials. For example, a highly undesirable bond of copper and aluminum, while copper behaves quite friendly with other metals.

Kinds

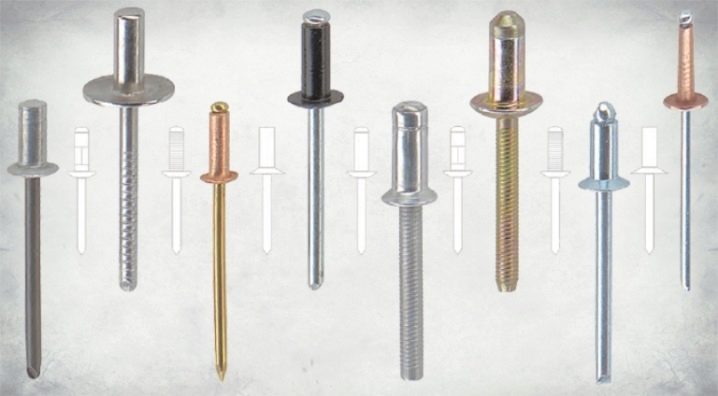

The type of hardware is selected in accordance with the requirements for the connection. Due to the fact that the modern market of fasteners represents exhaust rivets in a wide range, it is not difficult to choose the necessary element. Depending on operational characteristics, the hardware is subdivided into several types.

- Combined models considered the most common type. Hardware is able to provide permanent connection of especially solid parts subjected to mechanical, weight and vibration loads.

- Hermetic models have a fairly narrow specialization and are widely used in shipbuilding industries. The design feature of deaf models is a sealed end of the rod. Products can be made of stainless steel, copper and aluminum.

- Multi-clamp models they have several rasklepochnyh sites and are installed in moving structures when it is necessary to connect three or more elements. Such a site is located between two adjacent elements, and installation is performed using an air pistol.

In addition to traditional models, there are reinforced options for rivets, the manufacture of which uses a more durable material with thickened walls.

Typical sizes

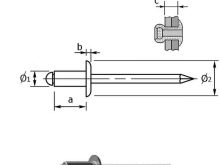

According to GOST 10299 80 form, the sizes and diameters of the heads and shanks of rivets are strictly regulated. This allows you to systematize the use of hardware, as well as simplify the calculation of the parameters of parts and accurately determine their number.The reliability and durability of the connection depends on how true the calculations will be. One of the main parameters of rivets is their length, which can be calculated using the following formula: L = S + 1.2d, where S is the sum of the thickness of the elements to be joined, d is the diameter of the rivets, and L is the required length of the hardware.

The rivet diameter is selected by 0.1-0.2 mm less than the drilled hole. This allows you to freely position the part in the hole, and, by adjusting its location, rivet. Typical diameters of exhaust rivets are 6, 6.4, 5, 4.8, 4, 3.2, 3 and 2.4 mm. The length of the rivets varies from 6 to 45 mm, which is quite enough for joining materials with a total thickness of 1.3 to 17.3 mm.

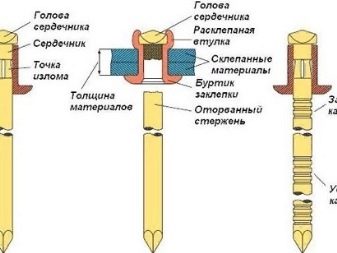

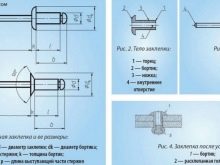

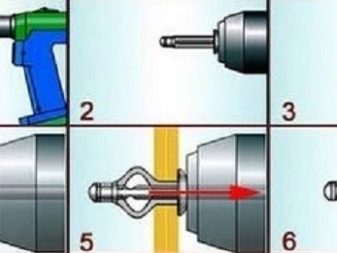

Design and principle of operation

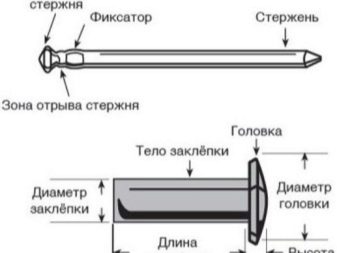

Exhaust rivets are produced in strict accordance with DIN7337 and are governed by GOST R ICO 15973. Structurally, the parts are composed of two elements: the body and the rod. The body consists of a head, a sleeve, a cylinder and is considered to be the main element of the rivet that performs the fastening function. Some hardware has a cylindrical base sealed tightly. The head of the body can be equipped with a high, wide or hidden rim.

The first two provide the most reliable connection, however, from the front side they will be clearly visible. The secret is not distinguished by such high reliability rates as high and wide, but is also widely used in construction and repair. This is due to the fact that the height of the head of the blind rim does not exceed 1 mm, which makes the hardware almost invisible on the fastened surfaces. The rod (core) is an equally important part of the rivet and looks like a nail. On the upper part of the element there is a head and a retainer with a separation zone located between them, along which the rod breaks off during installation.

Exhaust rivets are available in various sizes. The numerical value of the marking of the hardware means the diameter of the cylinder and its length. Therefore, its dimensions are decisive when choosing fasteners. Both values are indicated by the “x” sign, and in front of them it is written what alloy the cylinder is made of. Thus, the AlMg 2.5 4x8 marking will indicate that the hardware is made of a magnesium-aluminum alloy, the outer diameter of the cylinder is 4 mm, and the length is 8 mm. The rivet rod is made of steel and serves for unraveling the joint; when installed, it is pulled out and broken off with the help of a pneumatic riveter or pliers.

The exhaust rivet works quite simply: A hardware is inserted into a through-hole, pre-drilled in both sheets. After that, the sponge of an airgun abut against the rivet rim, clamp the rod and begin to pull it through the body. At the same time, the rod head deforms the body and tightens the materials to be joined. At the time of reaching the limit value, the rod breaks down and is removed. You can use the product immediately after installation.

Installation

The installation of exhaust rivets is so simple that it doesn’t cause difficulties even for beginners.

A prerequisite for mounting is only the presence of a riveted tool and compliance with the sequence of work.

- The first step will be marking on the front side of the upper part of the parts to be joined. The distance between two adjacent rivets should not be less than five diameters of their heads.

- Drilling holes must be done with a small allowance.

- Deburring is performed on both sides of each part. If access to the closed side is restricted, removal of a burr on it can be neglected.

- The installation of the rivet should be done in such a way that the shank is located on the front side.

- The grip of the rod by the riveter and the operation of the pneumogun should be carried out smoothly and with sufficient force at the same time.

- The remaining part of the rod, if necessary, cut off or bite off with nippers. In the case of an inaccurately performed breaking of the rod, the head can be processed with a file.

Useful tips

In addition to the general algorithm of work, for each individual material has its own small subtleties of installation. So, when joining materials of different thickness, the rivet should be installed from the thin side. This will allow the reverse head to form a thicker flattening and increase the reliability of the connection. In the absence of the possibility of such an arrangement from the side of thin material, it is possible to put a washer of the desired diameter. Such a gasket will not allow the pushing of a thin layer and will not allow the surface to deform.

When joining hard and soft materials it is recommended to use hardware with a high side.m, while the opposite head is better positioned on the side of solid material.If this is not possible, then from the side of the soft layer, you can put a washer or use a petal rivet. It is better to combine fragile and thin parts using plastic exhaust rivets or use spacer and radar versions. To obtain a smooth surface on both sides, it is recommended to use rivets equipped with countersunk heads on both sides.

For the formation of a sealed waterproof connection, it is necessary to use closed "deaf" hardware, which can effectively prevent the ingress of dust and prevent the ingress of water and evaporation. When installing the rivet in an inaccessible place, along with the rivet gun, it is necessary to use additional accessories in the form of extension cords to help get closer to the rod.

In addition, when installing hardware, it should be borne in mind that the distance from the element axis to the edge of the parts to be joined must be greater than or equal to two diameters of the head. The connection of loose materials must be accompanied by the installation of an additional sleeve in which the rivet will be installed. When joining tubes with flat surfaces, it is not recommended to pass the hardware through the pipe. The connection will be more durable if only one of the sides of the tube is involved in the docking.

Thus, exhaust rivets are a universal fastening element. They allow you to form a strong and reliable connection in hard-to-reach areas. Also, parts without problems fasten the surface with limited access from the reverse side.

A detailed story about the use of rivets - in the video below.